Double-telescopic self-balancing tower crane for cargo ship

A self-balancing and telescopic technology, applied in cranes and other directions, can solve the problems of single function, poor load capacity, inflexibility and convenience of knuckle-arm cranes and straight-arm cranes, so as to solve the complex lifting operation and eliminate dependence. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

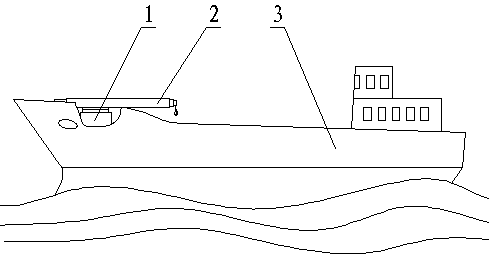

[0021] As shown in the figure, the double-telescopic self-balancing tower crane is arranged on the cargo ship 3, and the telescopic base assembly 1 and the telescopic self-balancing boom assembly 2 in the double-telescopic self-balancing tower crane are retracted and docked at ordinary times.

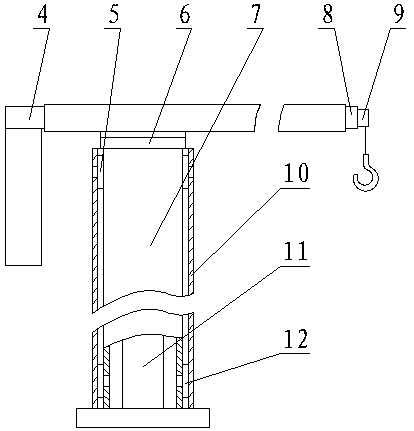

[0022] The telescopic base assembly 1 in the double telescopic self-balancing tower crane is installed on the cargo ship 3, the telescopic base assembly 1 is provided with a rotating assembly 6, and the telescopic self-balancing boom assembly 2 is placed on the rotating assembly 6;

[0023] The upper part of the outer support 10 in the telescopic base assembly 1 is provided with an upper pulley device 5 around, and the lower part of the inner support 7 is provided with a lower pulley device 12, and the inner support 7 is nested in the outer support 10; the inner support is driven by the lifting assembly 11 7. Make lifting movement, like this, telescopic base assembly (1) just can be lift...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com