Right-angle output steel ball speed reducer

A reducer and steel ball technology, applied in mechanical equipment, transmission parts, friction transmission and other directions, can solve the problems of low service life, low transmission efficiency and complex manufacturing process of the soft tooth surface reducer, and achieve the purpose of solving the problems of soft tooth surface reducer. Low surface strength, short life, improved bearing capacity and service life, and the effect of solving the difficulty of adjusting axial clearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

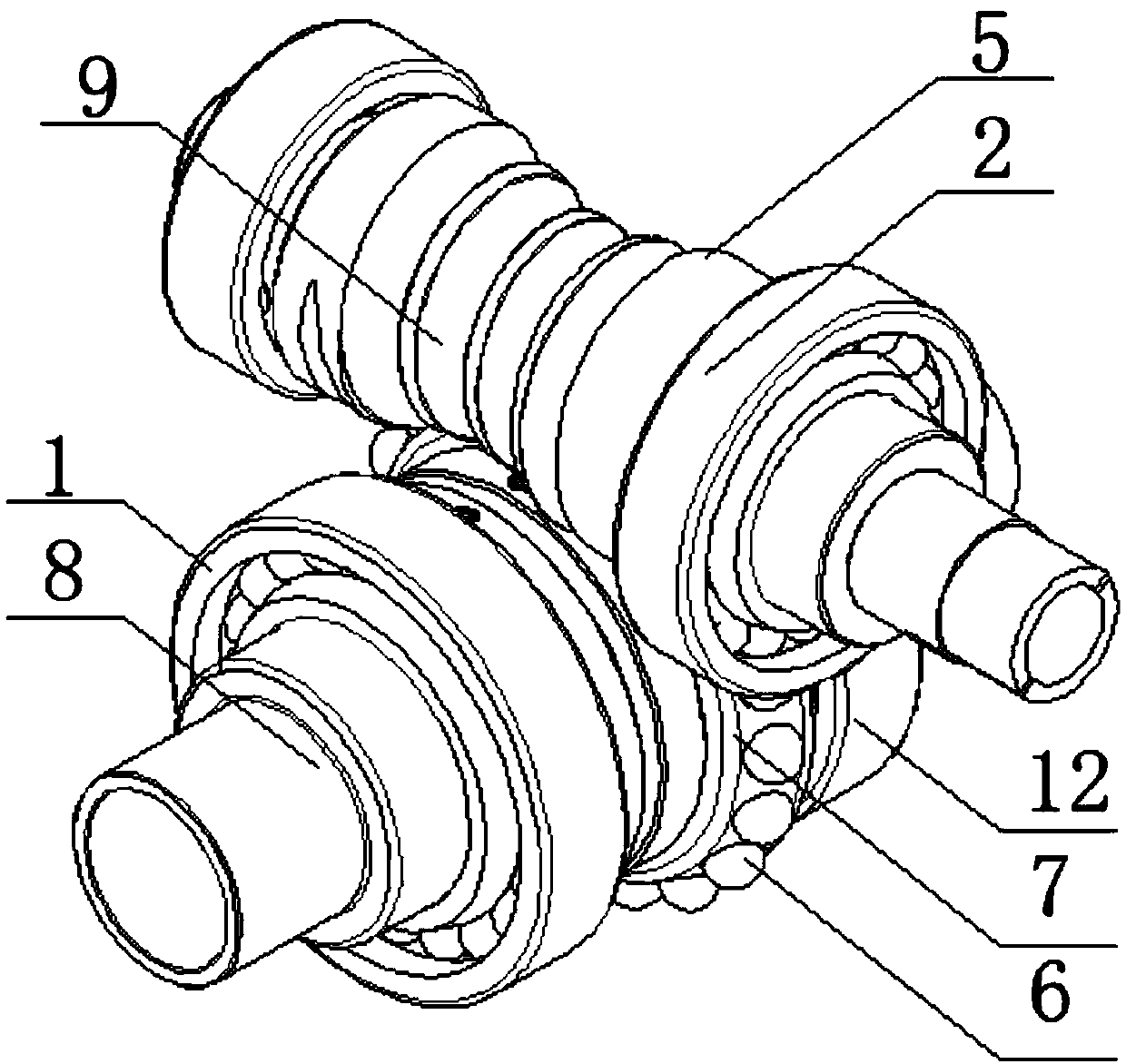

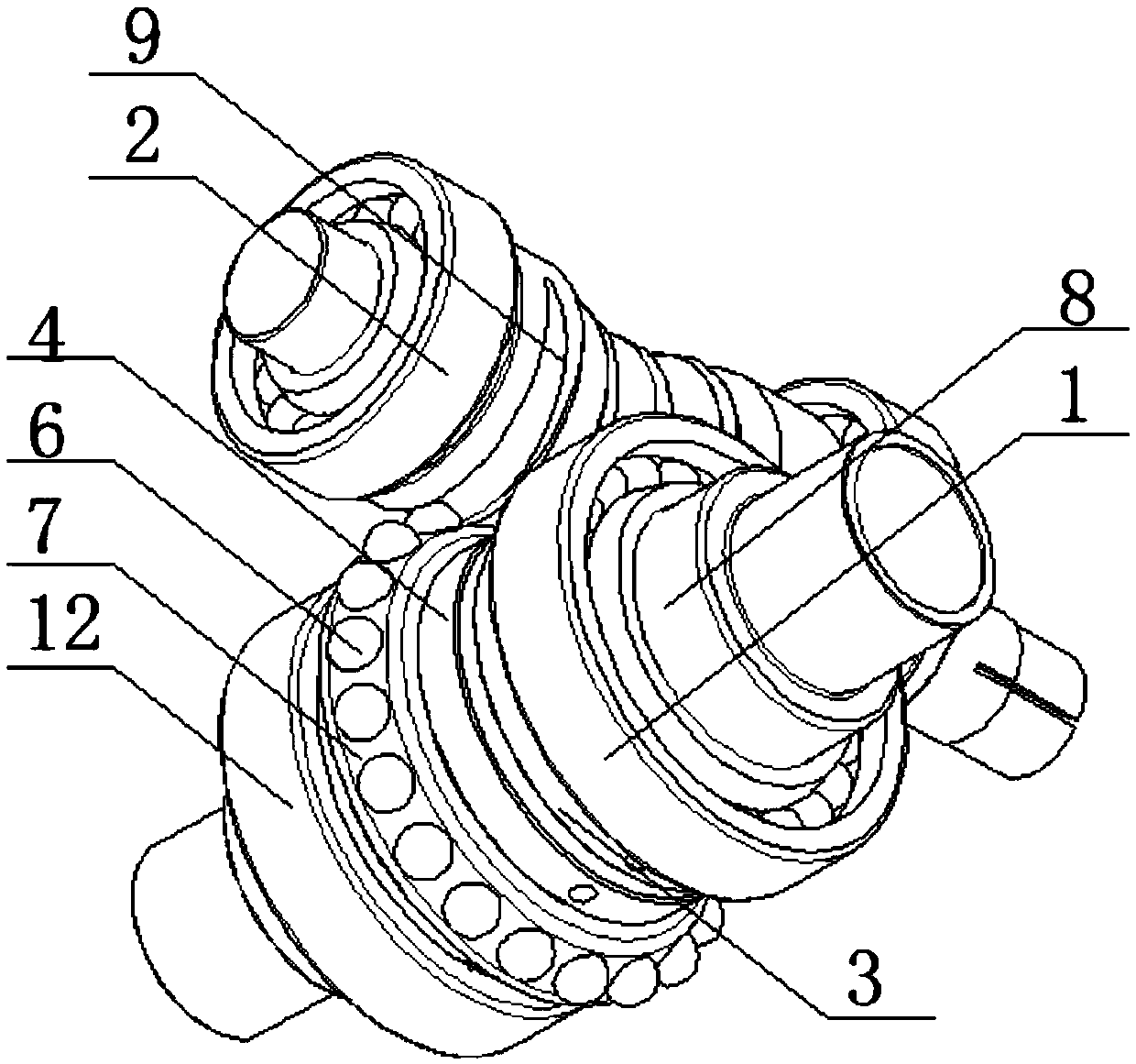

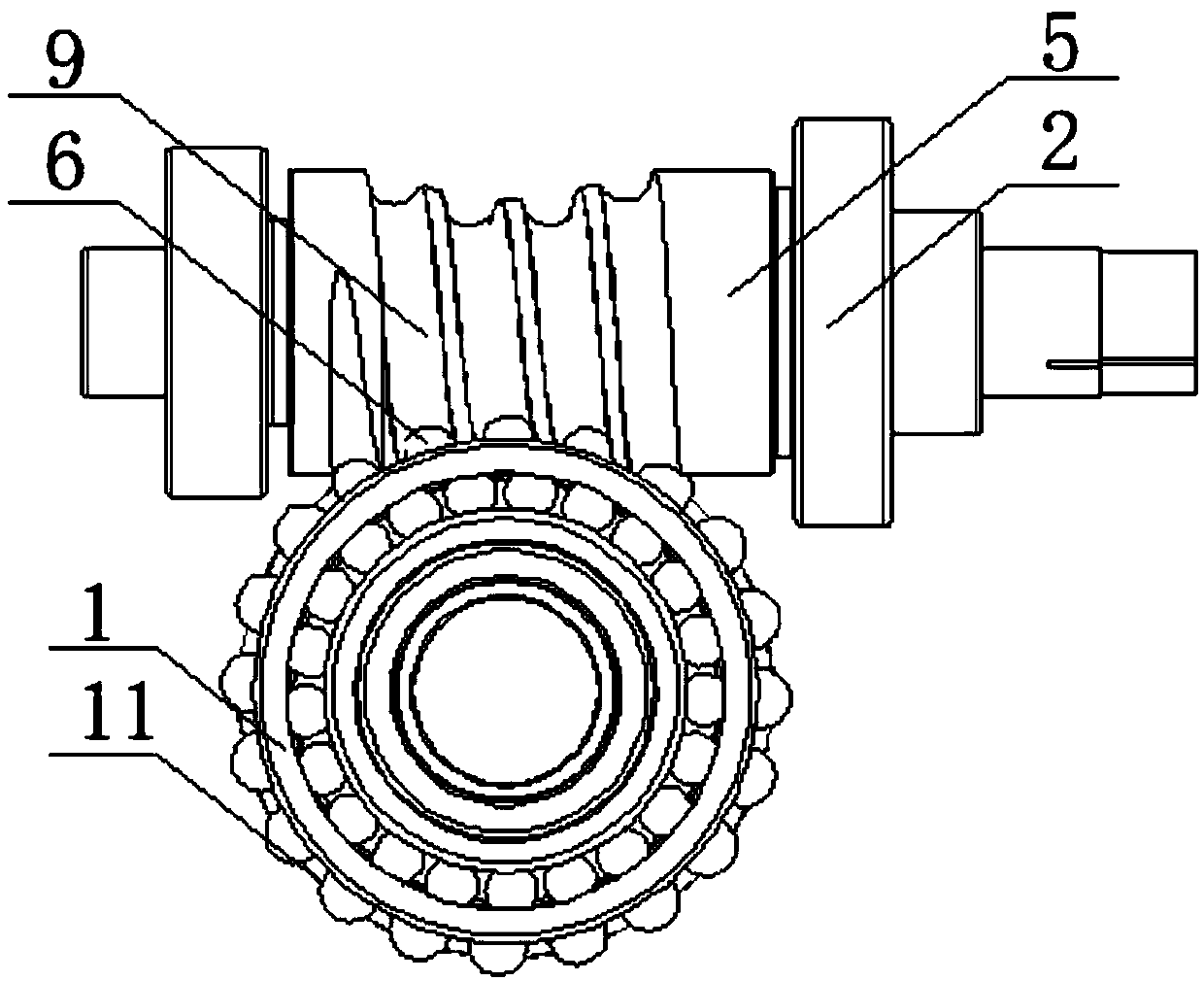

[0031] refer to Figure 1-6 , a right-angle output steel ball reducer, including an input shaft 5 and an output shaft 8, input shaft support bearings 2 are installed at both ends of the input shaft 5, the input shaft support bearings 2 improve the output of the input shaft 5, and the input shaft 5 A plurality of steel ball slides 9 are arranged at equal intervals in the middle, and the steel ball slides 9 are processed in a special way, and the steel ball slides 9 are located between the two input shaft support bearings 2, and the rotation of the input shaft 5 will make the steel ball slides 9 rotation, the two ends of the output shaft 8 are respectively fixed with t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com