Pulley for an elevator with a friction reducing coating and method for manufacturing same

An anti-friction coating, pulley technology, applied in the manufacture of pulleys for elevators, in the field of elevators, which can solve problems such as shortened service intervals, improper guidance or misalignment of suspended traction members

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

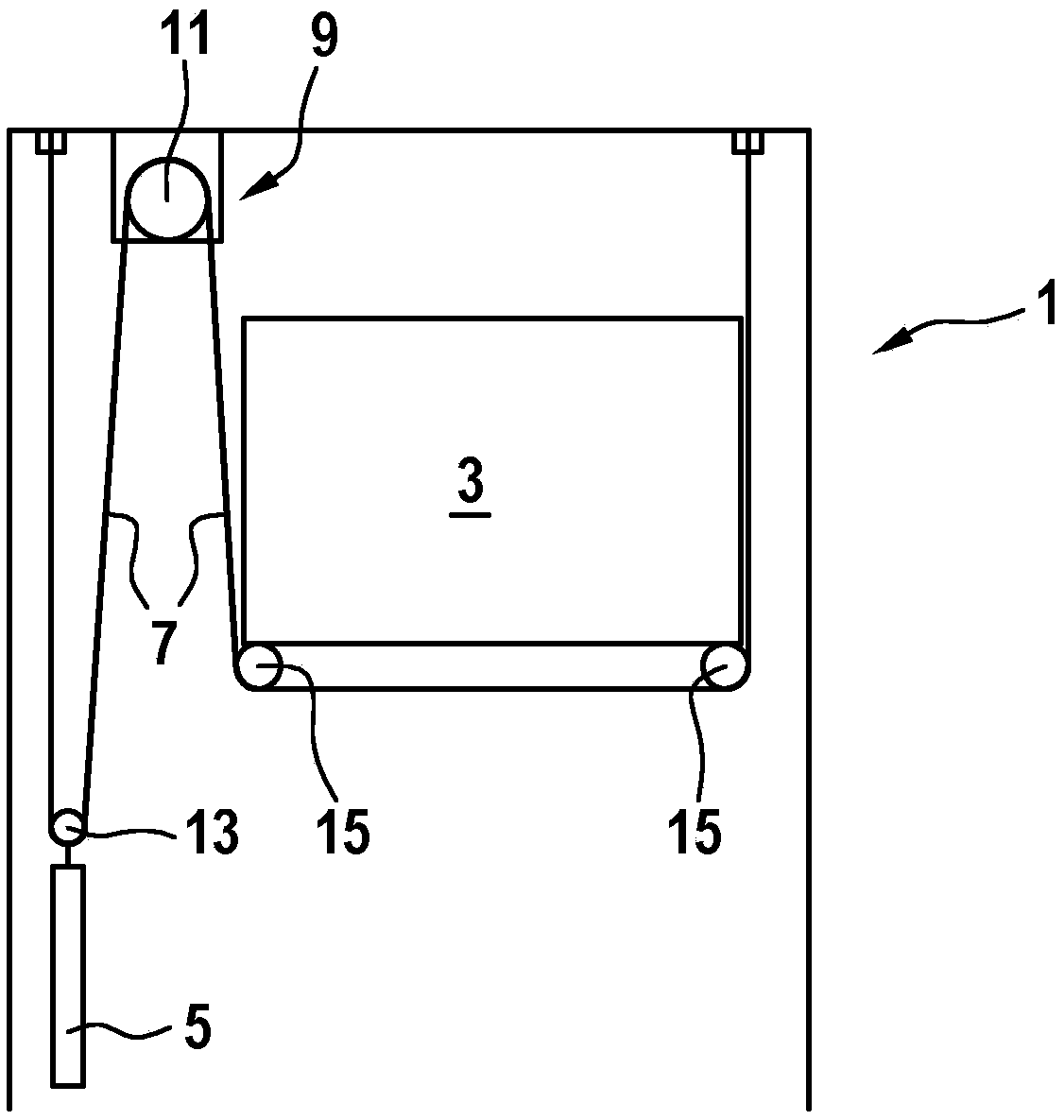

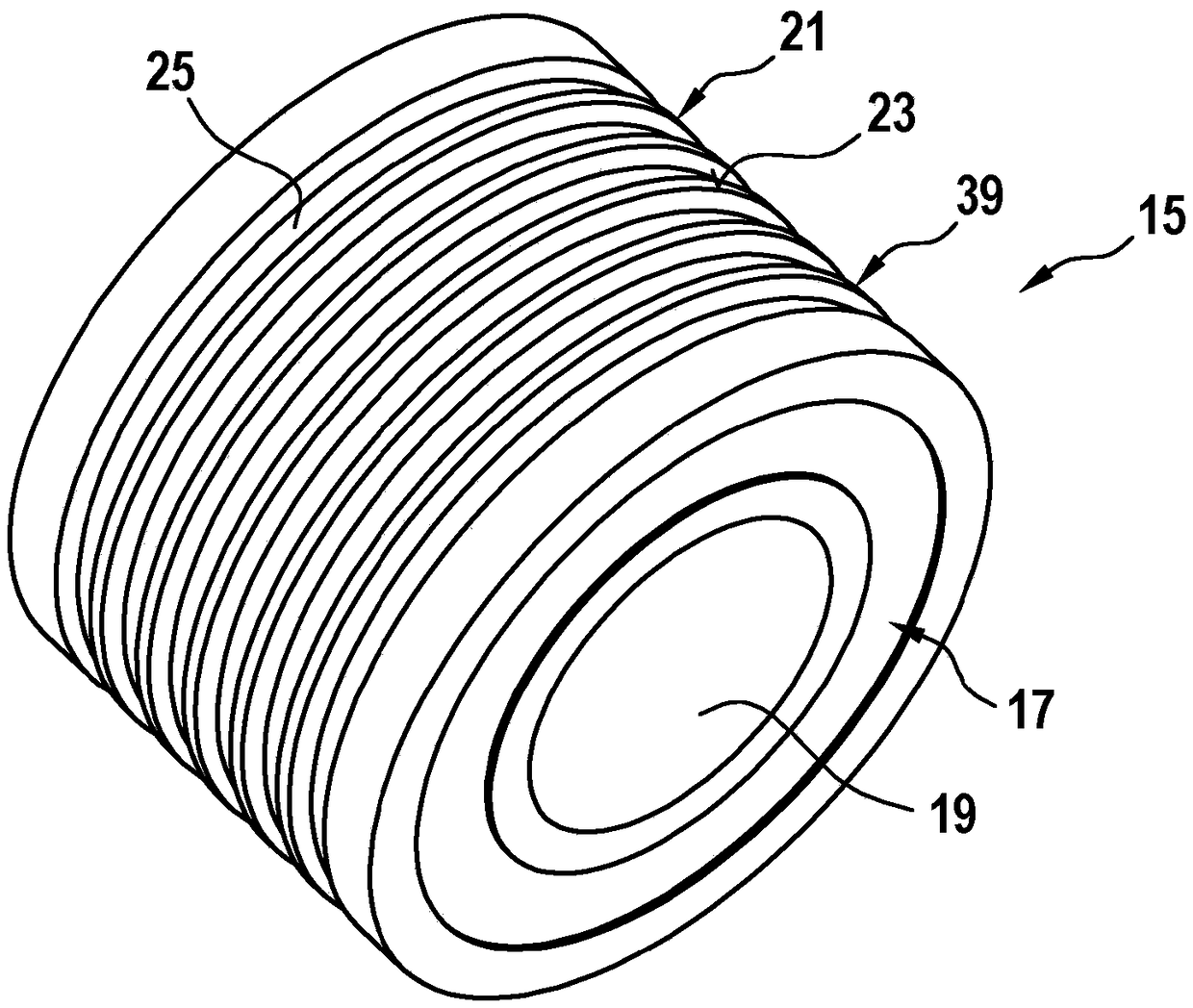

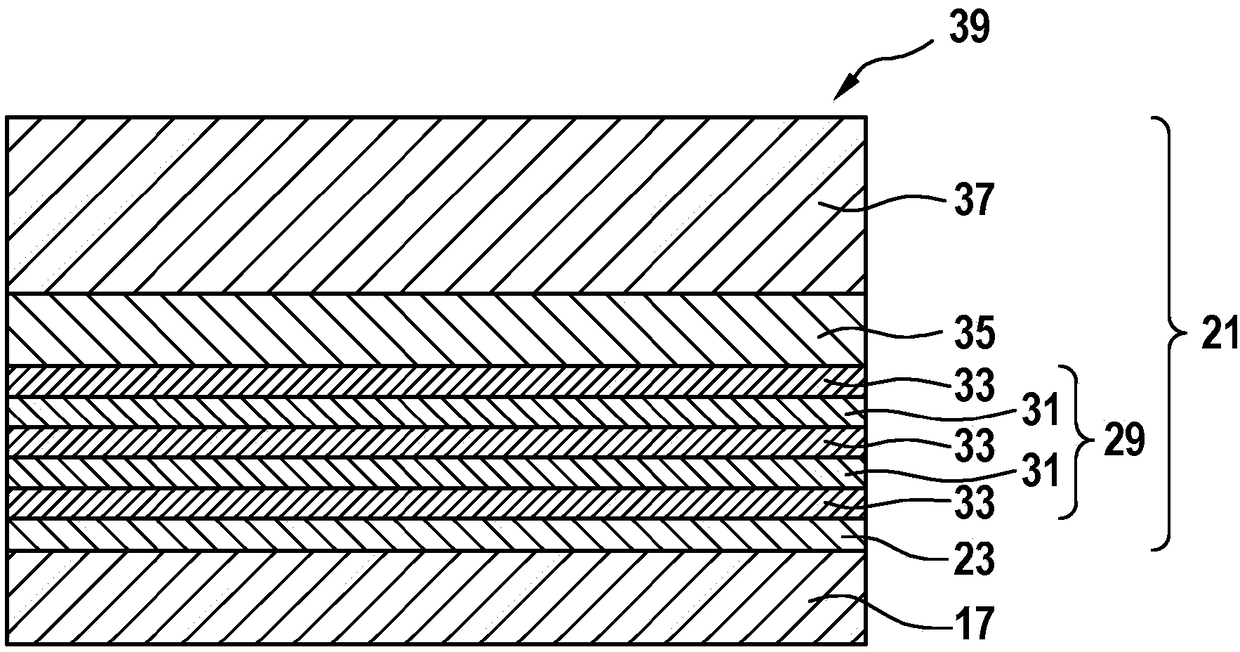

[0054] figure 1 The basic components of the elevator 1 are shown. The elevator 1 comprises a car 3 and a counterweight 5 . Both the car 3 and the counterweight 5 are supported by suspended traction members 7, which are typically formed from a plurality of elongated strips. Each strip includes a plurality of load-bearing wires encapsulated in a polyurethane covering. The suspended traction member 7 can be driven by a drive motor 9 , wherein an electric motor can rotate the traction wheels 11 . The suspension traction member 7 supports the car 3 and the counterweight 5 via pulleys 13, 15, respectively. The pulleys 13, 15 may be fixed eg to the top and / or bottom of the car 3 and / or counterweight 5, respectively.

[0055] In the following structure of the elevator 1: the traction sheave 11 will actively displace the suspension traction member 7, that is, the traction sheave 11 is actively driven to rotate, and then should be contacted by the contact surface of the traction she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com