Full-automatic welding system for contact knife of frame circuit breaker

A fully automatic welding and frame circuit breaker technology, applied in welding equipment, welding/welding/cutting items, electric heating devices, etc., can solve problems such as low work efficiency, low degree of automation, unstable product quality, etc., and achieve energy saving Effects on Cost, Extended Electrode Life, Increased Efficiency and First-pass Welding Penetration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

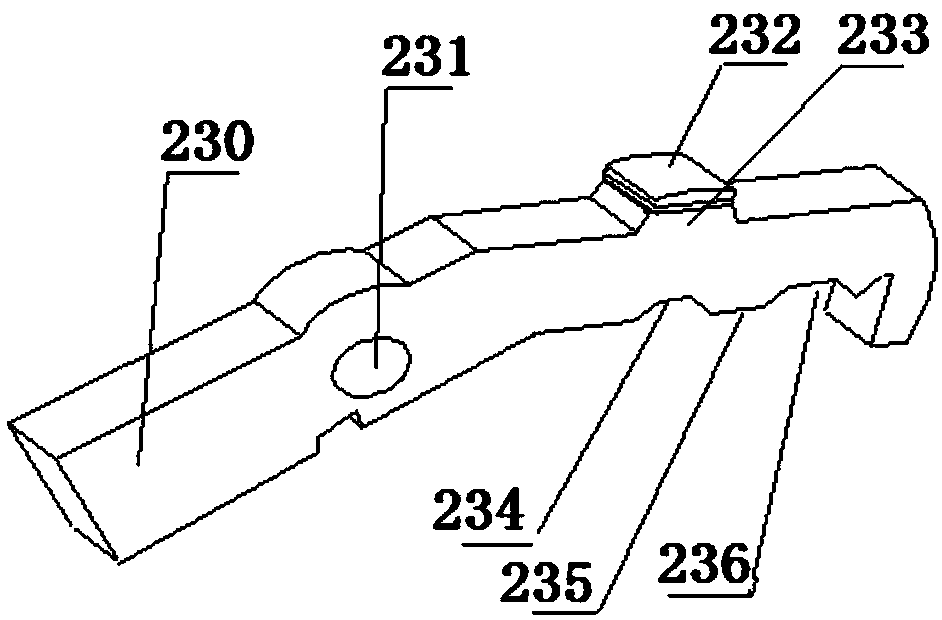

[0039] refer to figure 1 , the welding main body of the present invention is a contact knife 230, and the upper surface of the front section of the contact knife 230 is a trapezoidal upper boss 233; Boss 235 and rear groove 234, rear groove 234 and upper boss 233 positions are opposite up and down, the rear section of contact knife 230 is bent downward, and in the rear part of contact knife 230, there is support hole 231 transversely. The upper boss 233 is a trapezoidal boss with a bottom edge of the lower step of the assembly contact 232 with a depth of less than 1.5mm, and square grooves for soldering pieces and flux (the addition of square grooves to the contact blade 230 is an innovation).

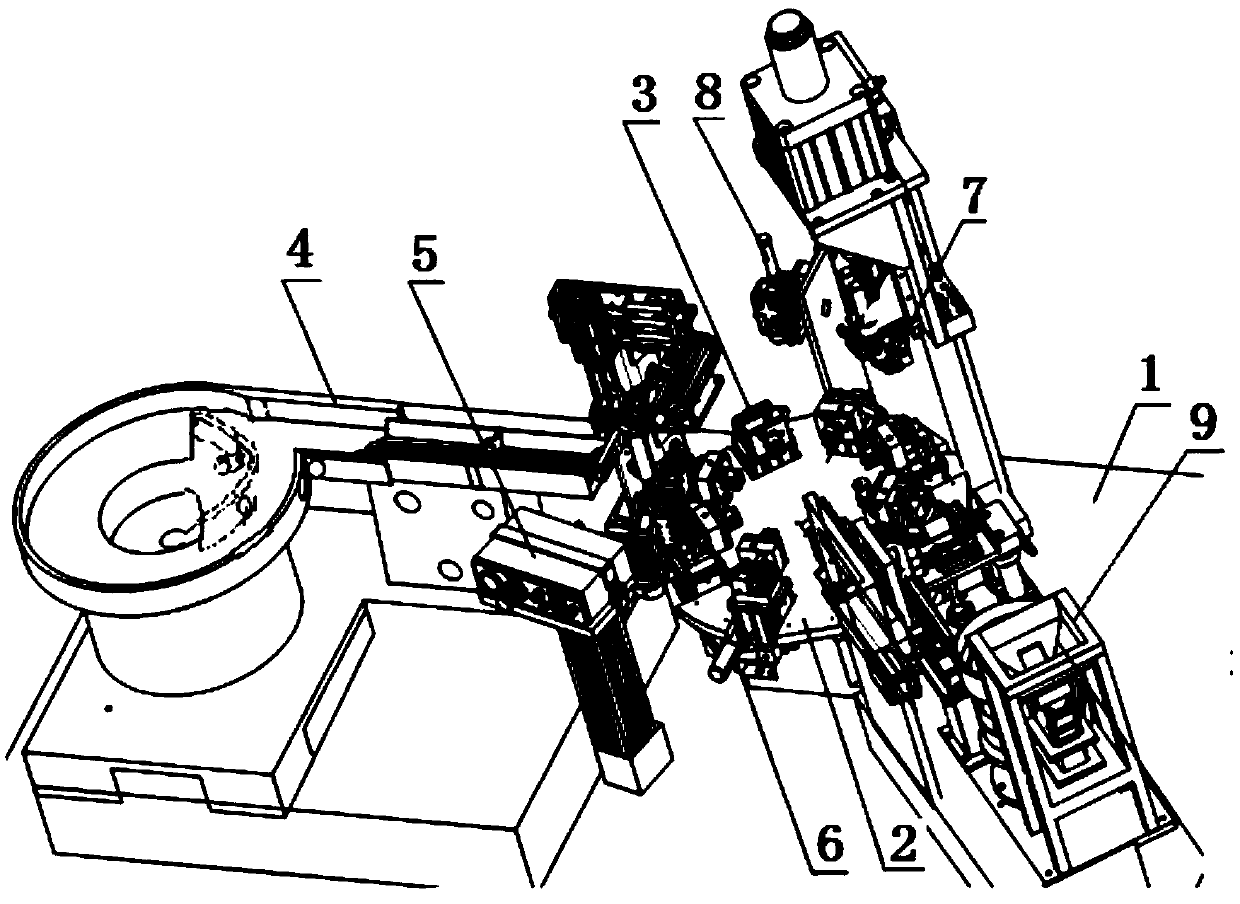

[0040] The purpose of the present invention is to adopt automatic welding and automatic assembly, automatically drop soldering flux from top to bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com