Cut stem preparation method and cut stem and application thereof

A technology for washing cut stems and tobacco stems, which is applied to cut cut stems and their applications, and the field of preparation of cut cut stems, which can solve the problems of rough quality, high shredding rate of cut stems, poor uniformity and the like.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

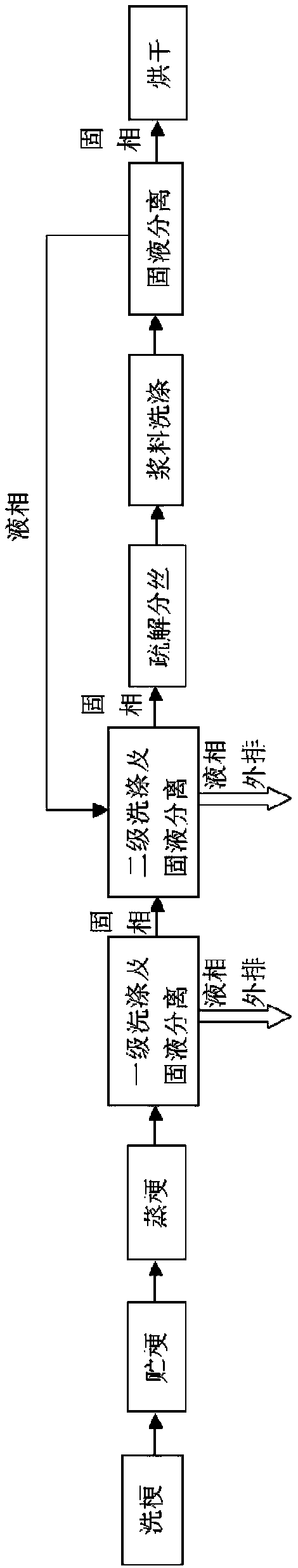

[0080] The preparation process is as figure 1 Shown:

[0081] (1) Put the tobacco stems (Fujian Longyan short stems, 2-5cm in length) into the stem washing machine, and wash the stems with hot water at 68°C-70°C for 10-15 seconds. After washing the stems, the moisture content of the tobacco stems is 30% (W / W) ~ 34% (W / W).

[0082] (2) Insulate and store the tobacco stems obtained in step (1) for more than 30 minutes, and the insulation temperature is still 68° C. to 70° C. After the end, the moisture content of the tobacco stems rises to 34% (W / W) to 40% ( W / W).

[0083] (3) Put the stems obtained in step (2) into the steamer, steam the stems at 85°C-95°C for 15-20 seconds, keep the steam pressure at 0.7-0.85MPa, and increase the moisture content of the stems to 38% (W / W) ~ 43% (W / W).

[0084] (4) Put the tobacco stems obtained in step (3) into a primary washing tank, add clear water at a solid-liquid ratio of 1:5.5 (g / g), mix and stir for 30 minutes, and the mixing temper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com