Pipeline type magnetic suspension train

A maglev train and pipeline-type technology, applied to tracks, roads, motor vehicles, etc., can solve the problems of complex braking system, low payload, high error probability, etc., and achieve the effect of simple control system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

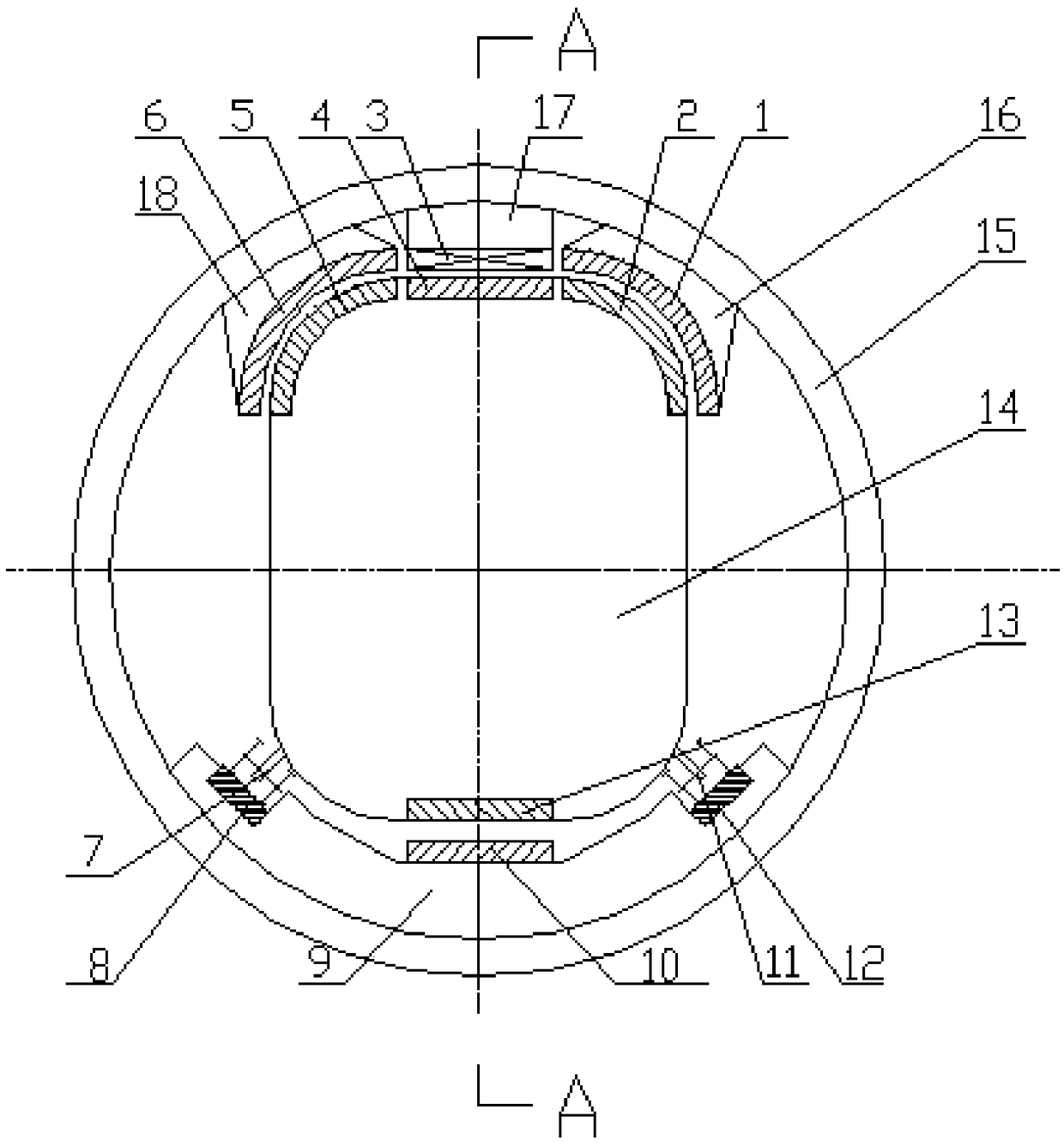

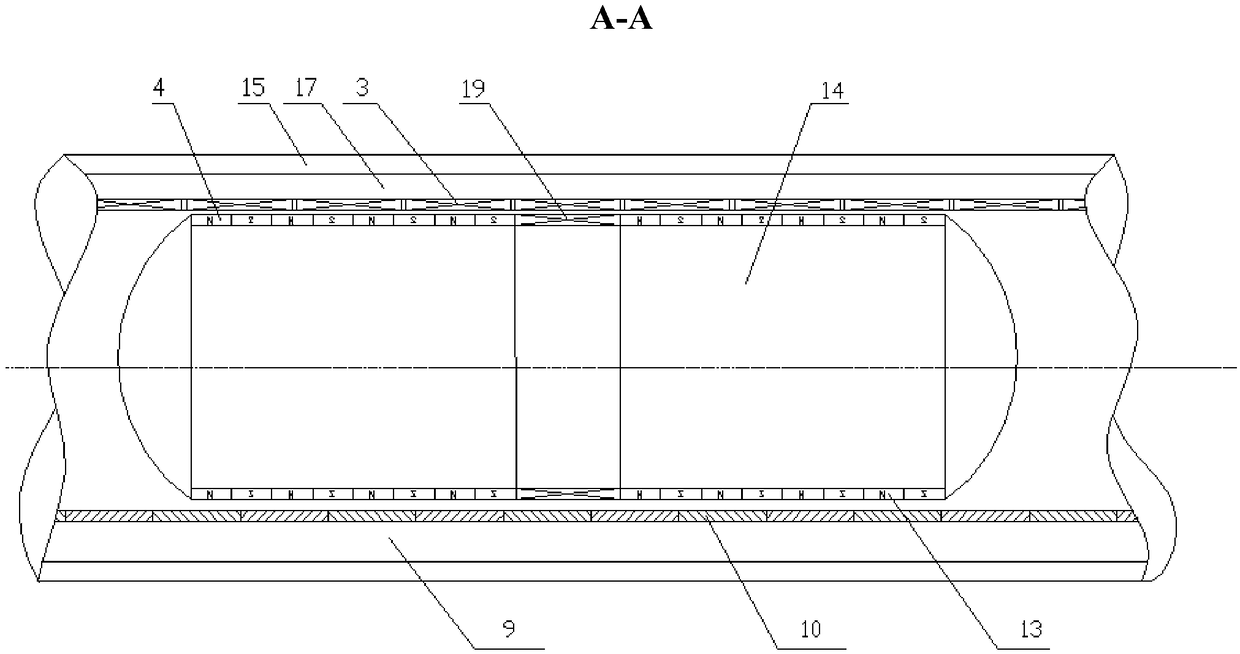

[0032] The present invention will be further described below in conjunction with accompanying drawing. Such as Figure 1-2 Shown, a pipeline-type maglev train includes a suspension device, a guiding device, a driving device, a running device, a current collecting device and a pipeline device.

[0033] The suspension device is composed of a lower moving maglev body 13 and a lower fixed maglev plate 10; the lower moving maglev body 13 is installed on the bottom of the train case 14 along the running direction of the train; the lower fixed maglev plate 10 is installed on the wheel rail On the support boss 9.

[0034] Described guiding device is made up of left moving maglev body 5, left fixed maglev plate 6, right moving maglev body 2 and right fixed maglev plate 1; Upper left corner area; the left fixed magnetic levitation plate 6 is installed on the left frame 18 in the pipeline 15; there is a layer of uniform gap between the left moving magnetic levitation body 5 and the lef...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com