Herringbone gear slotting processing method based on on-line detection and compensation of symmetry error

A technology of herringbone gears and processing methods, applied in metal processing equipment, gear tooth manufacturing devices, belts/chains/gears, etc., can solve problems such as poor symmetry, achieve high positioning accuracy and automatic clamping, and avoid repeated search. Positive and clamping fixation unstable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

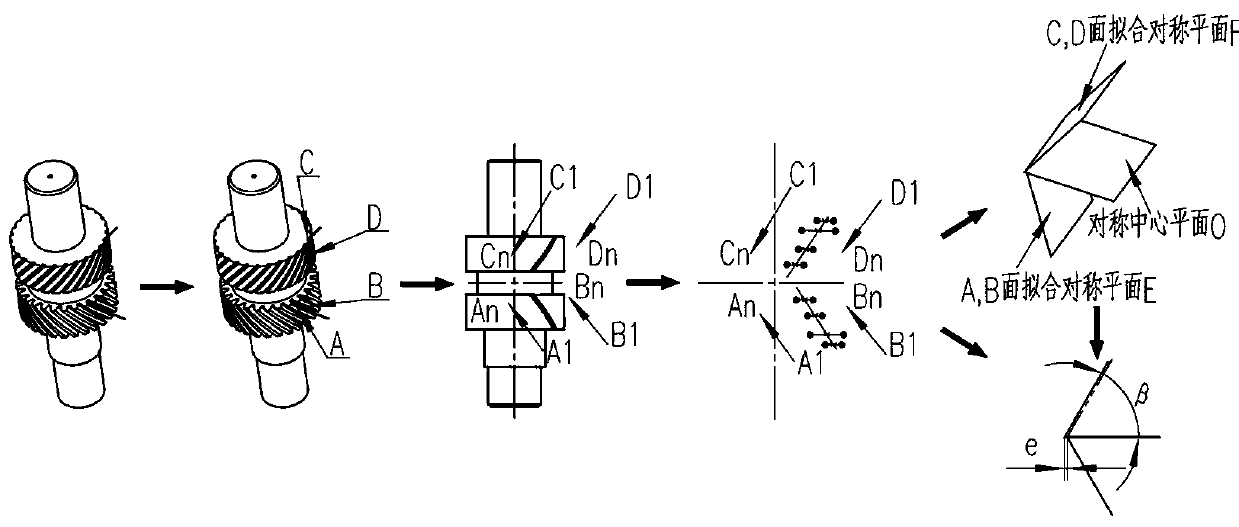

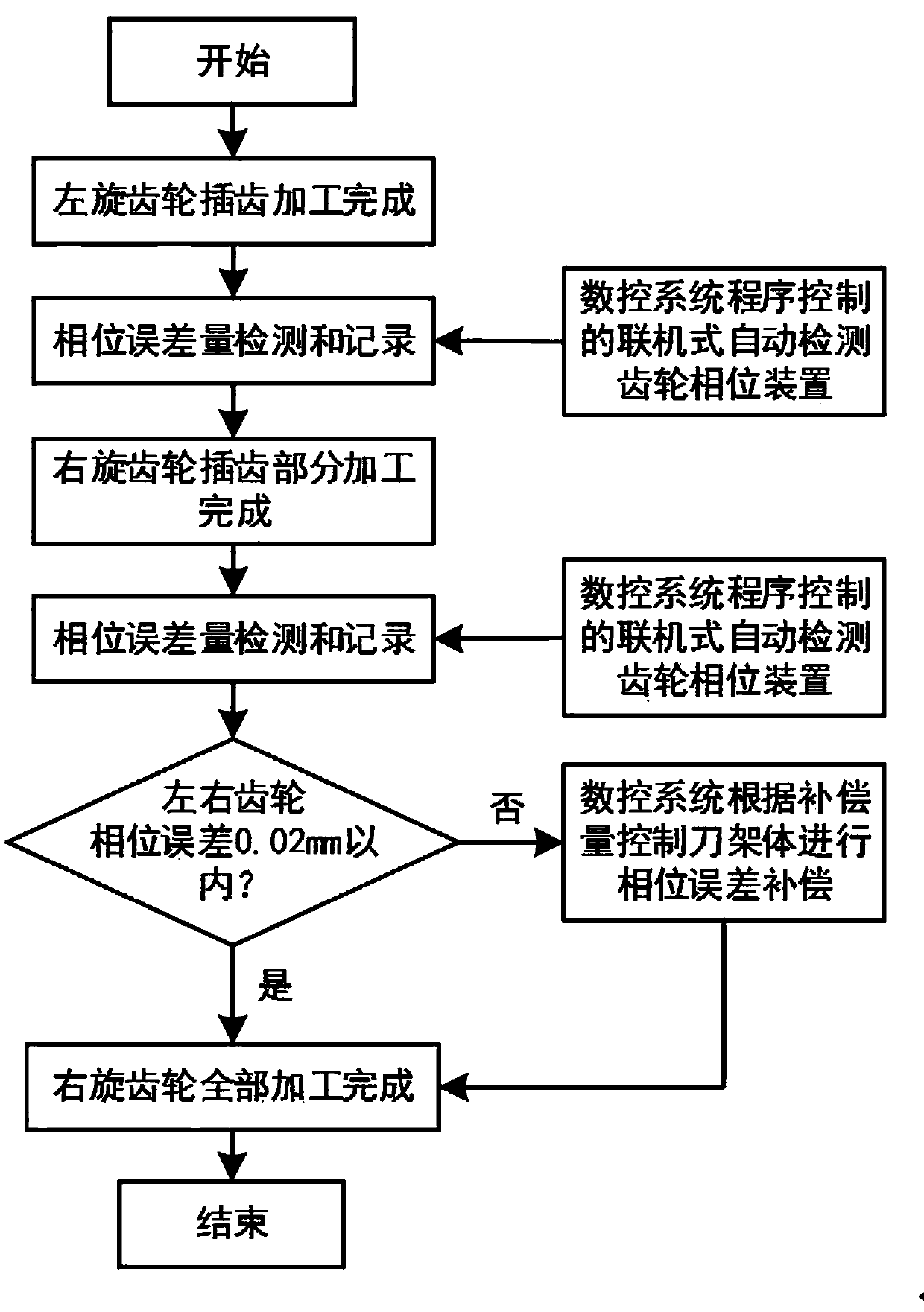

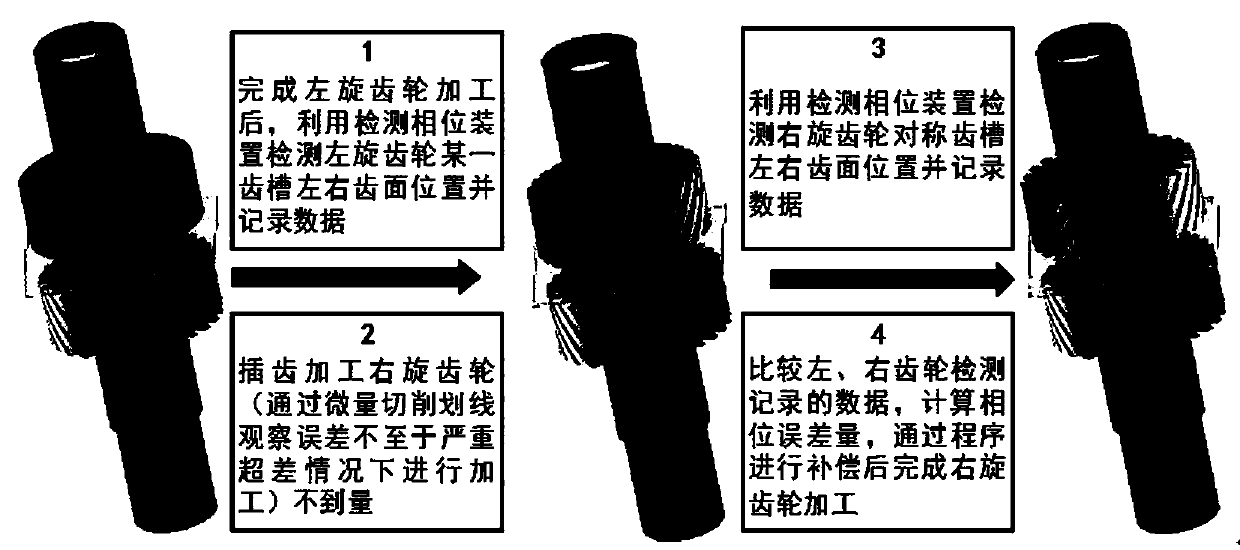

[0032] The technical problem to be solved by the present invention is to provide a herringbone gear slotting processing method based on online detection and compensation of symmetry errors. Based on the spatial plane fitting method, the least square method and the equivalent processing method of symmetric errors, the The mathematical model of symmetry error detection and compensation calculates and expresses the symmetry error of the herringbone gear through the calculation of the mathematical model, and uses the motion axis of the CNC gear shaping machine and the CNC control system to complete the online detection and compensation of the symmetry error. On this basis, the online multi-degree-of-freedom online detection device realizes the online detection and compensation of herringbone gear symmetry errors by developing the NC program for online detection of symmetry errors of herringbone gears, using the fixed-angle processing function and optimized measurement methods. Effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com