Peeling machine for elongated bamboo shoots

A peeling machine, slender technology, applied in the direction of peeling utensils, vegetable or fruit peeling, household utensils, etc., can solve the problems of large fluctuations in the size deviation of the effect of peeling bamboo shoots, human injuries, and heavy workload. Achieve the effect of enhancing the effect of peeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

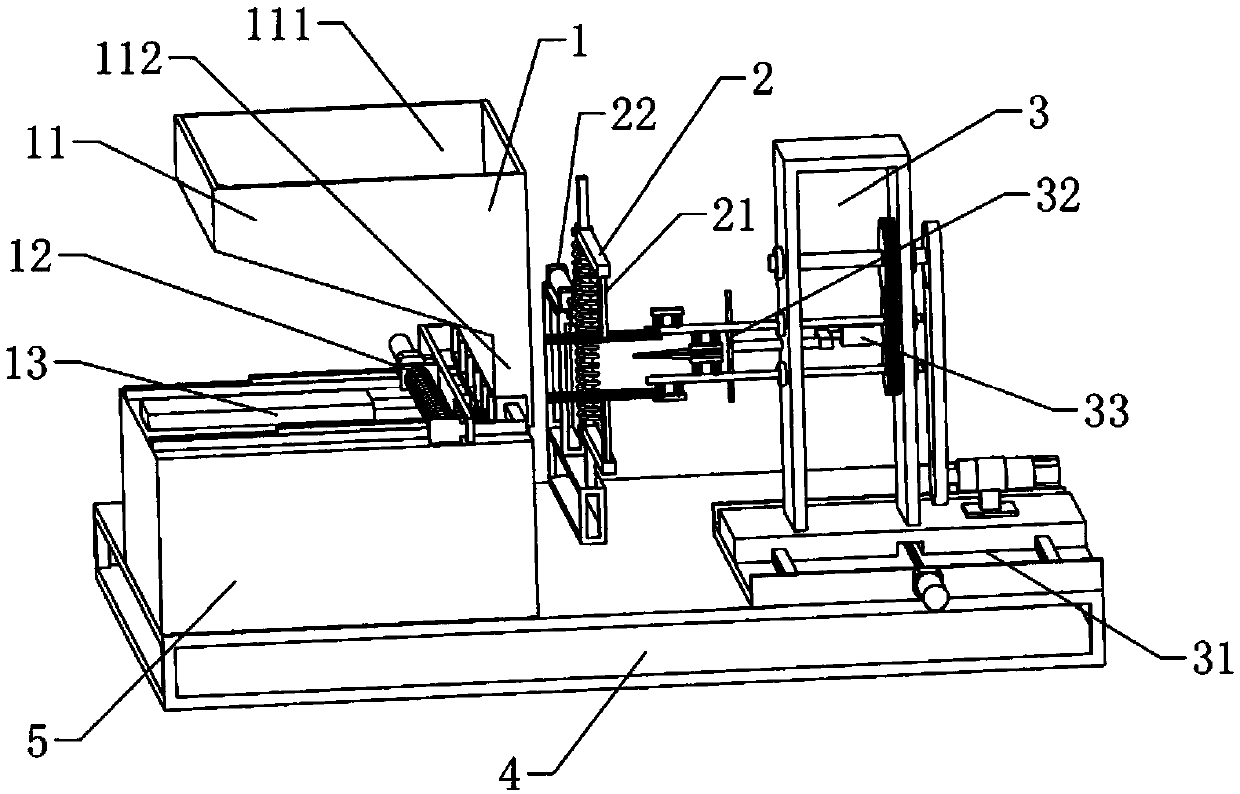

[0023] according to Figure 1 to Figure 4 Shown, a kind of slender bamboo shoot peeling machine comprises: unloading table 1, positioning guide table 2, peeling table 3, frame 4 and control box 5.

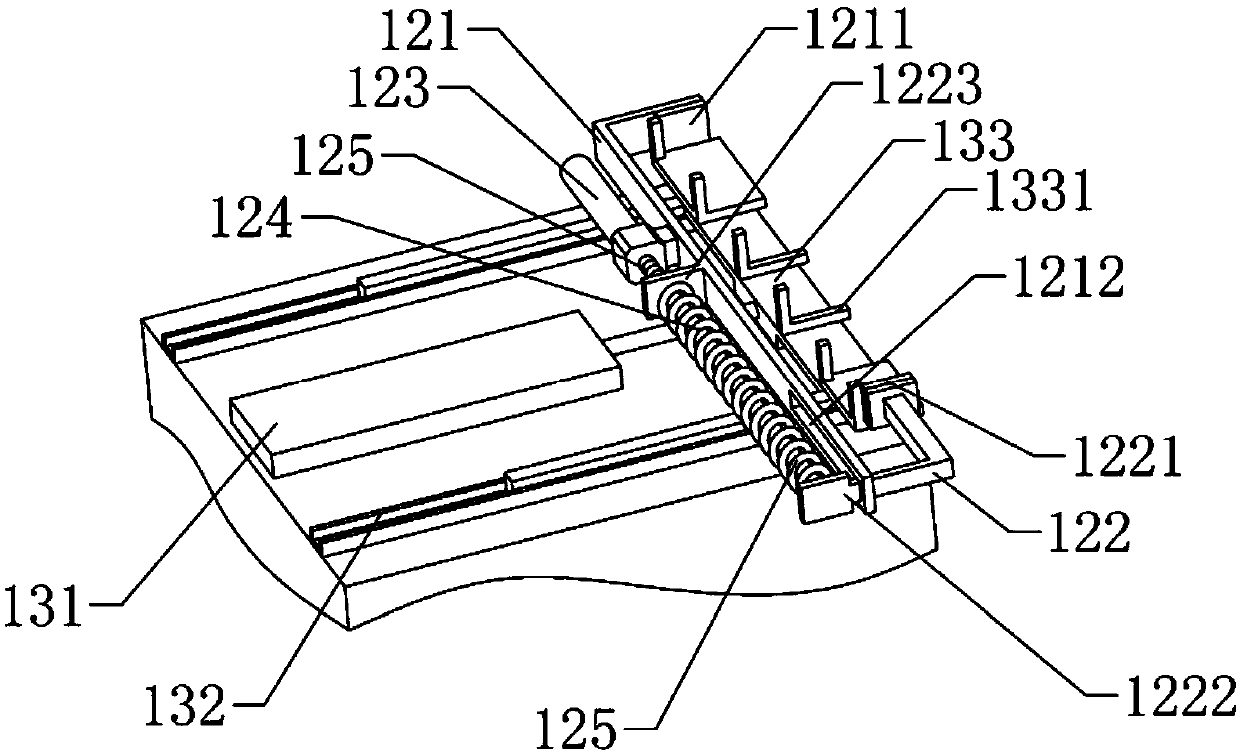

[0024] according to figure 1 , figure 2 As shown, the unloading platform 1 includes a material box 11 , a bamboo shoot head induction positioning mechanism 12 and a pushing mechanism 13 , and the material box 11 includes a storage area 111 and a drop area 112 . The bamboo shoot head induction positioning mechanism 12 comprises, fixed briquetting block 121, sliding briquetting block 122, induction servo motor 123, pressure return spring 124 and pressure control screw mandrel 125, and fixed briquetting block 121 and sliding briquetting block 122 are provided with first pressure respectively. The sensor 1211 and the second pressure sensor 1221, the first pressure sensor 1211 and the second pressure sensor 1221 are respectively arranged at both ends of the drop area 112; the tail of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com