Whole equipment control device, rolling mill control device, control method, and storage medium

A technology of a complete set of equipment and control methods, which is applied in the field of storage media with programs, can solve problems such as difficult to output control accuracy, find control rules, and difficult to modify control rules, so as to cope with changes over the years, improve control accuracy, and shorten start-up The effect of the period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

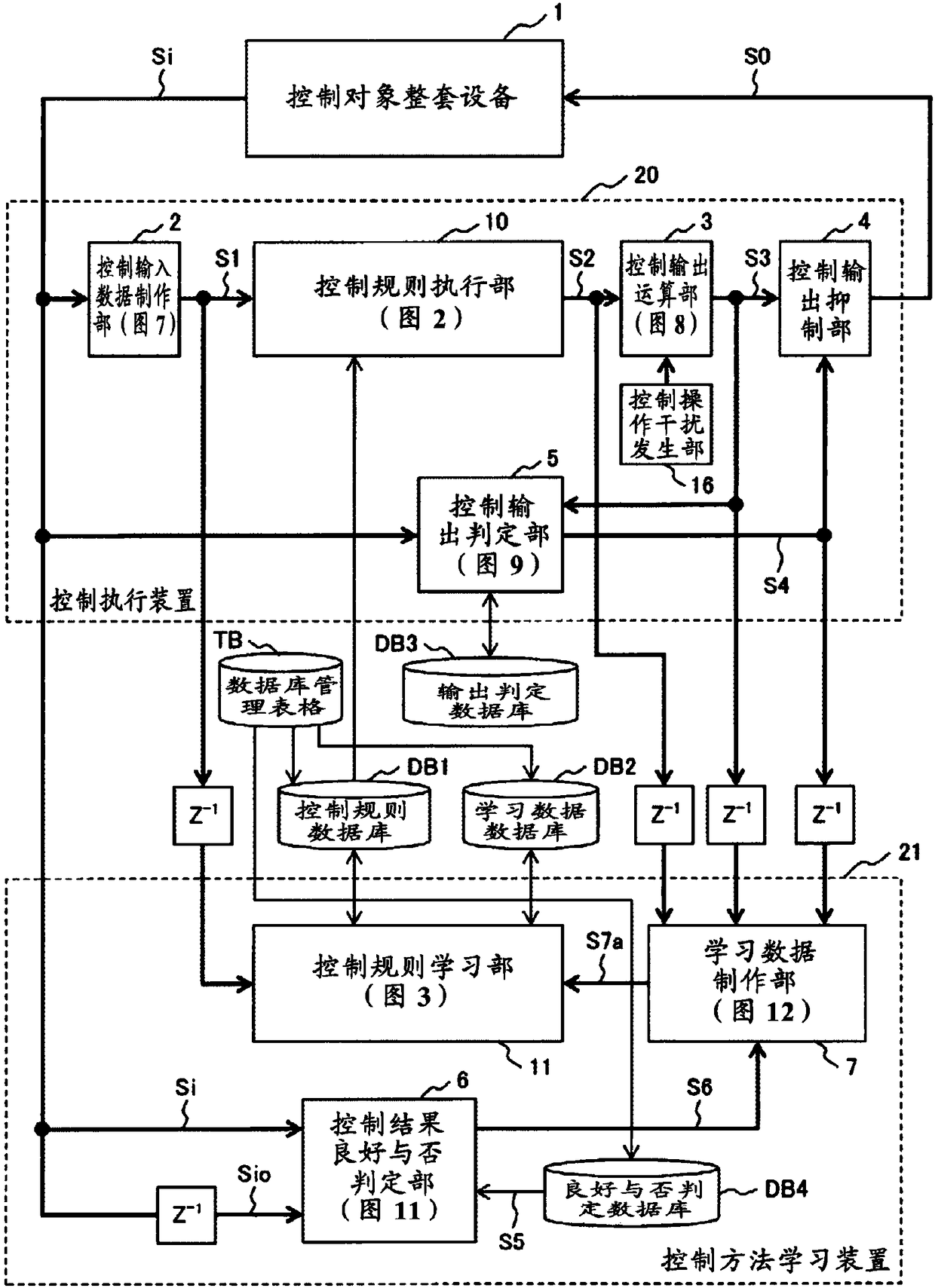

[0071] figure 1 The outline of the plant control device according to the embodiment of the present invention is shown. figure 1 The whole set of equipment control device includes: the whole set of equipment 1 of the control object; the control execution device 20, which inputs the actual data Si from the whole set of equipment 1 of the control object, according to the following Figure 6 The control operation amount output SO determined by the exemplified control rule (neural network) is provided to the controlled plant 1 for control; the control method learning device 21 inputs actual data Si from the controlled plant 1 to perform learning, and the learned The output control rules are reflected in the control rules in the control execution device 20; a plurality of databases DB (DB1 to DB3); and the management table TB of the database DB.

[0072] The control execution device 20 is composed of a control input data creation unit 2, a control rule execution unit 10, a contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com