Vehicle road simulation system

A road simulation and vehicle technology, applied in the field of vehicle road simulation system, can solve the problems of inability to assess the durability of the powertrain suspension system, the subframe and the body structure, the complex structure of the simulation test system, and the poor simulation accuracy. Achieve the effect of improving versatility and reliability, improving simulation accuracy, and fast response.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

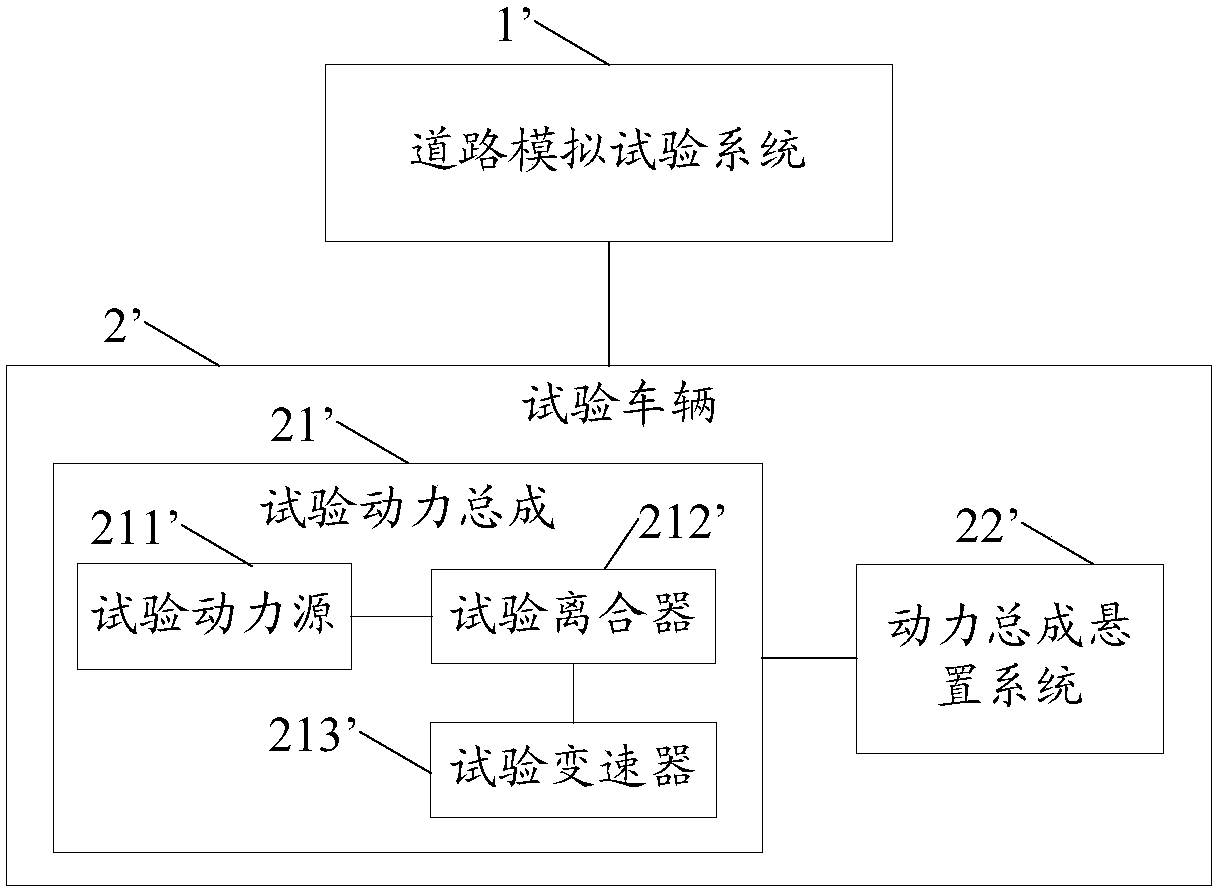

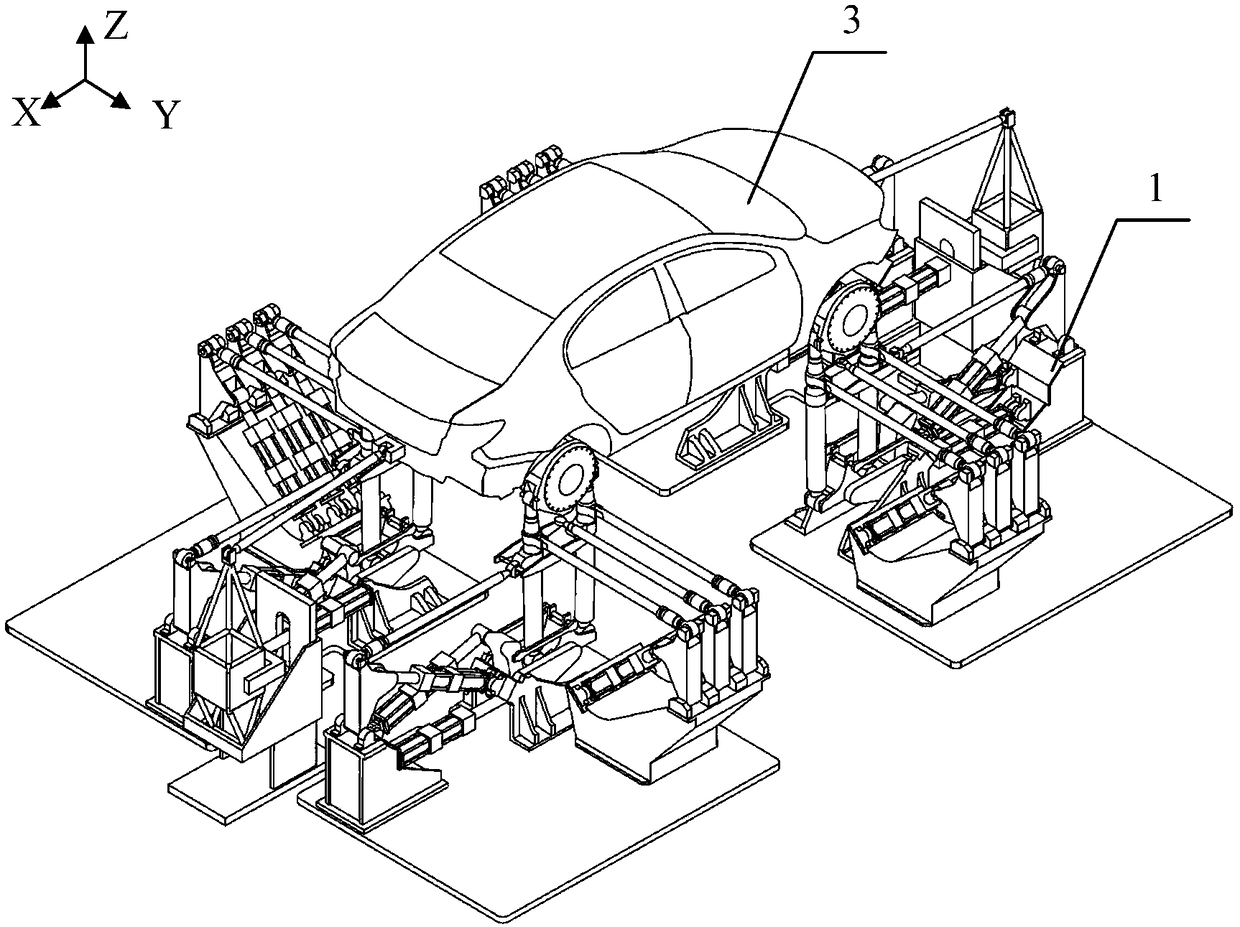

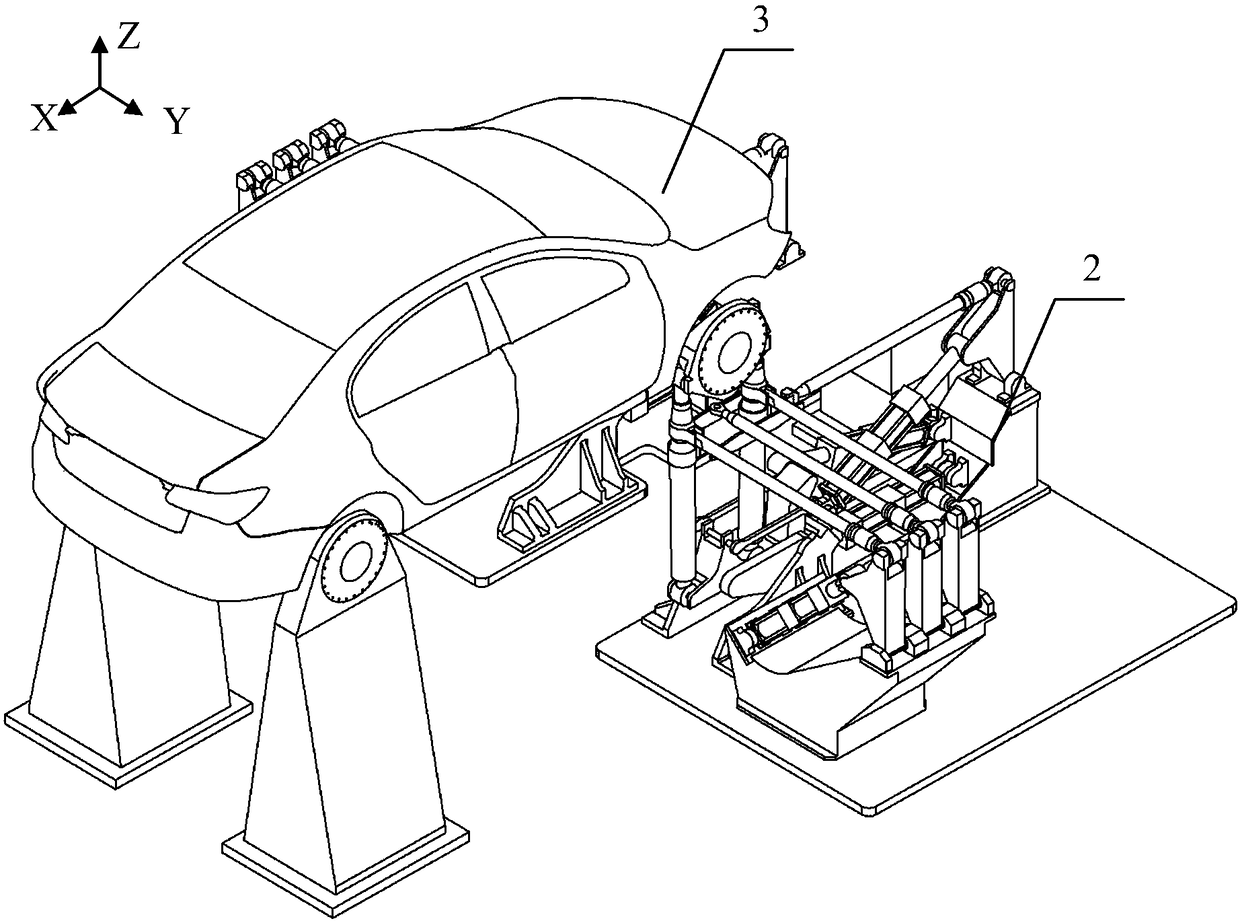

[0028] As mentioned above, the current vehicle road simulation system either has the problem of complex structure or the problem of poor simulation accuracy.

[0029] In order to solve the above problems, the vehicle road simulation system of the embodiment of the present invention sets the body structure and chassis system of the test vehicle to be the same as the actual vehicle, the output shaft of the test power source and the casing of the test power source are relatively stationary, and the test The housing of the power source does not output power, and when the control test clutch is closed, it outputs the road that can simulate the driving of the test vehicle and the output of the torque of the test power source to the power assembly through the movement of the road simulation test system. The force generated by the suspension system can simulate the force of the powertrain suspension system on the actual vehicle, avoiding the direct loading of the powertrain suspension ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com