Concrete hanging board and manufacture method thereof

A production method and concrete technology, which is applied in the direction of construction, building structure, covering/lining, etc., can solve the problems of insufficient strength of concrete panels, poor quality of finished products, and poor functionality, so as to reduce manual workload, low production cost, Good economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The technical solution of the present invention will be clearly and completely described below in conjunction with the accompanying drawings in this embodiment.

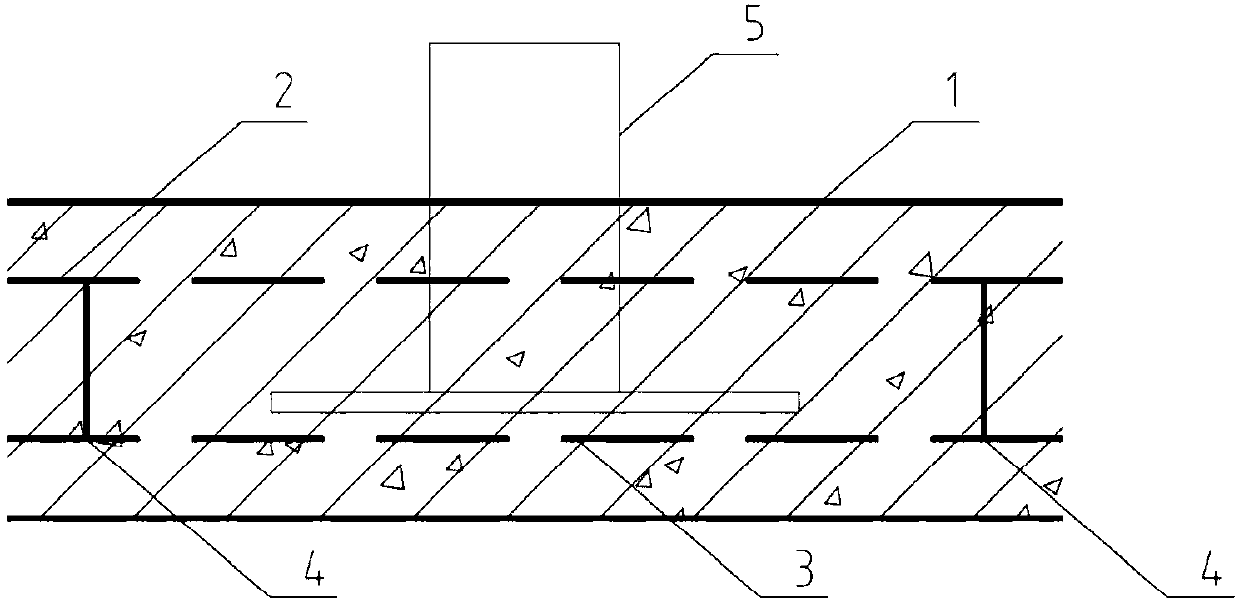

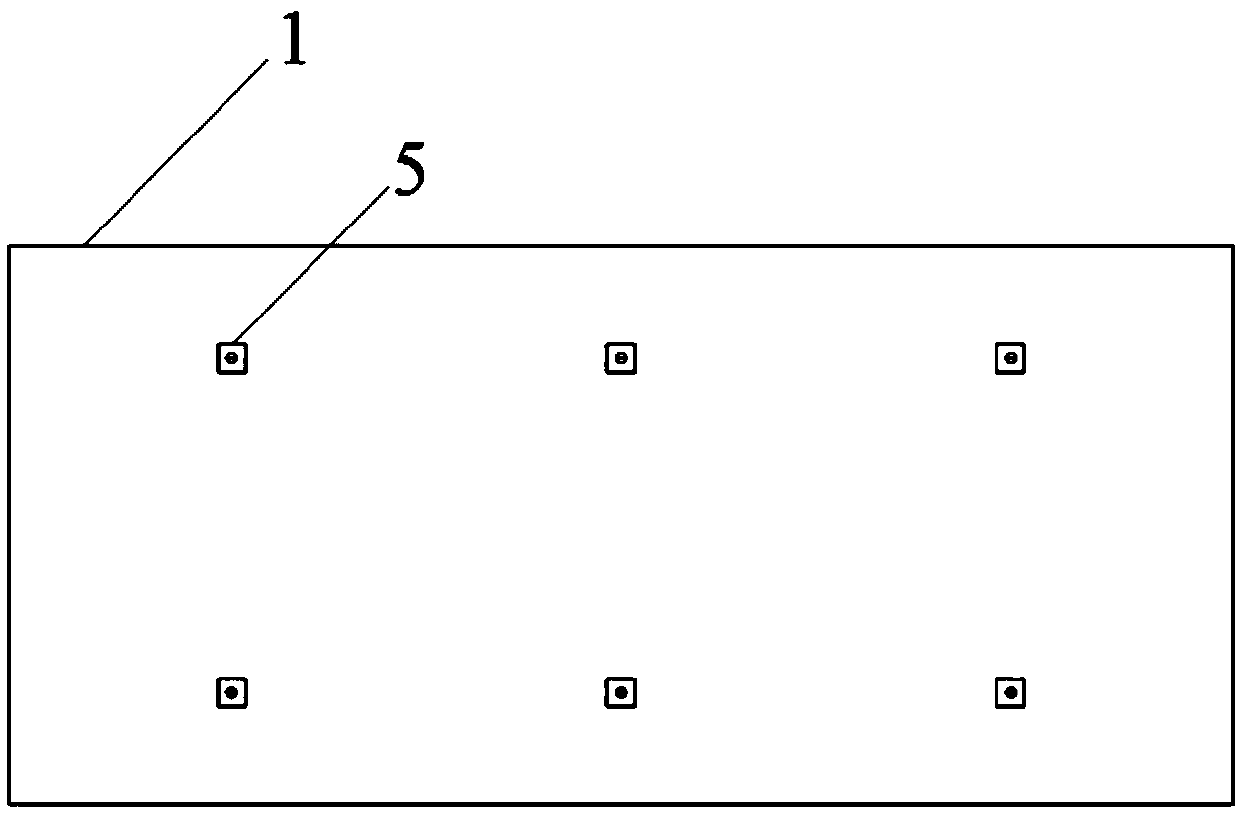

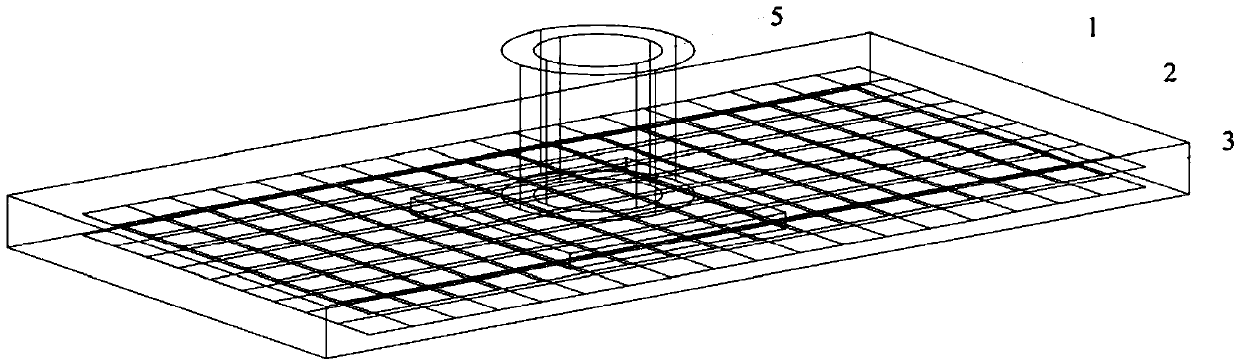

[0040] like figure 1 As shown, a concrete hanging slab of this embodiment includes a slab body 1 , two grid layers, positioning parts 4 and embedded parts 5 . Two grid layers are arranged inside the board body 1 .

[0041] The panel body 1 is poured from high-performance concrete, such as UHPC material or RPC material, with a thickness of 20-50mm.

[0042] The two-layer grid layer is composed of an upper grid layer 2 and a lower grid layer 3 , and the two-layer grid is arranged parallel to the surface of the plate body 1 . The grid layer can choose at least one of basalt fiber grid, carbon fiber grid, and steel wire grid; The distance between the lower surface is 3-20mm.

[0043] The positioning piece 4 longitudinally connects the upper grid 2 and the lower grid 3 to fix the distance between adjacent grids...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com