A Coke Quality Prediction Method Based on High Potassium and Sodium Contents in Coal Ash

A technology of coke quality and sodium content, applied in coking ovens, complex mathematical operations, manufacturing calculation systems, etc., can solve problems such as unforeseen, complicated operations, unfavorable promotion and application, etc., to reduce coking production costs, expand the selection range, Simple operation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0057] In this embodiment, a 7-meter coke oven of a factory and a corresponding 3200m 3 Take the blast furnace as an example.

[0058] 1) The proportion of high potassium and sodium coal is 20%, K 2 O content and Na 2 The content of O is 1.5% and 0.7% respectively, and K 2 O content ≥ 1.0%, Na 2 O content ≥ 0.5%;

[0059] 2) The reflectance of coal vitrinite used in coke ovens is continuously distributed within 0.8% to 1.5%;

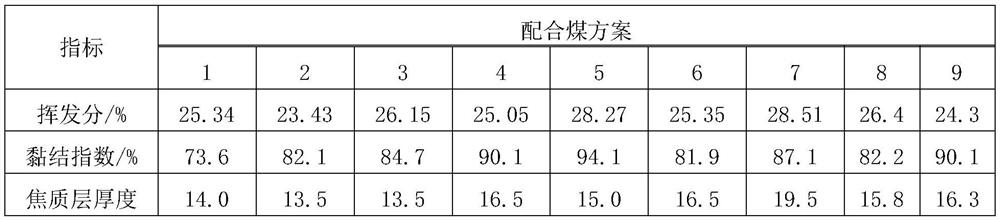

[0060] 3) The volatile content of blended coal is between 24.0% and 30.0%, the cohesive index is between 70 and 95, and the thickness of the coke layer is 12mm to 25mm; the specific values are shown in Table 1:

[0061] Table 1 Data table of related indicators of coal blending scheme

[0062]

[0063] 4) The regression equation is Y=b 0 +b 1 x 1 +b 2 x 2 +b 3 x 3 ,

[0064] Among them, Y is the coke thermal strength index, %;

[0065] x 1 、X 2 、X 3 Match the ash content of coal, Na in ash 2 O and K 2 O content, %;

[0066] Deter...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com