Ion fan with self-cleaning function

An ion fan, self-cleaning technology, applied in cleaning methods and utensils, cleaning methods using gas flow, components of pumping devices for elastic fluids, etc. Noise and other problems, to achieve the effect of easy miniaturization, low energy consumption, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

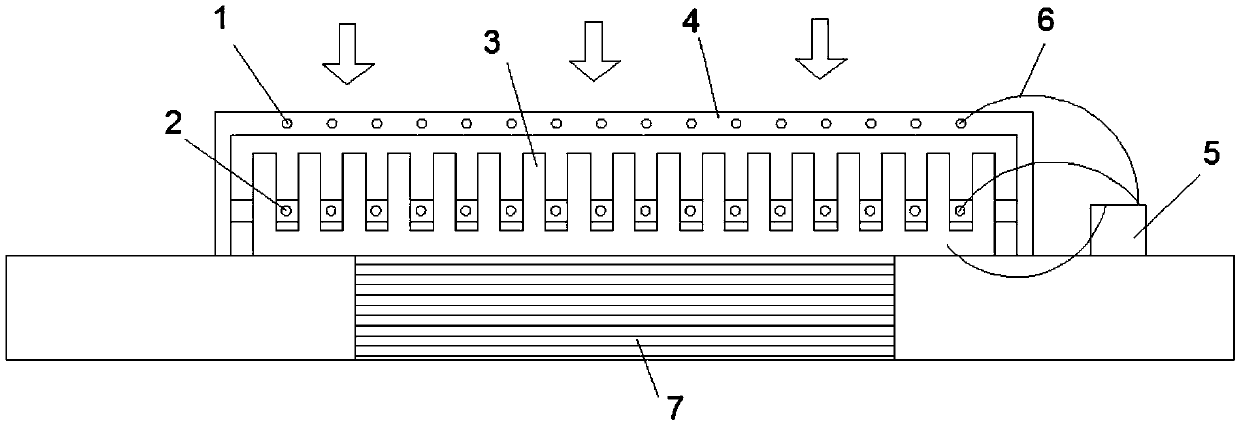

[0029] Such as figure 1 As shown, the heat dissipation system of this embodiment is composed of a heating element 7 and an ion fan with a self-cleaning function. The ion fan with self-cleaning function mainly includes: a discharge electrode 1 for heat dissipation, a discharge electrode 2 for self-cleaning, a collector electrode 3, an electrode frame 4, a driving power supply 5 and a wire 6. Such as figure 2 As shown, the wire 6 includes a cooling circuit switch 601 and a self-cleaning circuit switch 602 .

[0030] In this embodiment, the flat surface of the collecting electrode 3 is close to the heating element, and the opposite surface is a long straight fin structure, and ion wind channels are formed between adjacent fins. The discharge electrode 1 for heat dissipation is a wire electrode, using stainless steel wire, each wire electrode is located above the center line of the two fins, fixed on the electrode frame 4, and connected to the positive pole of the driving power...

Embodiment 2

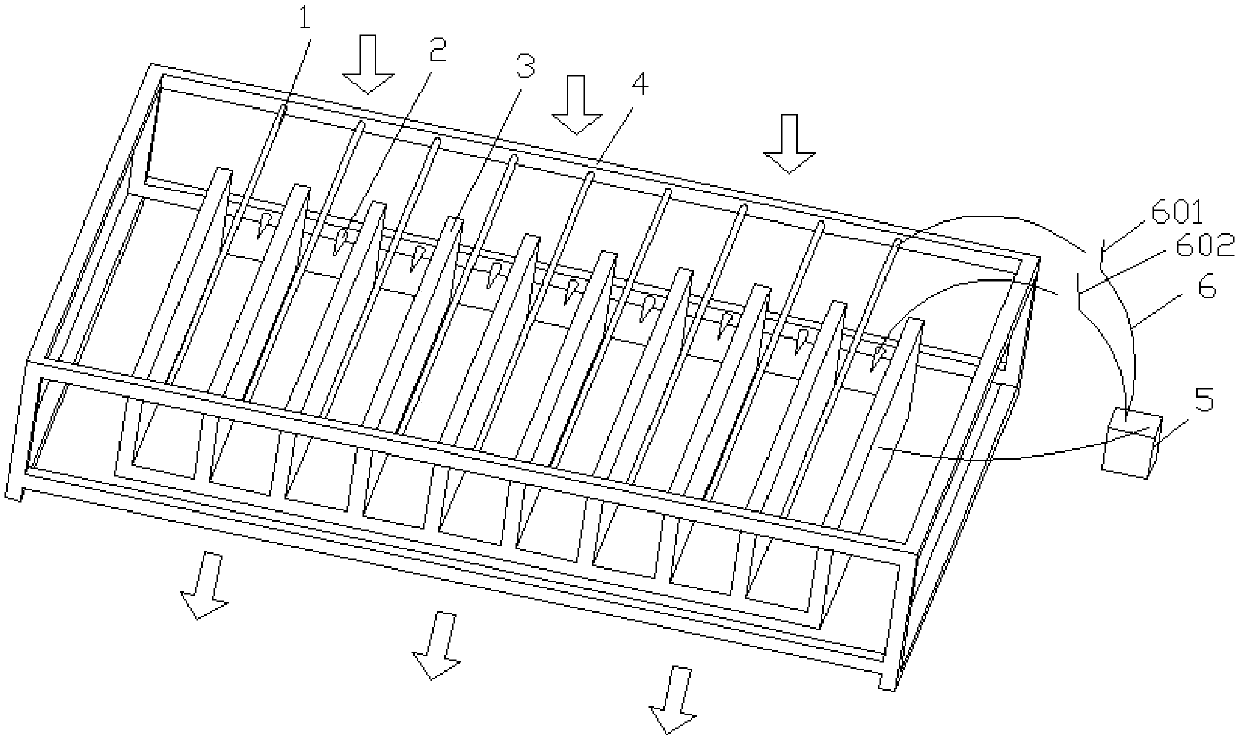

[0035] The cooling system of this embodiment is the same as that of Embodiment 1 except for the structure of the ion fan with self-cleaning function.

[0036] Such as image 3 As shown, in the ion fan with self-cleaning function in this embodiment, the flat surface of the collector electrode 3 is in contact with the heating element, and the opposite side is composed of fin columns arranged at intervals along the longitudinal direction, and the fin columns are formed in a horizontal direction. ionic wind channel. The discharge electrode 1 for heat dissipation is a linear electrode, made of stainless steel wire, located above the ion wind channel, fixed on the electrode frame 4, and connected to the positive pole of the driving power supply 5 through a lead 6. The self-cleaning discharge electrode 2 is a needle-shaped electrode, near the root of the collector electrode 3 fins, on the electrode frame 4 on the side of the collector electrode 3 ion wind passage, the needle is faci...

Embodiment 3

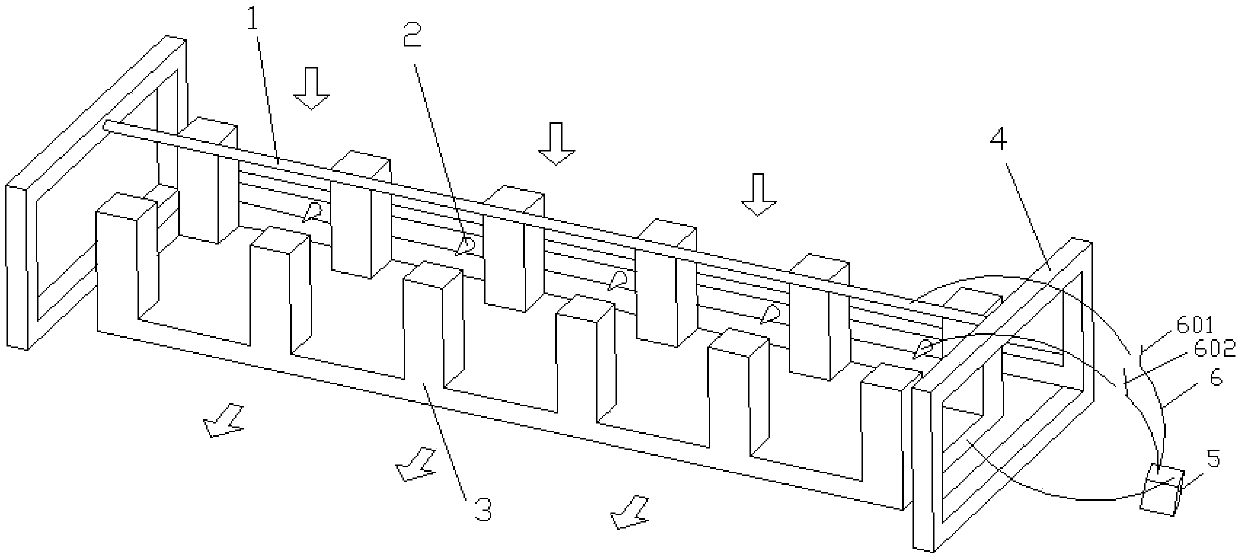

[0040] The cooling system of this embodiment is the same as that of Embodiment 1 except for the structure of the ion fan with self-cleaning function.

[0041] Such as Figure 4As shown, the flat surface of the collector electrode 3 in this embodiment is in contact with the heating element, and the opposite surface is composed of fin columns arranged at intervals in the longitudinal direction, and ion wind channels extending in the transverse direction are formed between the fin columns. The discharge electrode 1 for heat dissipation is a needle-shaped electrode, located above the ion wind channel, fixed on the electrode frame 4, the needle points to the surface of the collector electrode 3, and is connected to the positive pole of the driving power supply 5 through a wire 6. The self-cleaning discharge electrode 2 is also a needle-shaped electrode, which is located near the root of the collector electrode 3 fins, on the electrode frame 4 on one side of the collector electrode ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com