Method for additionally arranging upper wing on flat-plate wing of plate wing machine to improve rigidity and lift force of wing

A board-wing aircraft and wing technology, which is applied in the aviation field, can solve the problems of insufficient rigidity of the wing structure of the board-wing aircraft, divergence of chord blowing airflow, etc., and achieve the effect of eliminating mutual interference, improving structural rigidity and compacting the wing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

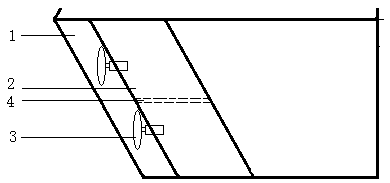

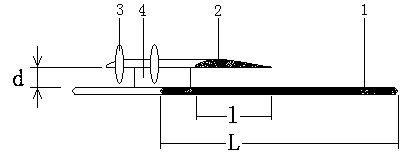

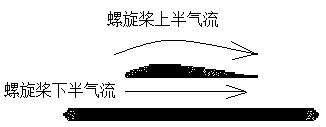

[0025] Embodiment 1: as Figure 1-3As shown, this method of adding an upper wing on the flat wing of a board-wing aircraft to improve wing rigidity and lift is for a small-scale board-wing aircraft that adopts a large-area continuous surface wide-chord wing and chord blowing to realize vertical take-off and landing and flight. , above the flat wing of the plate-wing aircraft (that is, the lower wing), an upper wing with a convex and flat airfoil is set, and the lower wing 1 is used as the main wing and the upper wing 2 is used as the aileron. On the two parallel surfaces of the upper and lower wings Two vertical spoilers 4 are arranged between them to enhance the rigidity, and a rectangular box is surrounded by two adjacent vertical spoilers, the upper surface of the lower wing and the lower surface of the upper wing, which enhances the structural rigidity of the wing and provides The installation of the drive device is convenient (provide a base for the drive device); arrange...

Embodiment 2

[0028] Example 2: see Figure 1-3 , this method of adding an upper wing on the flat wing of a board-wing aircraft to improve wing rigidity and lift is for a large-scale board-wing aircraft that uses a large-area continuous surface wide-chord wing and chord-wise air blowing to achieve vertical take-off and landing and flight. The top of the flat wing (lower wing) of the plate-wing aircraft is provided with an upper wing with a convex upper wing and a lower flat wing, which enhances the structural rigidity of the wing and facilitates the installation of the drive device (provides a base for the drive device to install), and the lower wing 1 is used as the main wing, and the upper wing 2 is used as the aileron. Four vertical spoilers 4 are arranged between the two parallel surfaces of the upper and lower wings to enhance the rigidity. Two adjacent vertical spoilers and the upper wing of the lower wing The surface and the lower surface of the upper wing form a rectangular box; 10 ...

Embodiment 3

[0031] Embodiment 3: see Figure 1-3 , see Figure 1-3 , the method of adding an upper wing on the flat wing of a board-wing aircraft to improve wing rigidity and lift is for a medium-sized board-wing aircraft that uses a large-area continuous surface wide-chord wing and chord-wise air blowing to achieve vertical take-off and landing and flight. The upper wing of the flat-winged wing (that is, the lower wing) is set on the upper side of the flat wing of the plate-wing aircraft. The lower wing 1 is used as the main wing and the upper wing 2 is used as the aileron. Between the two parallel surfaces of the upper and lower wings Three vertical spoilers 4 are set to enhance rigidity, and a rectangular box is surrounded by two adjacent vertical spoilers, the upper surface of the lower wing and the lower surface of the upper wing, which enhances the structural rigidity of the wing and provides The installation of the device is convenient (provide a base for the drive device); 6 smal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com