Spacing device and spacing method

A separation device and separation method technology, which is applied in the manufacture of electrical components, circuits, semiconductors/solid devices, etc., can solve the problem of narrowing the distance between adherends and achieve the effect of expanding the distance between them

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

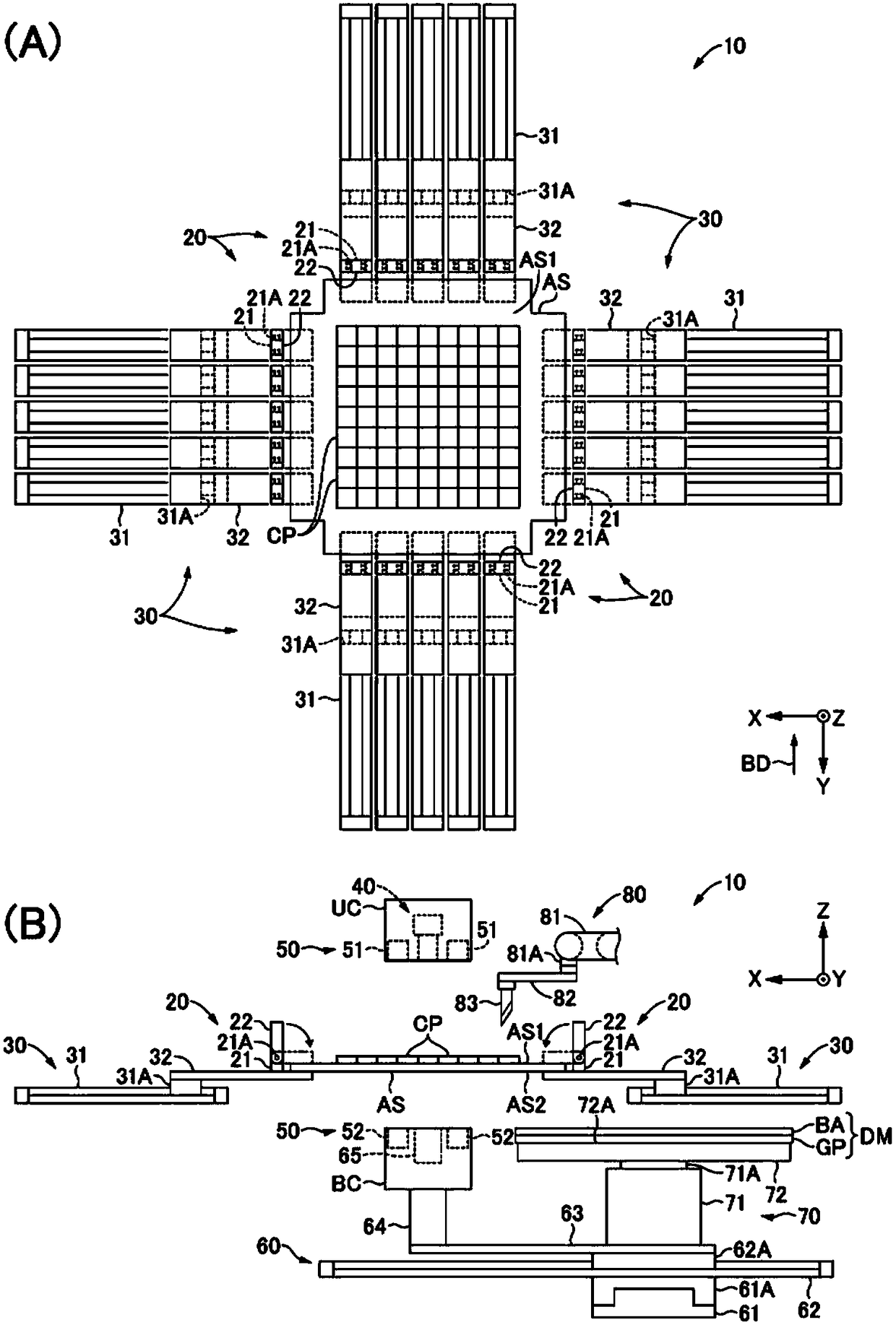

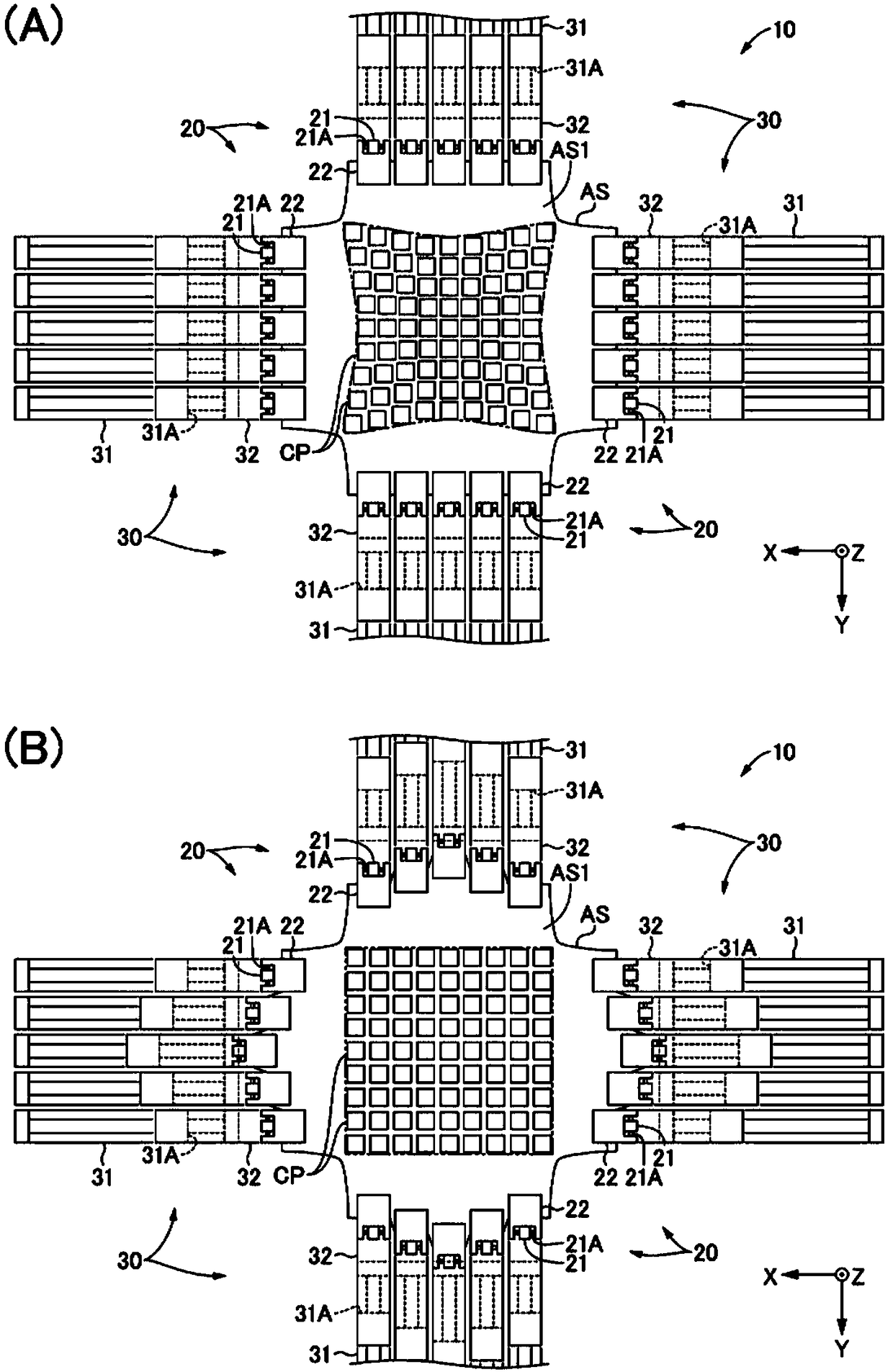

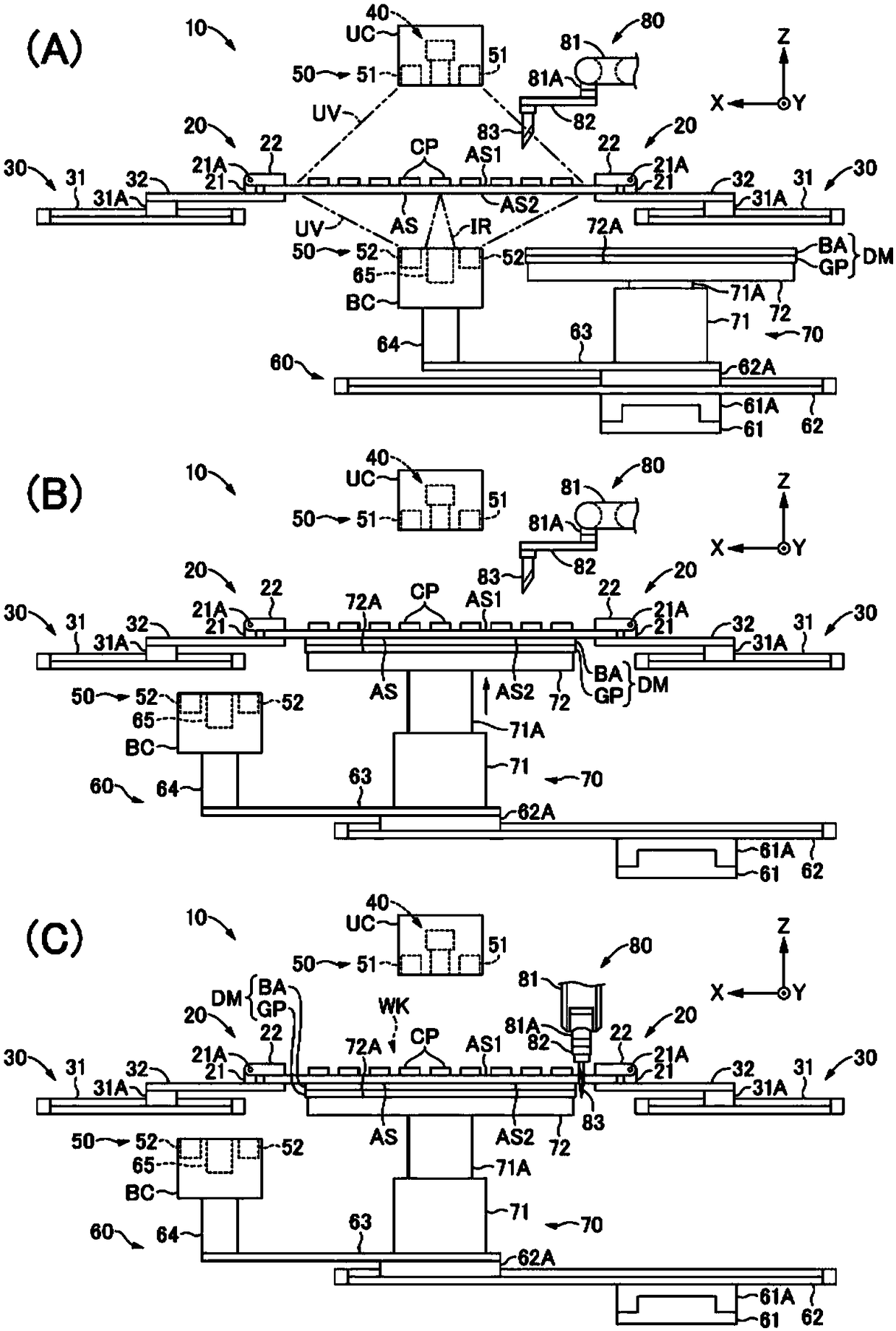

[0034] Hereinafter, embodiments of the present invention will be described based on the drawings.

[0035] It should be noted that the X-axis, Y-axis, and Z-axis in this embodiment are in a relationship of being perpendicular to each other, and the X-axis and the Y-axis are axes within a predetermined plane, and the Z-axis is an axis orthogonal to the above-mentioned predetermined plane. Furthermore, in the present embodiment, when viewing from the direction of the arrow BD parallel to the Y-axis as a reference, when the direction is shown without citing a figure constituting a reference, "up" is defined as the direction of the arrow of the Z-axis. , "Down" as its reverse, "Left" as the arrow direction of the X-axis, "Right" as its reverse, "Front" as the arrow direction of the Y-axis, and "Back" as its reverse Towards.

[0036] The separating device 10 of the present invention is provided with: a plurality of holding units 20, which hold the ends of the adhesive sheet AS on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com