Automatic screening device for pearls

An automatic sieving and pearl technology, applied in the field of pearl processing, can solve the problems of relying on the accuracy of sieving, increasing the labor cost of the enterprise, and reducing the processing efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

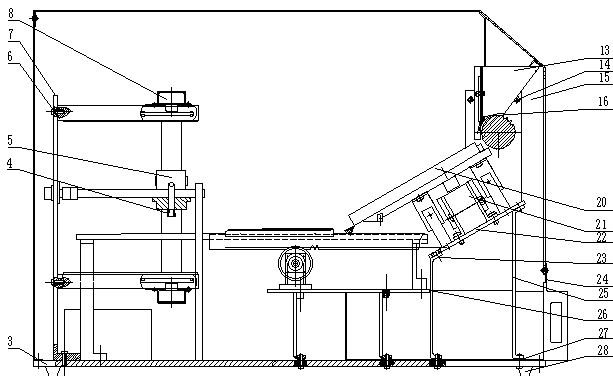

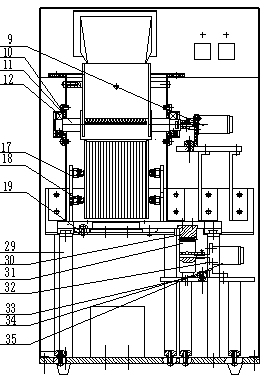

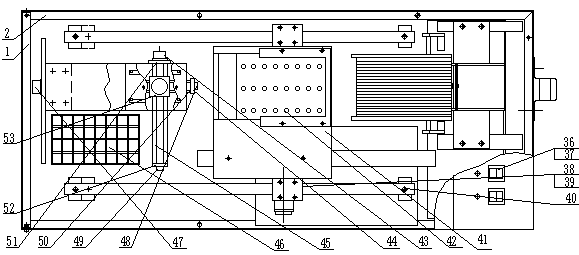

[0035] like Figure 1~19 As shown, an automatic pearl screening device includes a rear panel (1), a cover plate (2), a bottom plate (3), a rubber suction head (4), an air pump (5), a camera support plate (6), a support Plate (7), CCD industrial camera (8), blanking shaft drive stepping motor (9), bearing support (10), blanking shaft (11), deep groove ball bearing (12), feeding hopper (13 ), flat head screw (14), left side plate (15), brush (16), right side plate (17), M6 bolt (18), M6 screw (19), vibrating material plate (20), vibrator ( 21), vibration bottom plate (22), M5 screw (23), lifting lug (24), vibrator upper support (25), vibrator lower support (26), M8 bolt (27), bottom plate support (28), shaft Drive the stepper motor (35) and switch button (36) to the support plate (29), rack (30), gear (31), M3 screw (32), M7 screw (33), motor seat (34), and sampling plate ), reminder light (37), linear slide rail (38), hexagon socket bolt (39), linear slide rail support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com