Over tensioning and tension-releasing structure for stay cable cable-force

A cable-stayed cable and tension pedestal technology, used in cable-stayed bridges, erecting/assembling bridges, bridge forms, etc. Difficulty and other problems, to achieve good economic benefits, ensure service life, and prevent the effect of pinching the steel strand

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

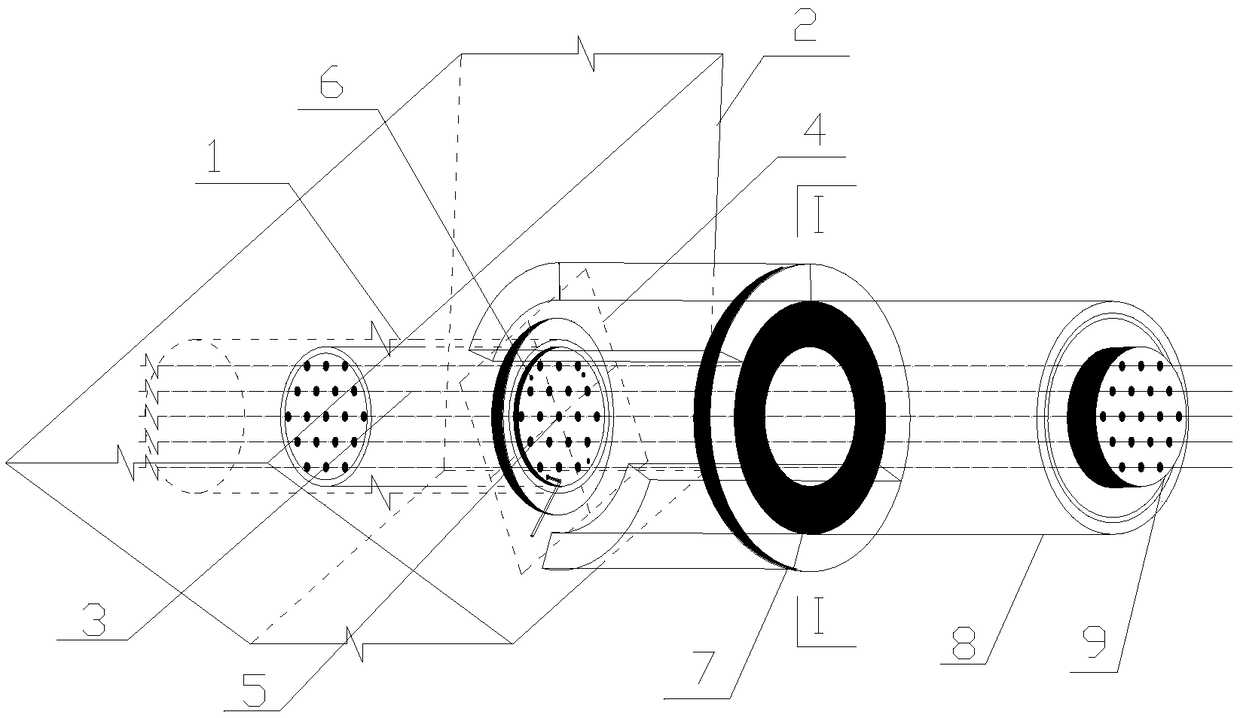

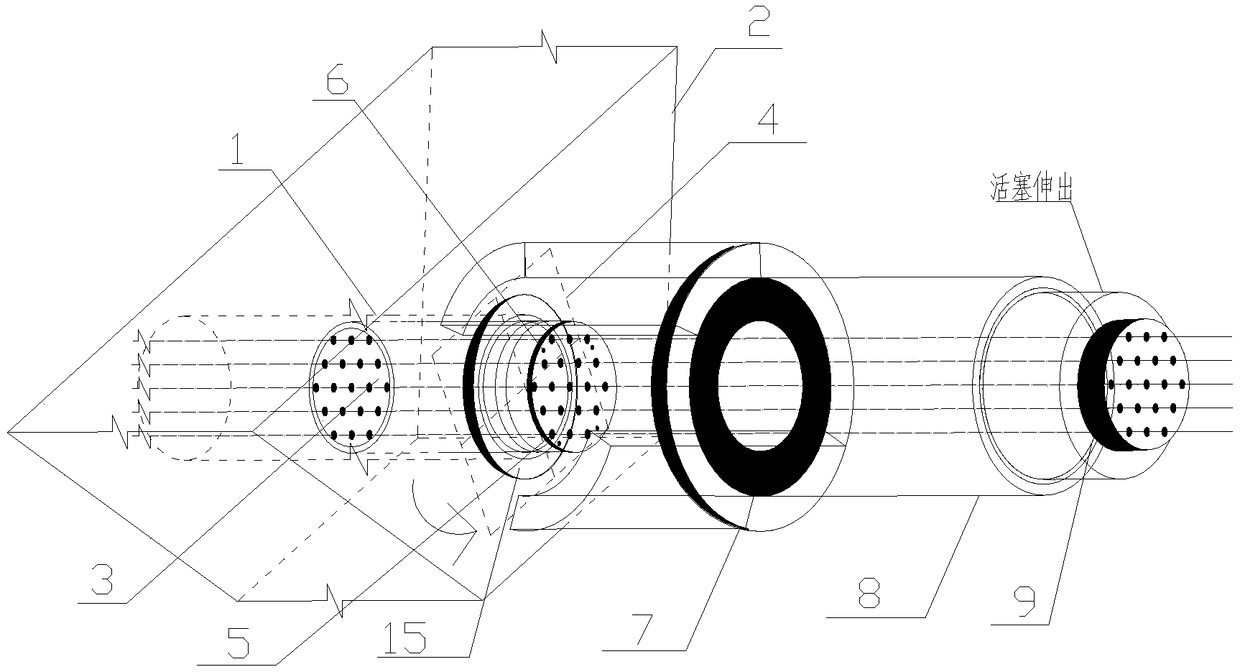

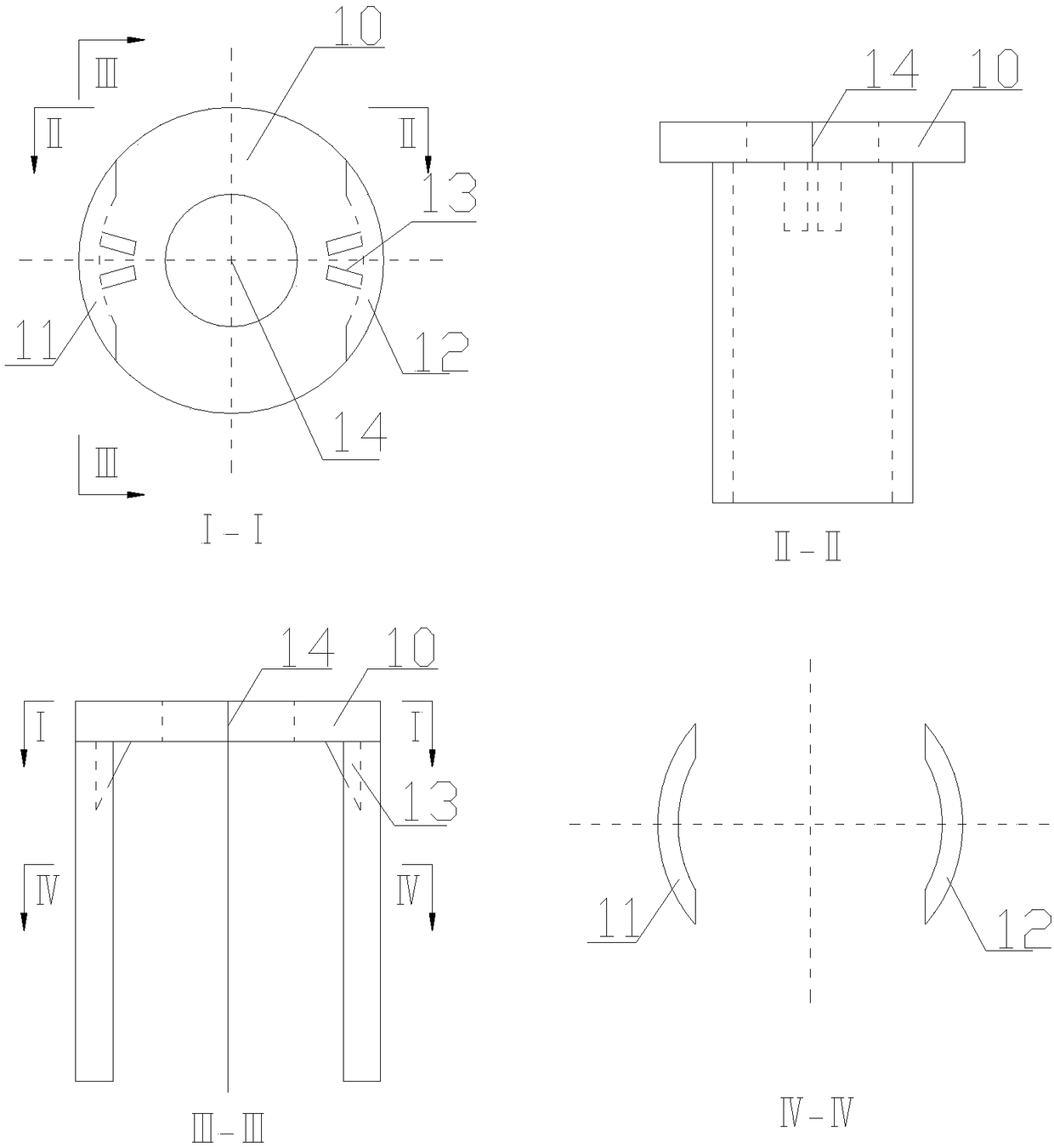

[0021] A stay cable force overtension release structure, which includes a guide tube 1, a partition wall tooth block concrete 2, an anchor tube 3, a guide tube anchor plate 4, a working anchor 5, and an adjusting nut 15. The guide tube 1 is pre-embedded in the box girder In the partition wall tooth block concrete 2, the anchor tube 3 is arranged in the guide pipe 1, and the guide pipe anchor plate 4, the adjustment nut 15 and the working anchor 5 are installed in sequence at one end of the guide pipe 1, and the partition wall tooth block concrete 2 is provided with the adjustment nut 15- The side is fixed with a steel stretching stand 7, the other end of the steel stretching stand 7 is connected to the jack 8, and the other end of the jack 8 is connected to the tool anchor 9; The hole 18 is used to rotate the adjusting nut up and down; the guide pipe 1 is welded, and the welding seam grade meets the requirements of the second-level weld seam; The side arc panel 12 and the tria...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com