Device capable of continuously drying rod-shaped biomass bales in different shapes and sizes

A biomass and drying technology, used in drying solid materials, drying cargo handling, drying gas layout, etc., can solve the problems of large waste flue gas pressure, inability to dry simultaneously, and complicated processes, so as to avoid dust accumulation, reduce or Avoiding the deposition of dust, the effect of avoiding the deposition of dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Hereinafter, the present invention will be explained in more detail using an example.

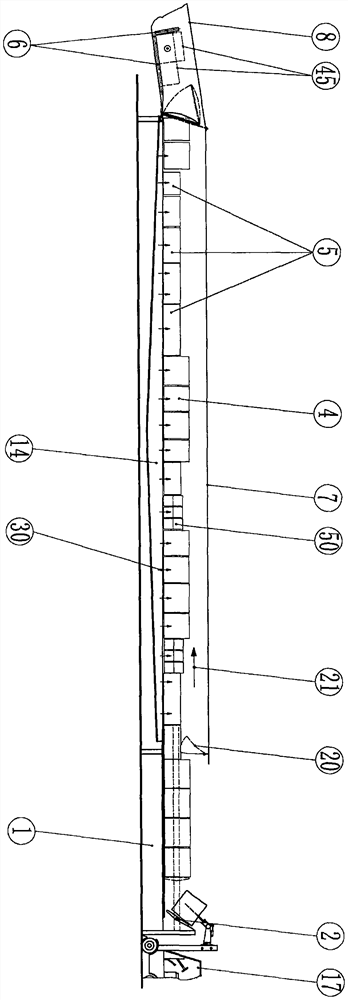

[0028] according to figure 1 The nearly airtight drying channel (7) used for biomass round bales (4) and biomass square bales (5) is about 30m long, and a row can accommodate at most 25 biomass round bales with a maximum diameter of 1.4m ( 4), arranging two rows of biomass bales side by side to process at most 50 biomass round bales (4) at one time. The two rows of the bale feeding bin (1) can also accommodate 6-10 biomass round bales (4) that are not blown into hot flue gas.

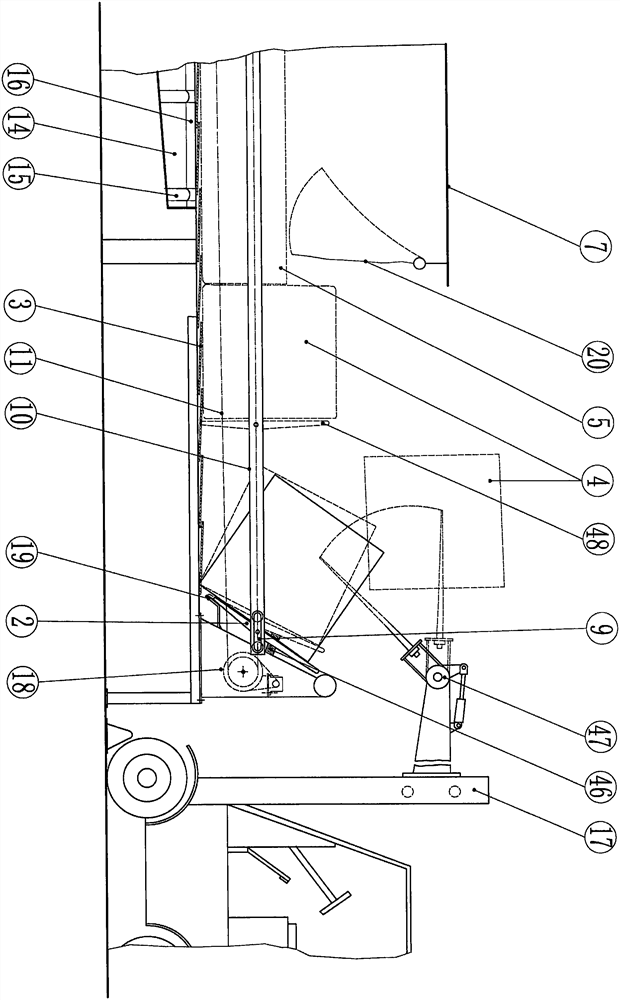

[0029] In the bale feeding bin (1), it is also possible to add biomass square bales (5) and biomass round bales (4) with a length not exceeding 2.4m at the same time, and discharge them on the slide (3). It can also be discharged by hand or using A suitable tool is inserted horizontally into the small biomass bag (50).

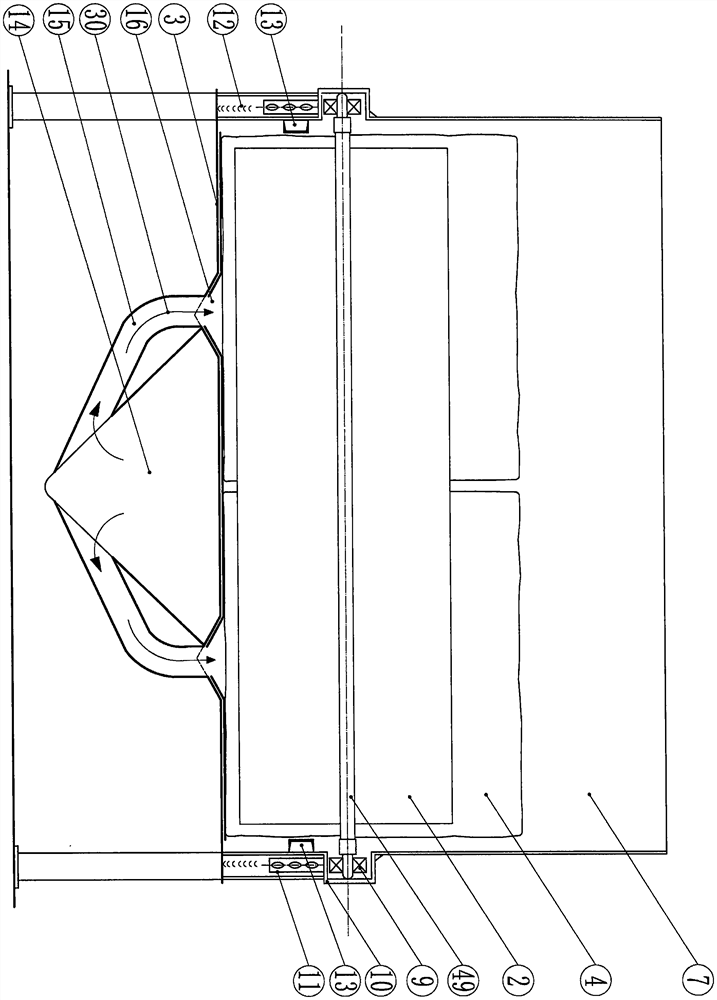

[0030] according to figure 2 As shown, the bale push shield (2) is integrated with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com