Parallel operation control method for DC power generation system of double-winding induction generator

A technology for induction generators and power generation systems, which is applied in parallel operation of DC power supplies, control of generators, and control of generators through magnetic field changes. It can solve problems such as increased volume and difficult control, and achieves improved reliability and stability. Avoid many parallel conditions and reduce the difficulty of parallel control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The technical solution of the invention will be described in detail below in conjunction with the accompanying drawings.

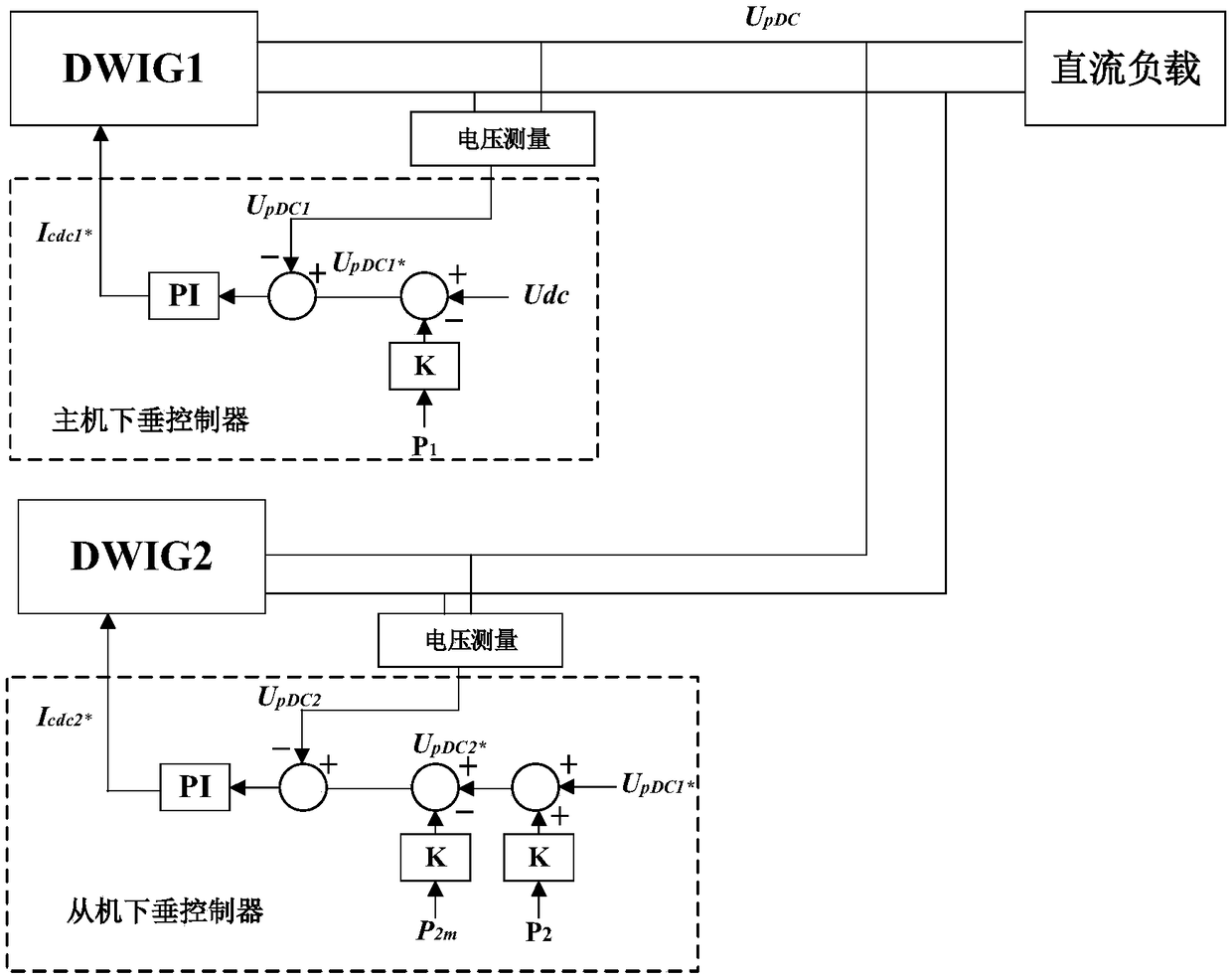

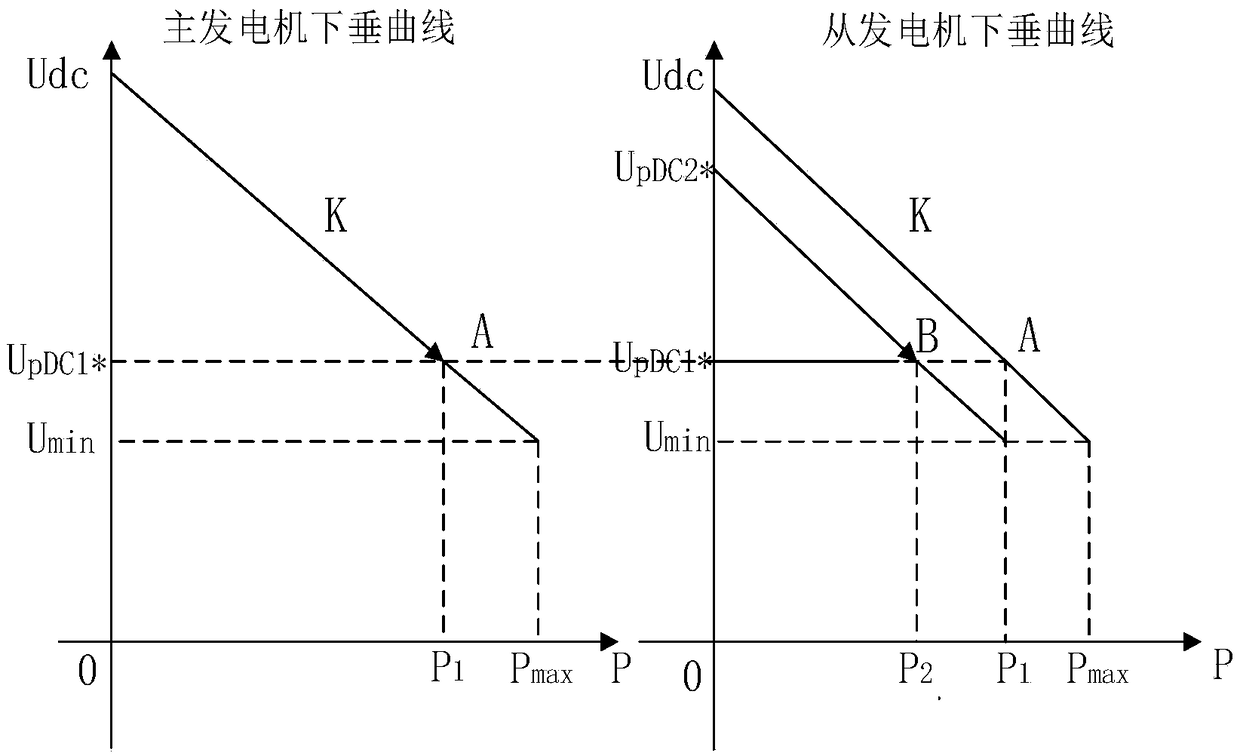

[0018] Two double-winding induction generators operating in parallel in a DC power generation system such as figure 1 As shown, one double-winding induction motor is used as the main generator and connected to the main generator droop controller, and the other double-winding induction motor is used as the slave generator and connected to the slave generator droop controller. When the two generators When the stable output DC voltage is the same, connect the DC output terminal of the secondary generator to the bus bar of the main generator DC output terminal in parallel, and connect the two parallel generators to the DC load.

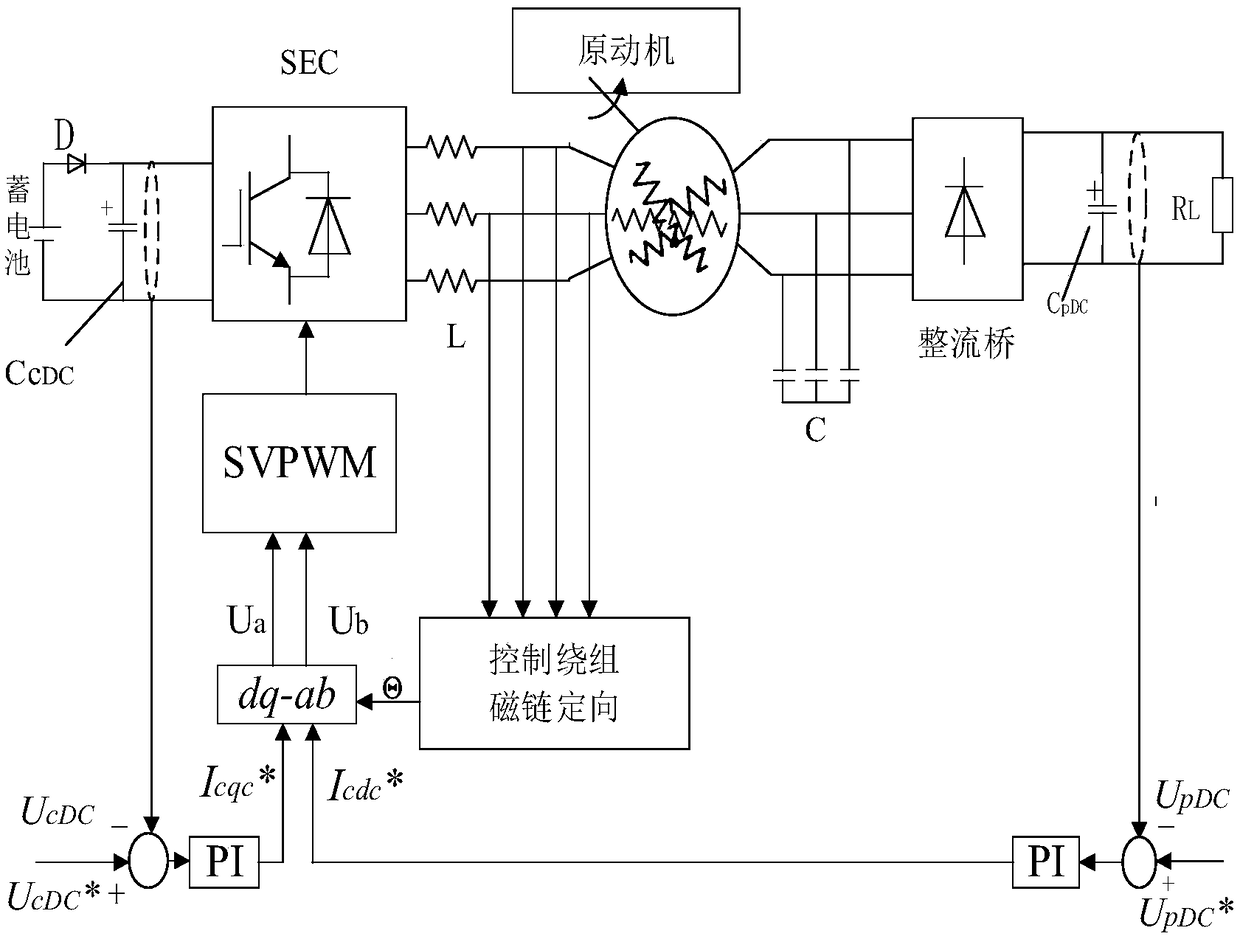

[0019] The control strategy of a single double-winding induction generator DC power generation system is as follows: figure 2 As shown, both generators adopt the same control strategy of controlling winding flux orientation. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com