Preparation method of a high temperature resistant gradient fiber composite airgel thermal insulation material

A fiber composite, thermal insulation material technology, applied in chemical instruments and methods, ceramic products, other household appliances, etc., can solve the problems of difficult large-scale application, difficult machining, molding, low aerogel strength, etc. To achieve the effect of improving heat insulation effect, improving temperature resistance and increasing operating temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

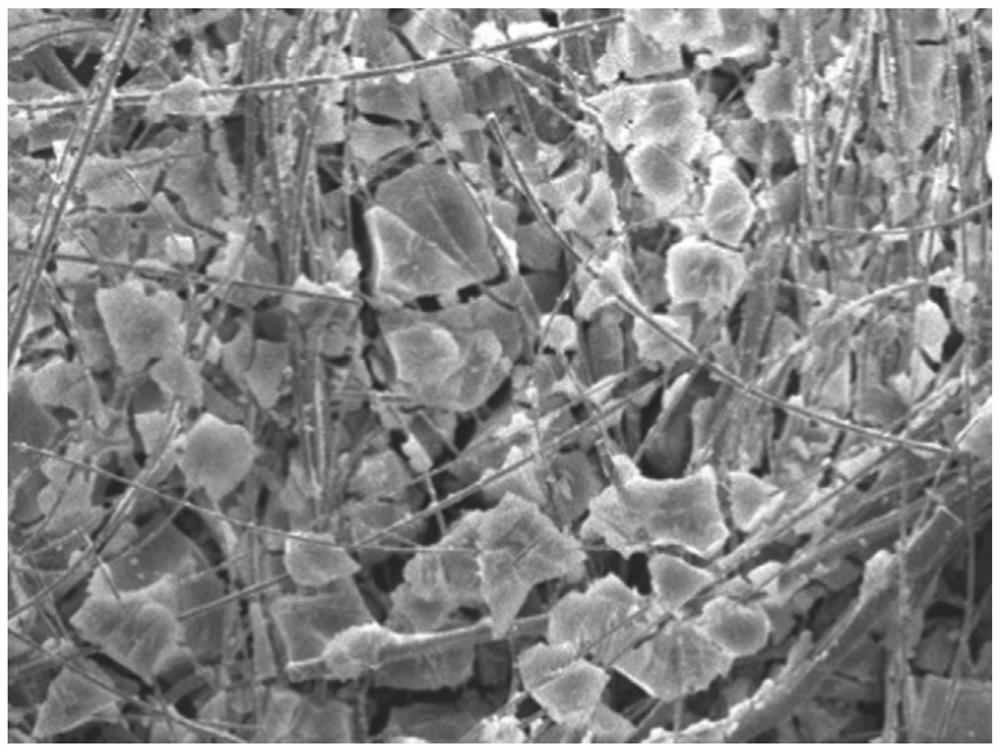

Image

Examples

example 1

[0026] Silica sol (SiO 2 The particle size is 10nm, the content is 20wt%), absolute ethanol, and deionized water are mixed uniformly at a volume ratio of 1:0.5:0.1 to form a solution, and mixed and stirred at 45°C for 30min to obtain clear SiO 2 For the sol solution, continue to add hydrochloric acid to adjust the pH value of the solution to 4, then impregnate the sol solution into the glass fiber felt in the mold, seal the film, and place it in a vacuum oven at 50°C for 3 hours to obtain a glass fiber composite SiO 2 Wet gel, recorded as fiber composite wet gel A, takes out the mold, and places aluminum silicate fibers on its upper surface; continue to add silica sol (SiO 2 Particle size is 10nm, content is 20wt%), alumina sol (Al 2 o 3Particle size is 10nm, content is 20wt%), absolute ethanol, deionized water according to the volume ratio according to the volume ratio 1:0.2:0.5:0.2 mix uniformly and make the solution, mix and stir at 45 ℃ for 30min, continue to add hydroch...

example 2

[0028] Silica sol (SiO 2 The particle size is 20nm, the content is 45wt%), absolute ethanol, and deionized water are mixed uniformly in a volume ratio of 1:2:1 to form a solution, and mixed and stirred at 50°C for 60min to obtain a clear SiO 2 For the sol solution, continue to add hydrochloric acid to adjust the pH value of the solution to 6, then impregnate the sol solution into the glass fiber felt in the mold, seal the film, and place it in a vacuum oven at 60°C for 6 hours to obtain a glass fiber composite SiO 2 Wet gel, recorded as fiber composite wet gel A, takes out the mold, and places aluminum silicate fibers on its upper surface; continue to add silica sol (SiO 2 Particle size is 20nm, content is 45wt%), alumina sol (Al 2 o 3 The particle size is 20nm, the content is 30wt%), absolute ethanol, and deionized water are mixed uniformly in a volume ratio of 1:5:3:2 to form a solution, mixed and stirred at 50°C for 60min, and continue to add hydrochloric acid to adjust ...

example 3

[0030] Silica sol (SiO 2 The particle size is 15nm, the content is 30wt%), absolute ethanol, and deionized water are mixed uniformly at a volume ratio of 1:1:0.5 to form a solution, and mixed and stirred at 45°C for 50min to obtain clear SiO 2 For the sol solution, continue to add nitric acid to adjust the pH value of the solution to 5, then impregnate the sol solution into the glass fiber felt in the mold, seal the film, and place it in a vacuum oven at 55°C for 4 hours to obtain a glass fiber composite SiO 2 Wet gel, recorded as fiber composite wet gel A, takes out the mold, and places aluminum silicate fiber on its upper surface; then silica sol (SiO 2 Particle size is 15nm, content is 30wt%), alumina sol (Al 2 o 3 Particle size is 15nm, content is 25wt%), absolute ethanol, deionized water by volume ratio 1:1:1:1 by volume and mix uniformly to make solution, mix and stir at 50 ℃ for 60min, continue to add nitric acid, adjust The pH value of the solution is 5, the SiO 2 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com