Intelligent assembly line of LED filament lamp

A technology of LED filament lamps and LED filaments, which are used in assembly machines, metal processing equipment, manufacturing tools, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] The technical scheme of the present invention will be further described below in conjunction with the accompanying drawings of the description:

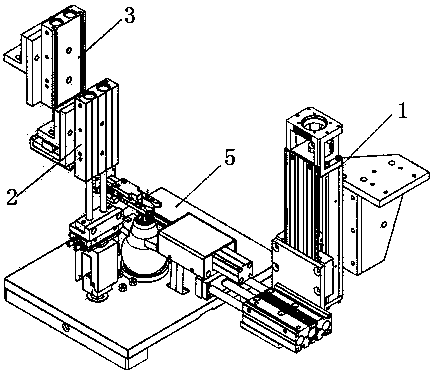

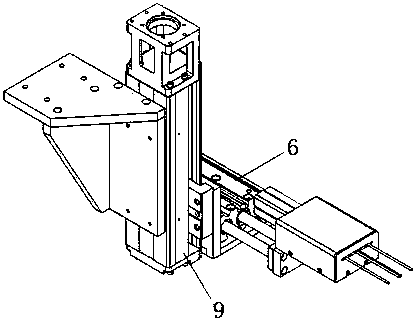

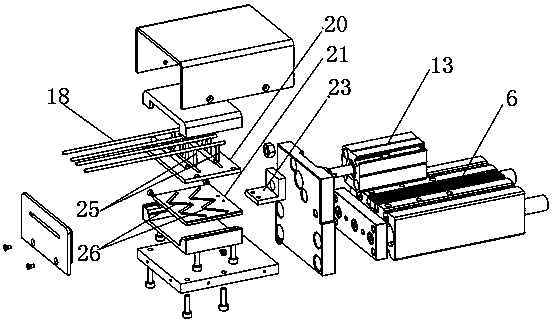

[0053] Such as Figure 1~24 As shown, the present invention proposes a specific embodiment of an intelligent assembly line for LED filament lamps, including a fixing device 1, a ball lamp carrier 5 for clamping and fixing LED filament lamps, a first fixing guide device b2, and filament leads The polarity testing equipment of the filament lead wire, the transparent casing device for the filament lead wire, the PCB wire threading device and the filament lead wire and the PCB welding device d4; the polarity test equipment of the filament lead wire includes a steering device 2 and a test device 3; the ball lamp The carrier 5 includes a PCB positioning and rotating mechanism 200 for clamping and positioning the PCB; the fixed wire device 1 includes two pairs of first fixed screw rods 18 that can move up and down and forward and bac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com