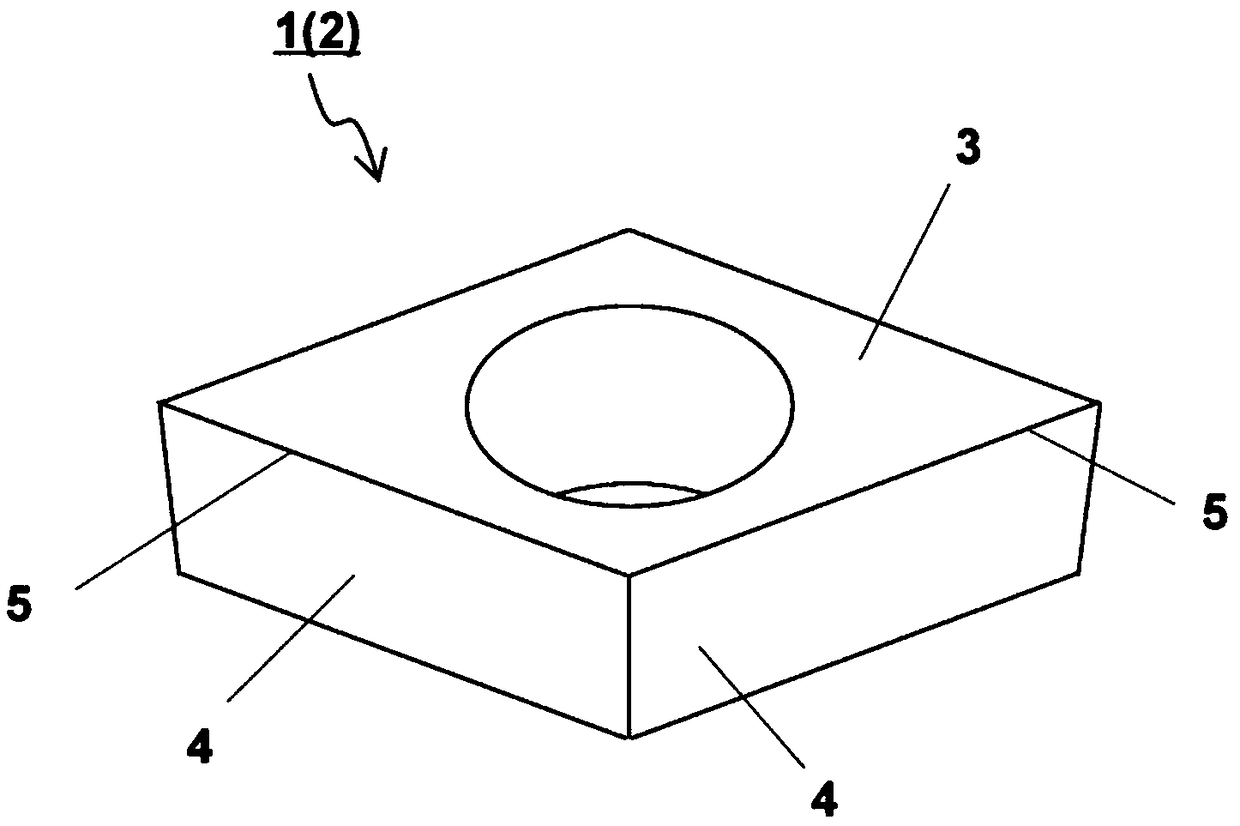

Cutting insert

A technology for cutting inserts and inserts, which is applied in the direction of cutting blades, turning equipment, accessories of toolholders, etc., and can solve the problem of insufficient smoothing of the processed surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

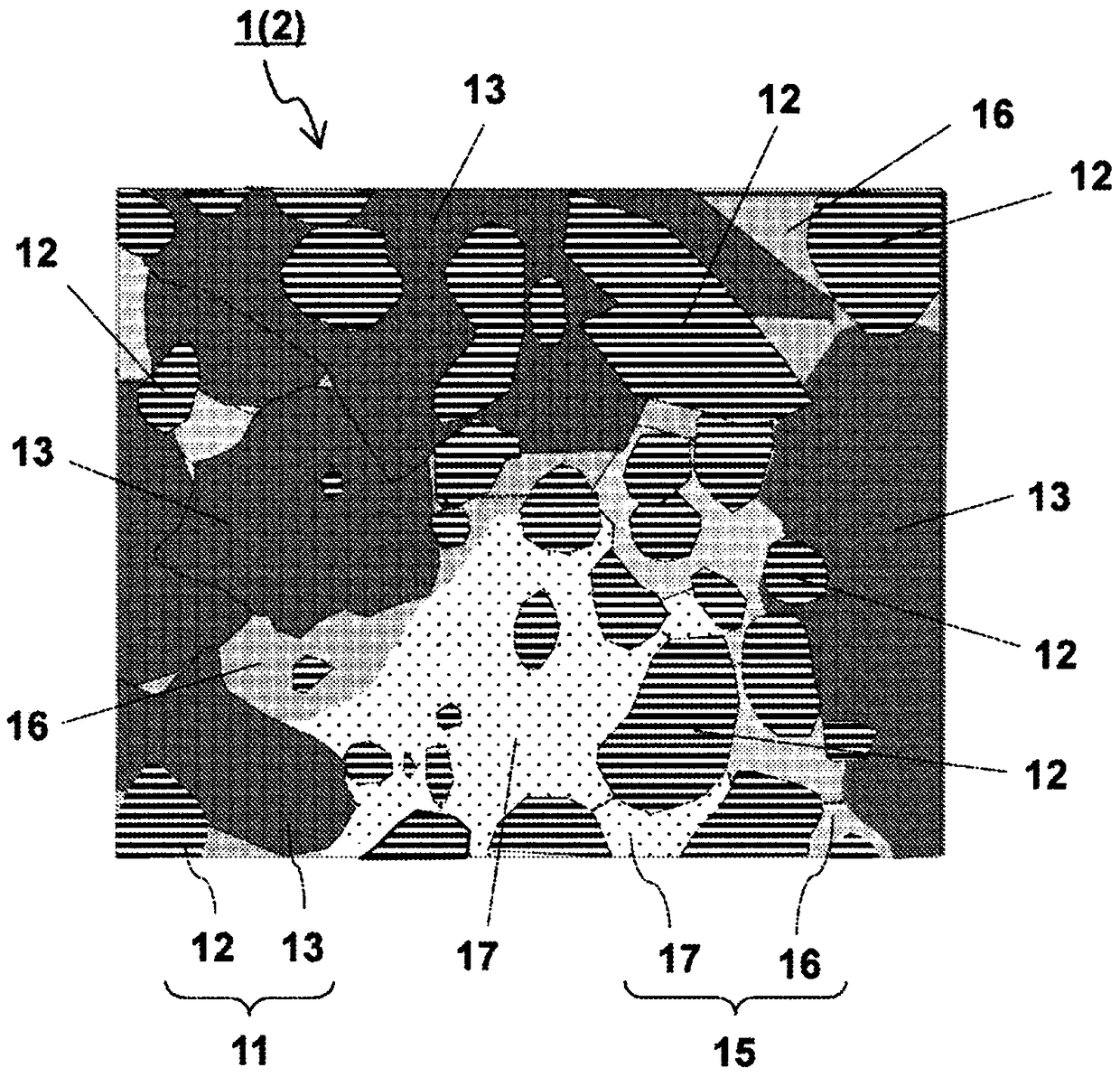

preparation example Construction

[0054] The mixed powder is prepared by adding a binder, a solvent, and the like to the above-mentioned weighed raw material powder, and mixing using a known mixing method such as a ball mill, a vibrating mill, a jet mill, and an ultrafine pulverizer. In this embodiment, a superfine pulverizer is used. The raw material powders are pulverized by powder mixing with an ultrafine pulverizer to reduce the particle size, but metal powders tend to be difficult to pulverize because of their high ductility. Then, the mixed powder is molded into a predetermined shape by a known molding method such as press molding, extrusion molding, and injection molding to produce a molded body.

[0055] Next, according to the present embodiment, the molded body is fired in a vacuum or an inert gas atmosphere. According to the present embodiment, by firing under the following conditions, the base body 2 made of the cermet with the above-mentioned predetermined structure can be produced. As specific f...

Embodiment 1

[0067] By measurement based on the MICROTRAC method, TiCN powder with an average particle size of 0.6 μm, WC powder with an average particle size of 1.1 μm, TiN powder with an average particle size of 1.5 μm, TaC powder with an average particle size of 2 μm, and NbC powder with an average particle size of 1.5 μm, MoC powder with an average particle size of 2 μm, ZrC powder with an average particle size of 1.8 μm, VC powder with an average particle size of 1 μm, Ni powder with an average particle size of 2.4 μm and an average particle size of 1.9 μm Co powder, and W powder or WC 0.5 The powders were adjusted at the ratios shown in Table 1 to prepare mixed powders.

[0068] Isopropyl alcohol (IPA) and paraffin wax were added to the mixed powder, and a stainless steel ball mill and ultrahard balls were added, and mixed with an attritor to prepare a slurry. This slurry was granulated by spray drying to produce granulated powder, and the granulated powder was press-molded at 150 M...

Embodiment 2

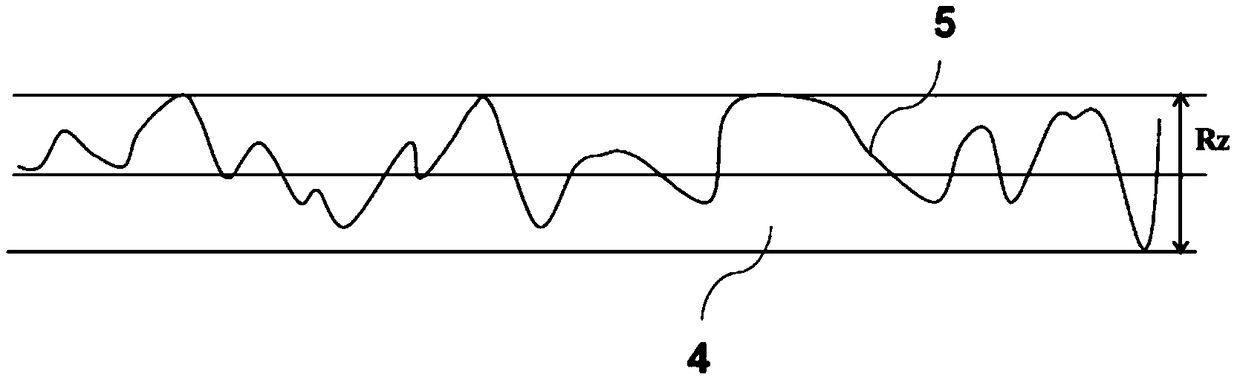

[0105] Using sample No. 1 of Example 1, the grinding method shown in Table 6 was changed and processed to produce cutting edges. For the obtained inserts, the maximum height, the arithmetic mean roughness, the residual stress of the first hard phase and the second hard phase, and the presence or absence and direction of grooves on the second surface were measured in the same manner as in Example 1. In addition, the cutting performance was evaluated under the same cutting conditions as in Example 1.

[0106] [Table 6]

[0107]

[0108] [Table 7]

[0109]

[0110] According to Tables 6 to 7, sample No. II- 1 to 3 are all products in which the surface roughness of the processed surface is smooth, there is no darkening of the processed surface, and the cutting length is poor.

[0111] In addition, in Sample Nos. II-1 and 2 in which the second surface has a plurality of grooves extending parallel to the cutting edge, the shape of the grooves is difficult to transfer to the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com