Belt drive dual gear feeding mechanism of FDM type 3D printer

A 3D printer and belt drive technology, applied to 3D object support structures, metal processing equipment, manufacturing tools, etc., can solve the problems of printing material feeding failure and easy material jamming, and achieve good applicability and reduce material jamming.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The principles and features of the present invention will be described below in conjunction with the accompanying drawings and specific embodiments. The examples given are only used to explain the present invention and are not intended to limit the scope of the present invention.

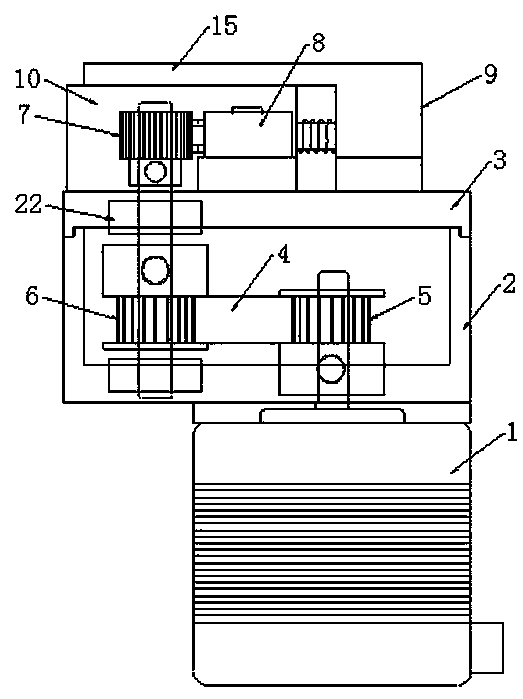

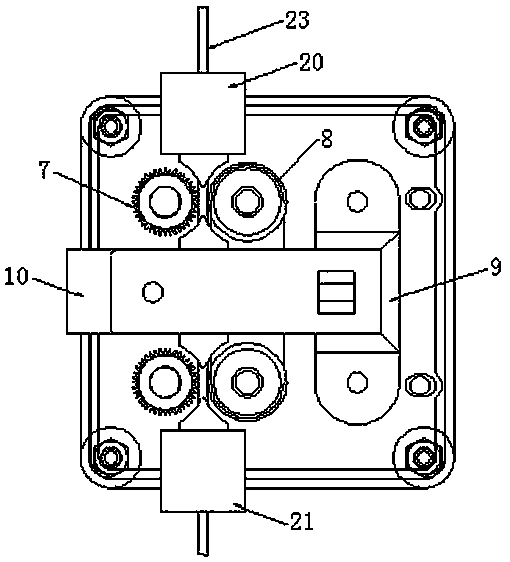

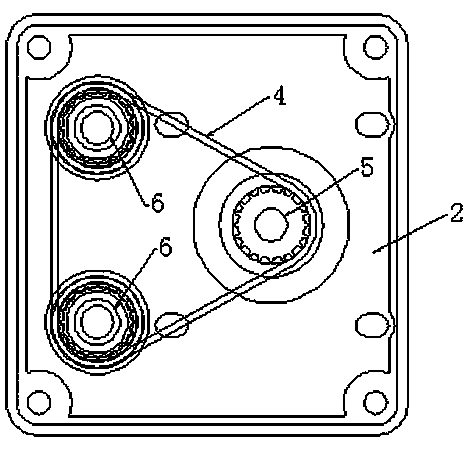

[0037] Such as Figures 1 to 5As shown, the present invention provides a belt-driven double-gear feeding mechanism of an FDM type 3D printer, which includes a stepper motor 1, a box body 2 and a cover body 3, and the bottom of the box body 2 is fixed to the stepper motor The side where the output end of 1 is located and the bottom of the box body 2 is provided with a first through hole for the output end to extend into the box body 2, and the cover body 3 covers the top of the box body 2 At the opening and on the cover body 3, two second through holes are arranged at intervals. The box body 2 is provided with a driving wheel 5 and two driven wheels 6 which are connected by a synchronous belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com