Smart sizing machine

A sizing machine, intelligent technology, applied in textile processing machine accessories, liquid/gas/vapor yarn/filament processing, textile and papermaking, etc., can solve the impact of sizing operations, prone to misjudgment or delay, reduce production efficiency issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The technical solutions and beneficial effects of the present invention will be clearer and more definite by further describing the specific embodiments of the present invention in conjunction with the accompanying drawings.

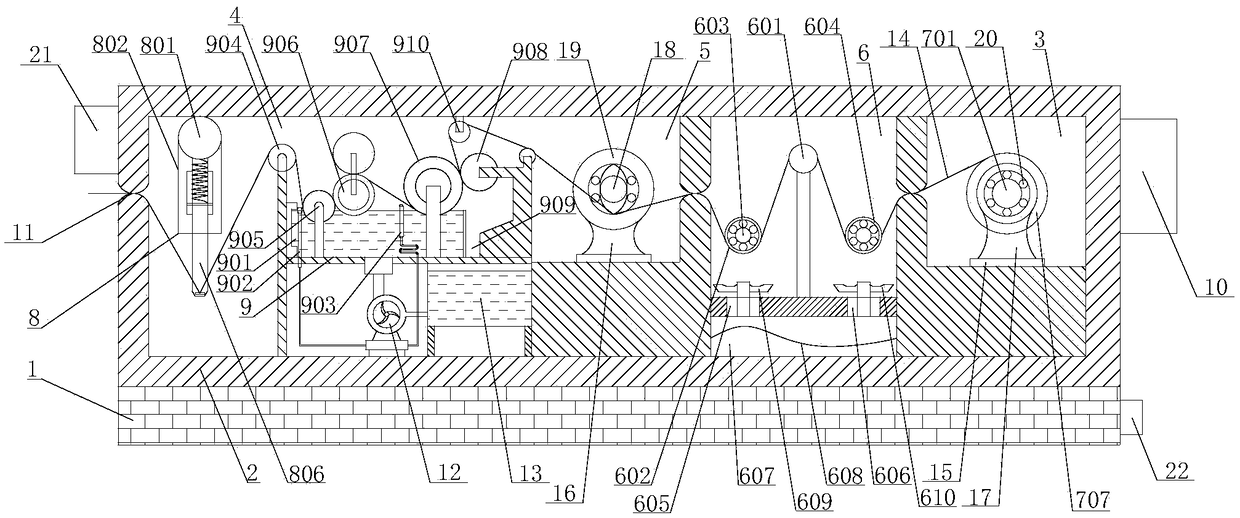

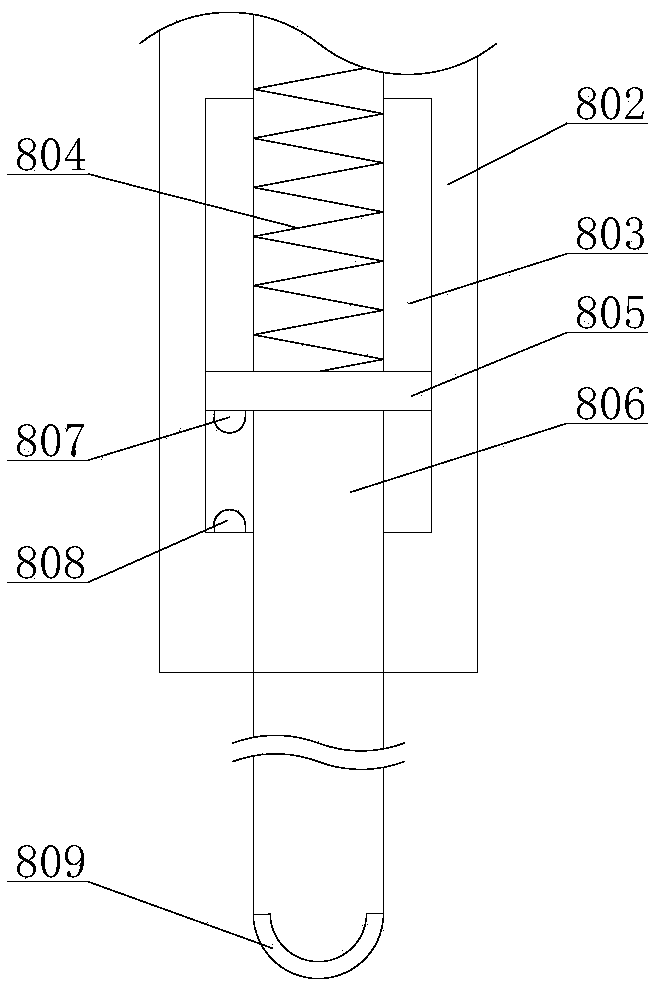

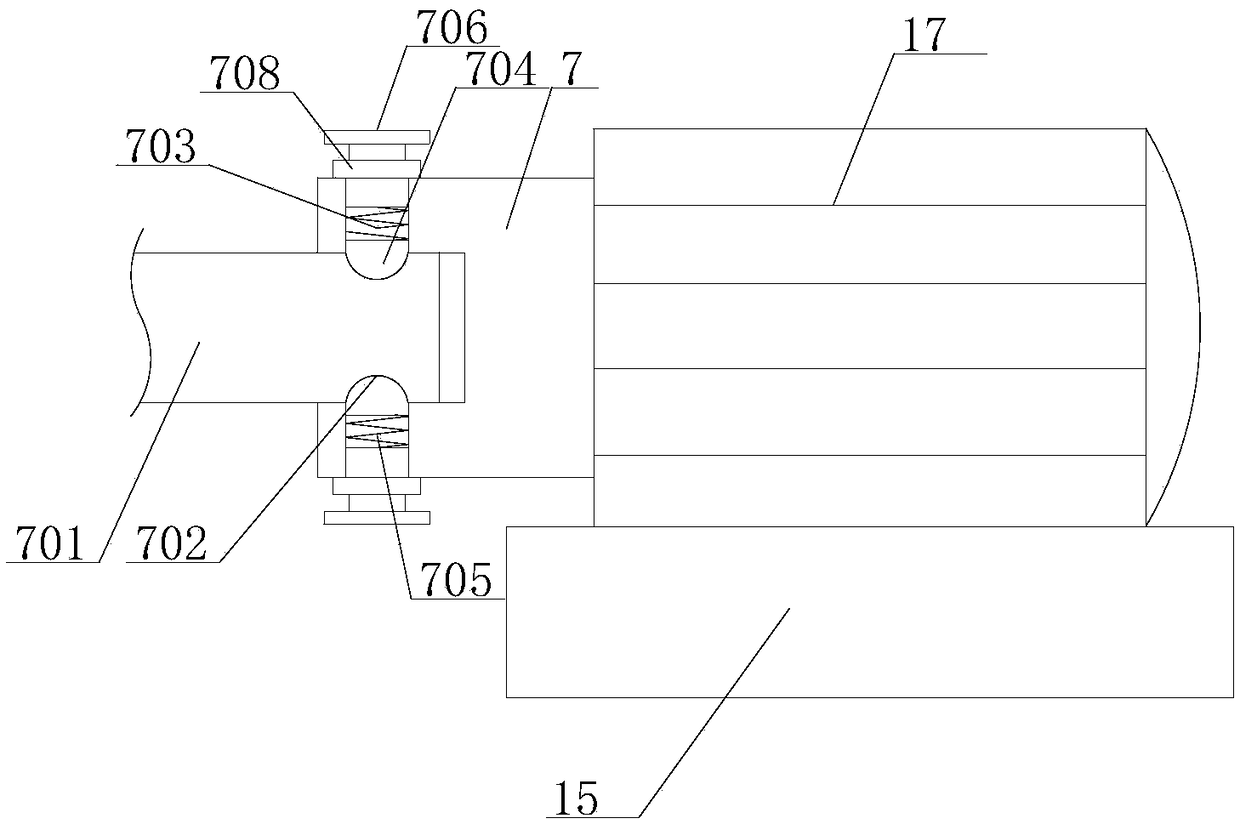

[0027] Such as Figure 1-3As shown, an intelligent sizing machine includes a base 1, the upper surface of the base 1 is fixedly connected with a sizing box 2, and a control cabinet 10 is installed on one side of the sizing box 2, and the sizing box The inside of the body 2 is respectively provided with a sizing mechanism 4, a fluffing mechanism 5, a drying mechanism 6 and a winding mechanism 3 through a partition, and the left inner walls of the sizing mechanism 4, the drying mechanism 6 and the winding mechanism 7 are all provided with There is a yarn threading port 11, and a yarn breaking device 8 is also arranged between the sizing mechanism 4 and the threading port 11. The sizing mechanism 4 includes an upper sizing tank 9 and a lower sizing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com