Full-automatic assembly machine track of split conductor plug

A fully automatic and assembly machine technology, applied in the assembly/disassembly of contact parts, etc., can solve problems affecting machine operation efficiency, processing difficulties, fixture errors, etc., and achieve the effects of saving positioning time, reducing overall weight, and convenient positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

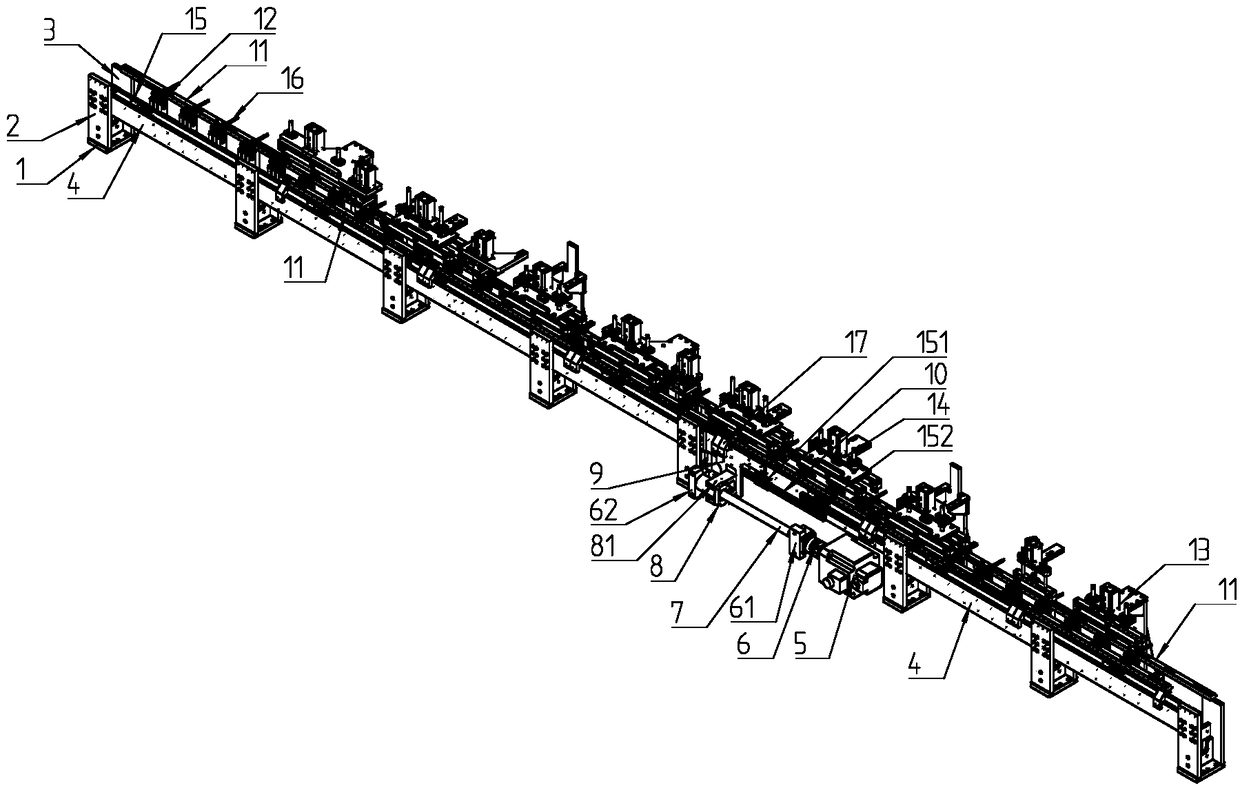

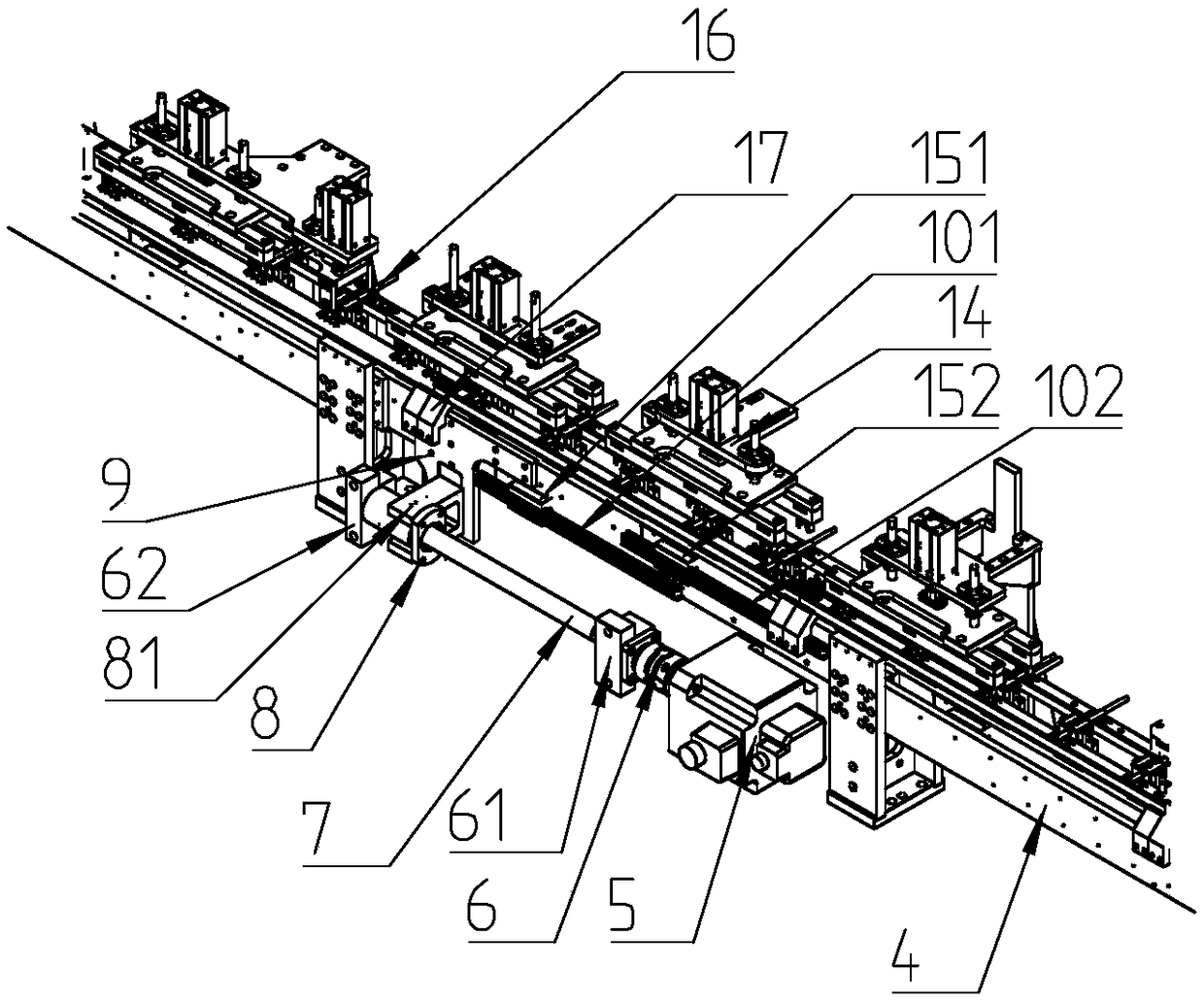

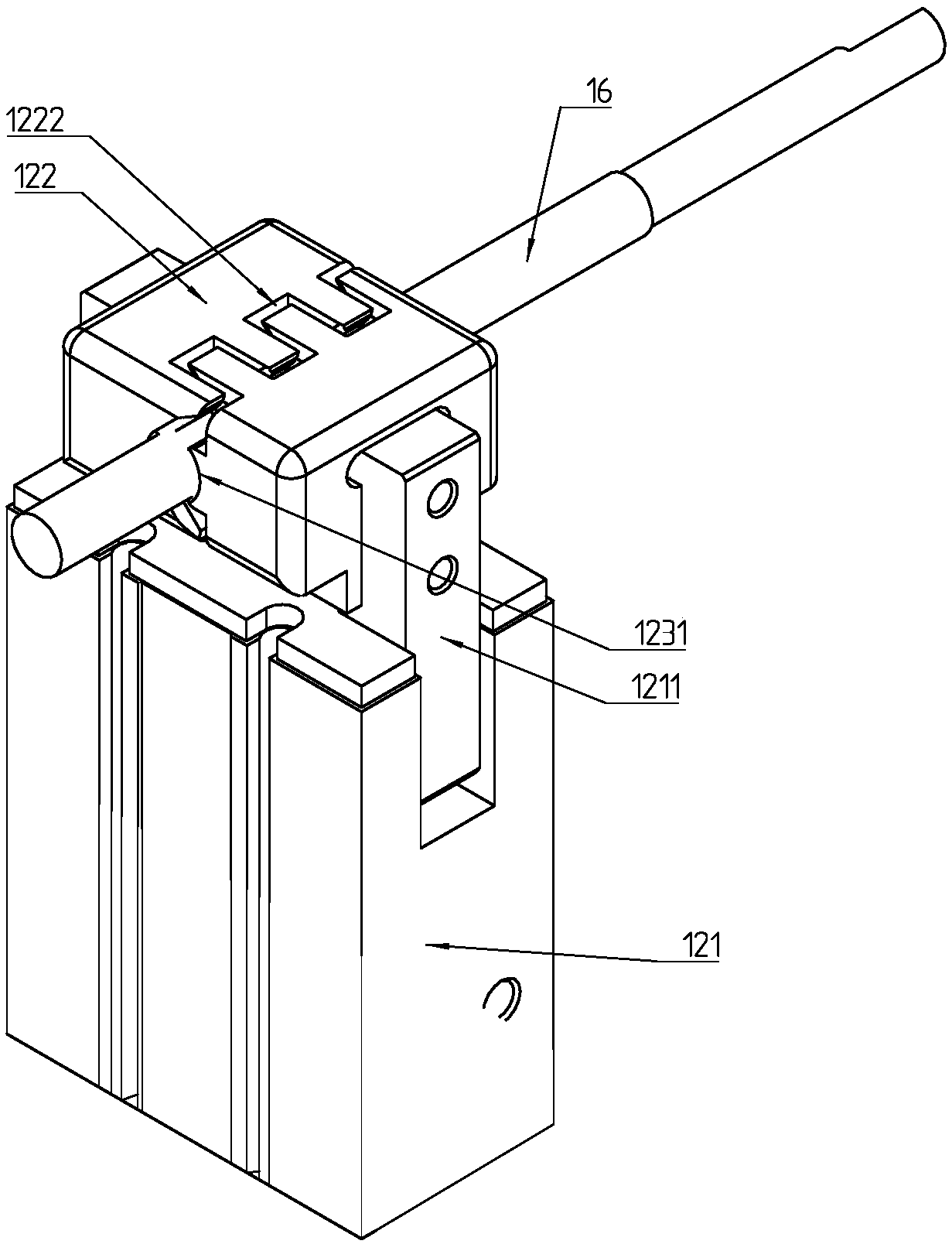

[0027] A multi-core plug automatic assembly machine track, including a frame, the frame includes a track bottom plate 1, a track vertical plate 2 and a track support plate 3 vertically welded to the upper end surface of the track bottom plate 1, and the track bottom plate 1 is fixed on the multi-core On the frame of the line plug automatic assembly machine, the track fixture mounting plate 15 is installed on the track fixing plate 4 through the linear track 10, and the track fixing plate 4 is installed on the track vertical plate 2; the driving device drives the track mounting plate 15 to linearly reciprocate move.

[0028] See Figure 1-Figure 2 , the linear guide rails 10 are arranged side by side and at least two, preferably two in this embodiment, and each linear guide rail is divided into a set number of first linear guide rails 101 and second linear guide rails 102 arranged in parallel to each other. , the lengths of the first linear guide rail 101 and the second linear...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com