Tool and method for electrolytic machining of large-diameter holes arranged at intervals for flushing and pumping liquid

A large-diameter, flushing technology, which is applied in electrochemical processing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of large-diameter holes that are difficult to process, and achieve a reasonable distribution of flow channels and uniform and stable electrolyte Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with accompanying drawing:

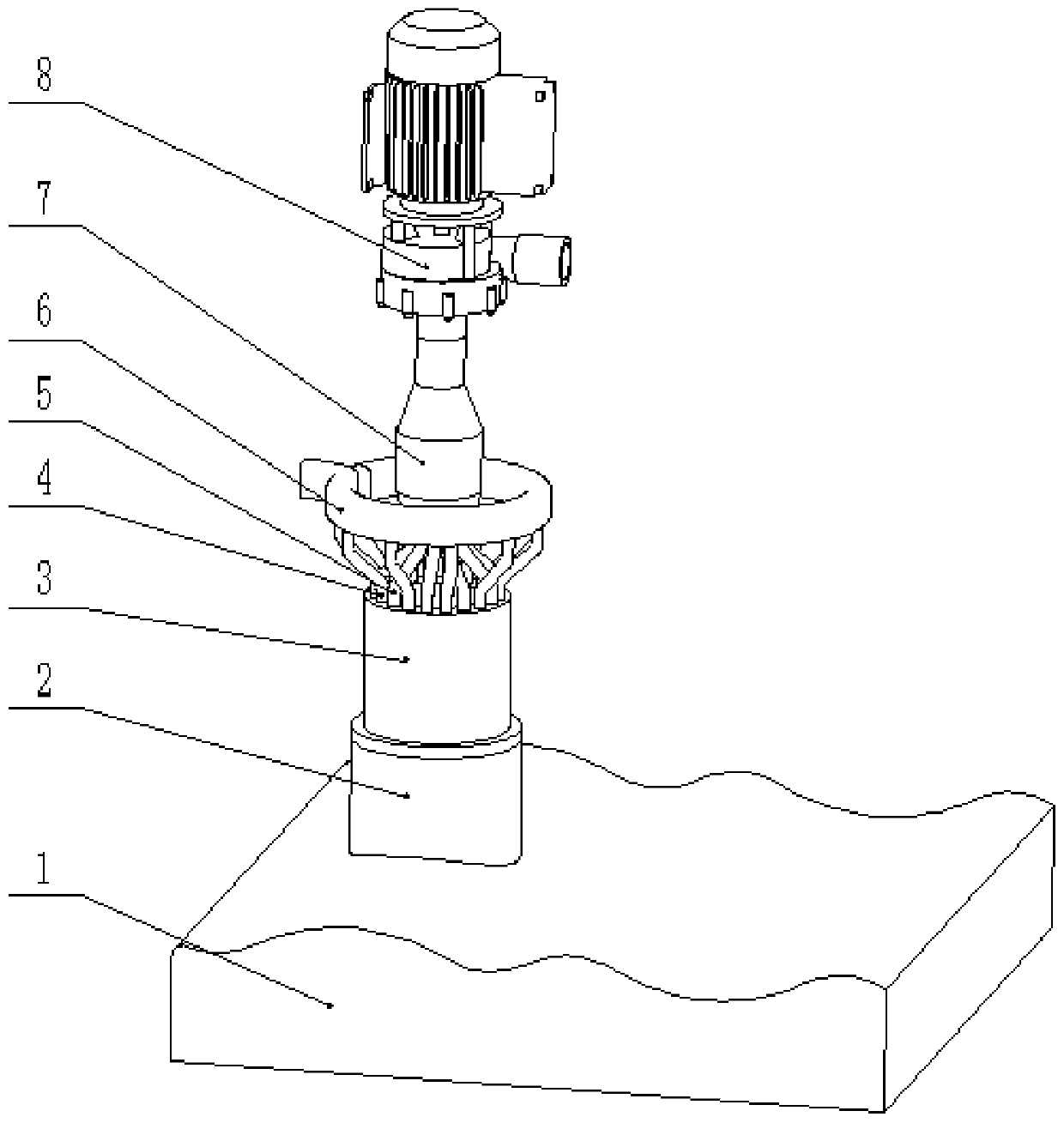

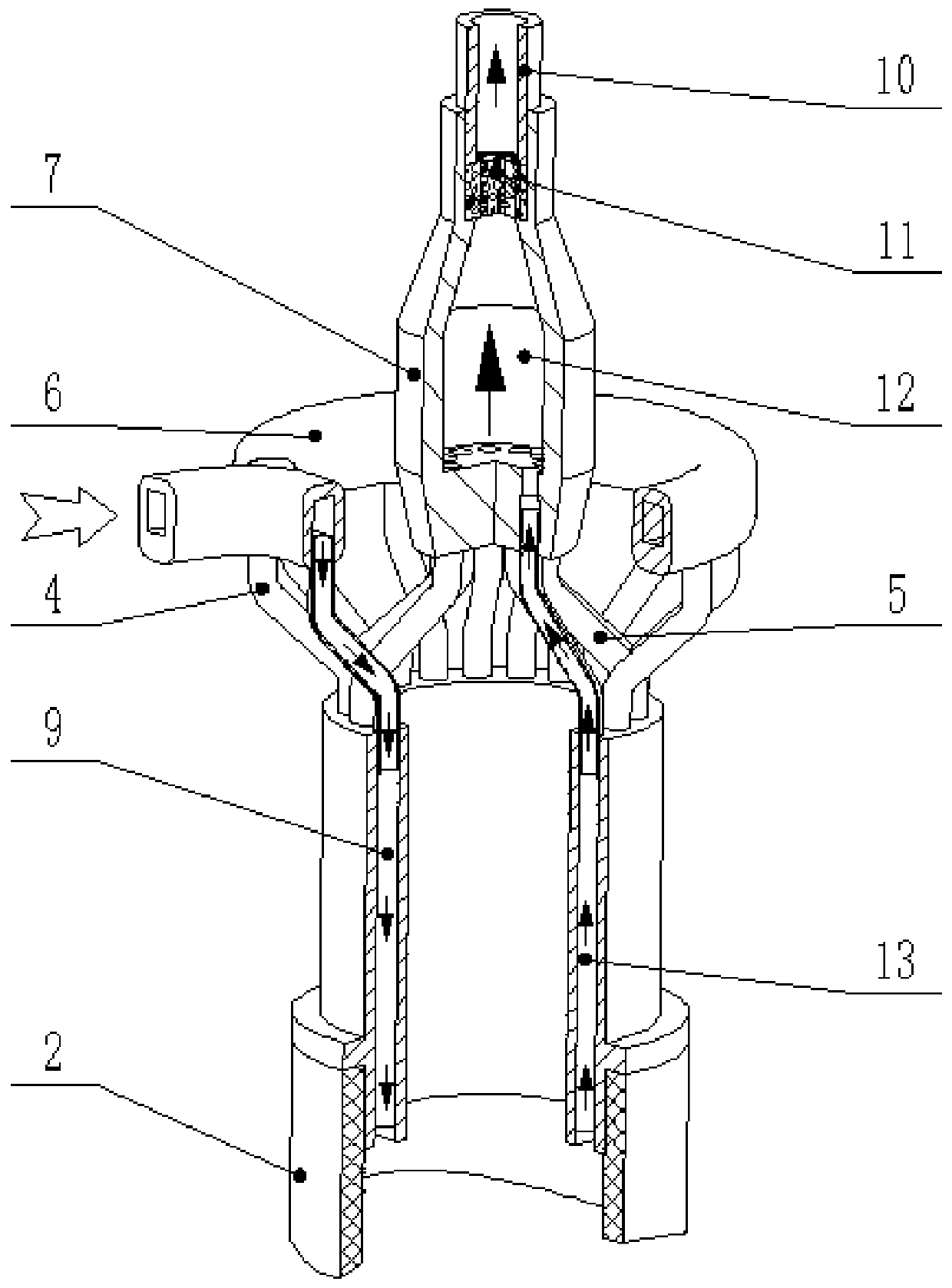

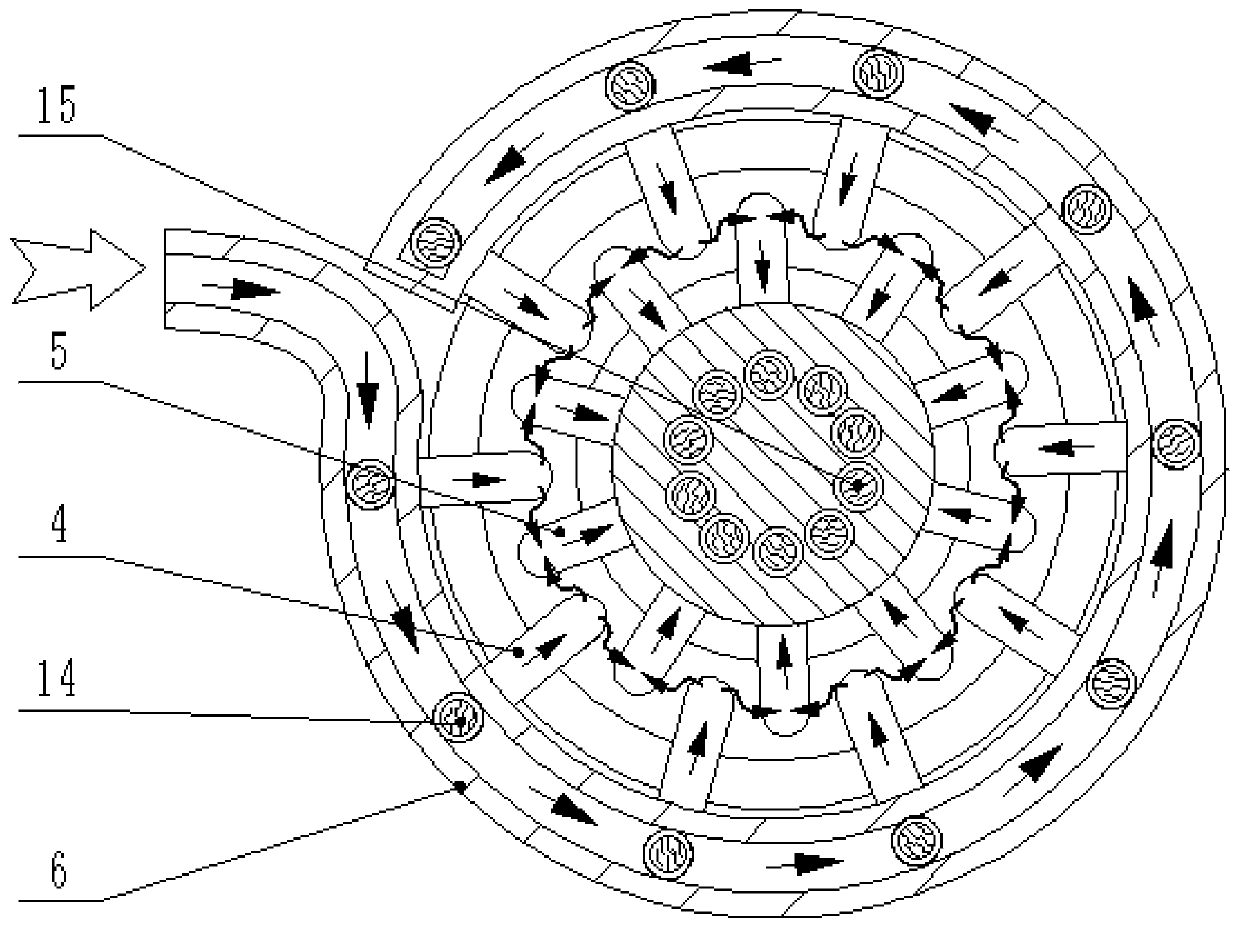

[0028] Such as figure 1 , 2 The shown device includes a flexible sealing sleeve, a tool cathode, a liquid inlet group pipe, a liquid outlet group pipe, an annular liquid inlet pipe, a liquid suction pipe, a suction pump, a pipe joint and a porous metal filter module. One end of the liquid inlet group pipe is inserted into the liquid outlet at the bottom end of the ring-shaped liquid inlet pipe, and the other end is inserted into the cathode liquid supply channel of the tool; one end of the liquid outlet group pipe is inserted into the cathode liquid discharge channel of the tool, and the other end is inserted into the liquid outlet at the bottom of the suction pipe; the flexible sealing sleeve On the outer cylindrical surface below the cathode of the tool; the porous metal filter module is placed above the liquid suction pipe to filter large particles that have not been el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com