Full-automatic filling device

A filling device, fully automatic technology, applied in the field of fully automatic filling devices, can solve problems such as unsatisfactory, long standby time, uneven orange juice cell content, etc., to ensure stability and controllability, ensure quality, and avoid waste Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

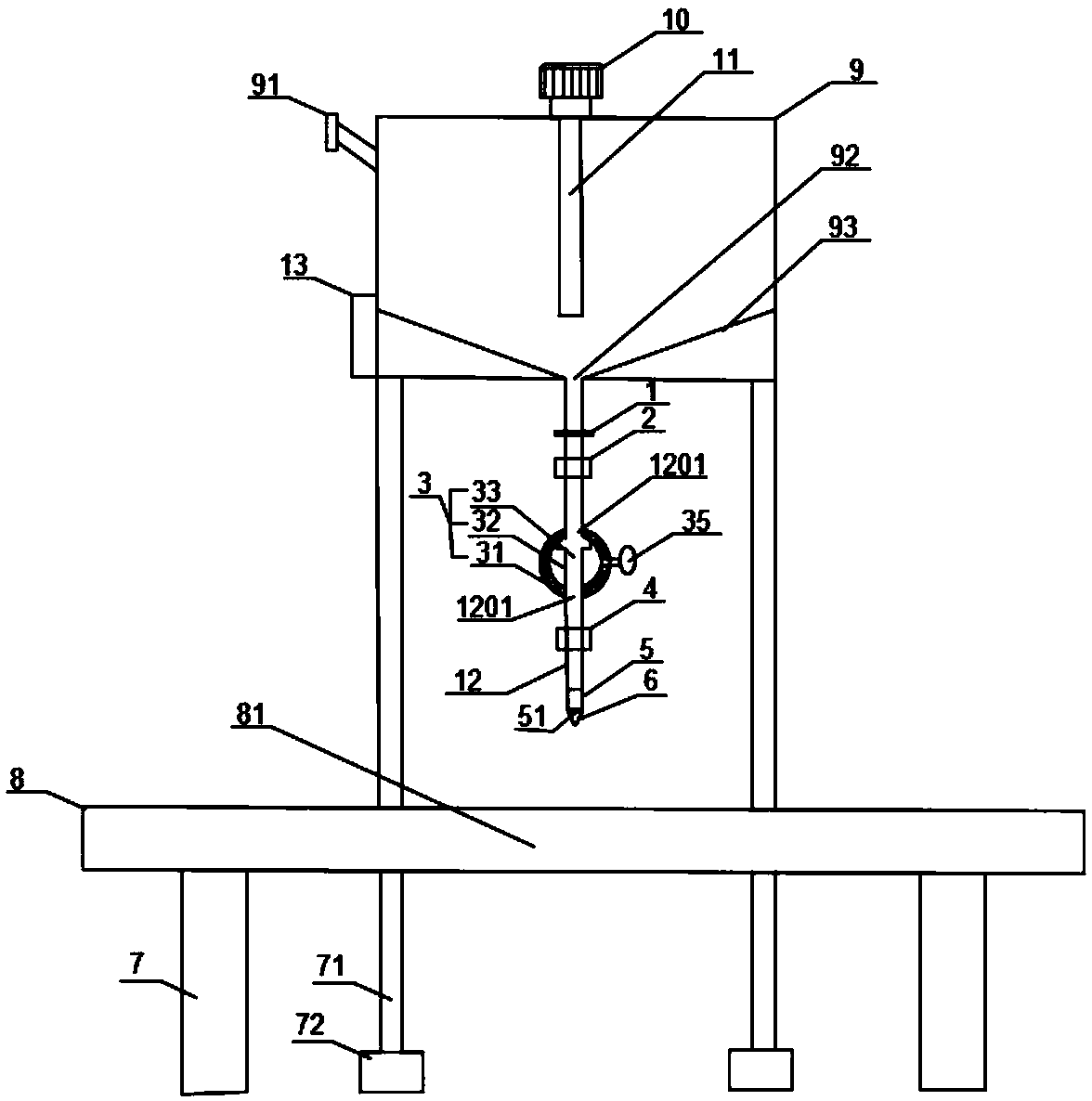

[0026] A kind of automatic filling device described in this embodiment, combined with figure 1 Describe, comprise frame 7, bottle conveyor belt 8, material tank 9, bottle conveyor belt 8 is installed on the frame 7, filling area 81 is set on the bottle body conveyor belt 8, filling area 81 and material tank 9 The discharge port 92 that bottom is provided with is arranged correspondingly; The top center of feed tank 9 is provided with rotating motor 10, and the output shaft of rotating motor 10 is connected with stirring rod 11, and the lower end of stirring rod 11 stretches into feed tank 9 inside; A pH sensor, a concentration sensor and a temperature sensor are set, and a downwardly inclined V-shaped base plate 93 is arranged at the bottom of the material tank 9, and a discharge port 92 is provided at the lowest point of the V-shaped base plate 93; One end is connected, and the other end of the filling pipe 12 is connected with the filling port 6. The filling pipe 12 is provi...

Embodiment 2

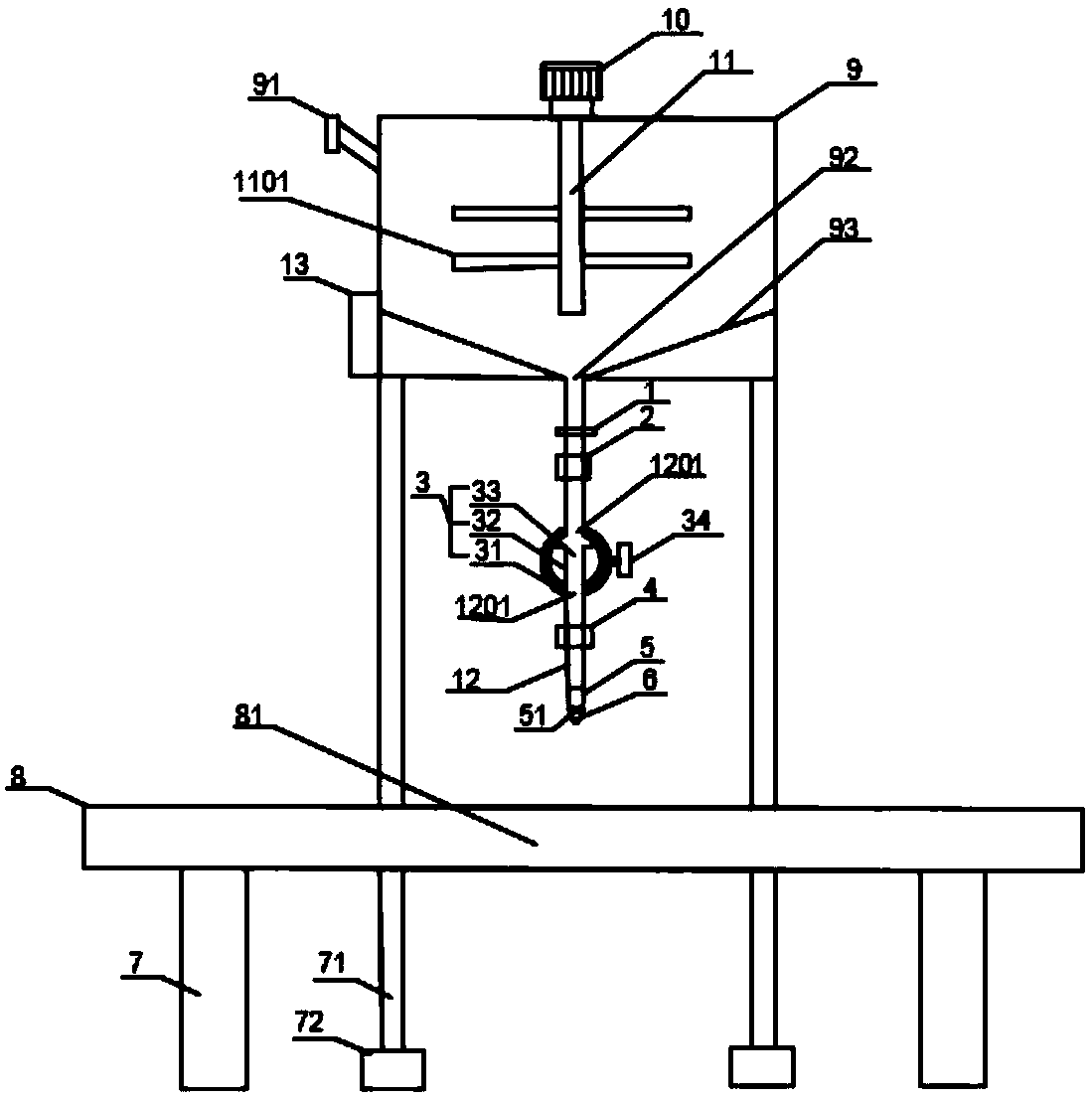

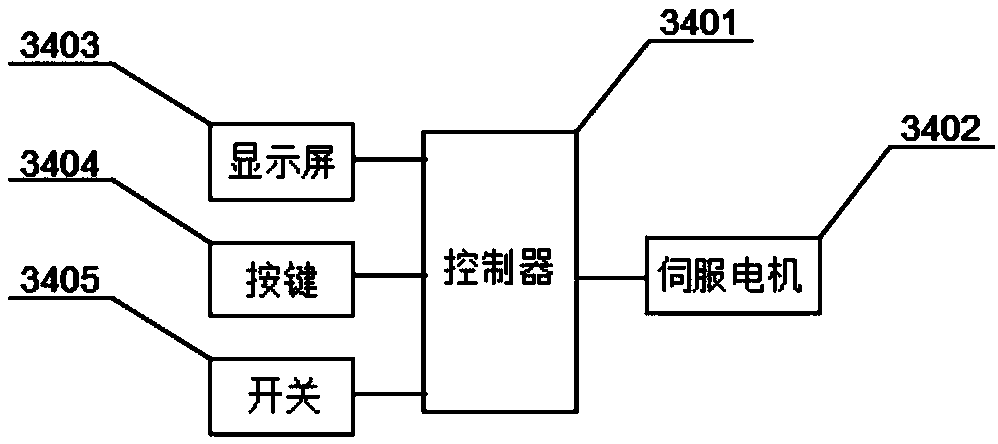

[0031] A kind of fully automatic filling device described in this embodiment is basically the same as Embodiment 1, and the difference is combined Figure 2 ~ Figure 4 To illustrate, it also includes: the valve cover 31 is provided with a control box 34, the control box 34 is provided with a controller 3401, a servo motor 3402, and the surface of the control box 34 is provided with a display screen 3403, buttons 3404 and switches 3405; Servomotor 3402, display screen 3403, button 3404, switch 3405 are electrically connected; the output shaft of servomotor 3402 is connected with one end of spool 32; material tank 9 bottom is provided with fixed support 71, and support 71 bottom is provided with elevating mechanism 72, and elevating mechanism 72 It is a lifting cylinder, and the top of the lifting cylinder is fixed on the bottom of the bracket 71; the stirring rod 11 is uniformly provided with horizontal stirring blades 1101 along the circumferential direction.

[0032] The spec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com