Pipeline bearing structure of pipeline suspension transportation tool

A technology for load-bearing structures and means of transportation, applied to roads, tracks, tunnel systems, etc., can solve the problems of not utilizing the bending resistance characteristics of large-diameter pipes, unfavorable concrete stress, and no consideration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in detail below in conjunction with specific examples and accompanying drawings.

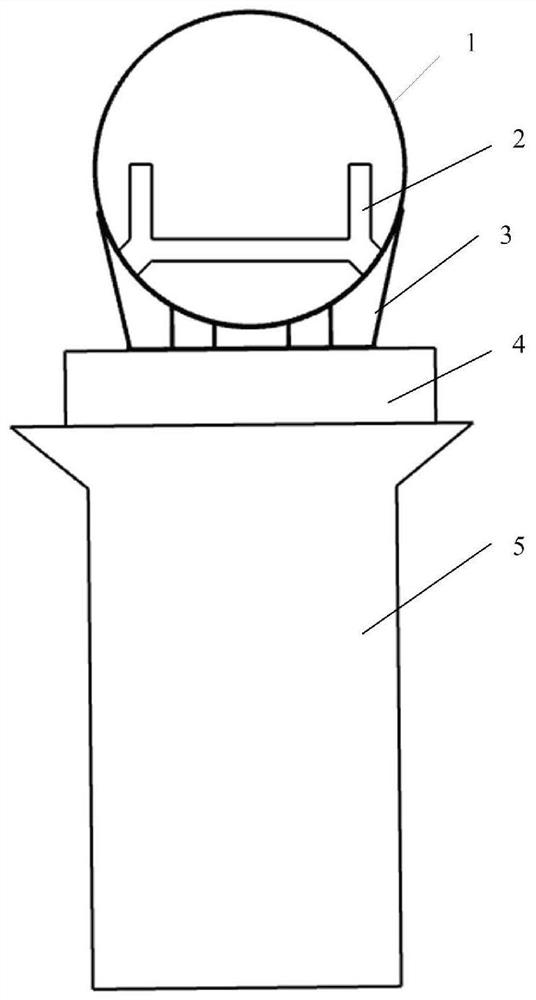

[0026] In order to ensure the vacuum, the pipe wall needs a certain thickness, and the non-load-bearing scheme of the pipeline does not fully utilize the load-bearing capacity of the steel pipe, resulting in a certain waste of rigidity. Therefore, the present invention proposes a pipeline load-bearing scheme. A pipeline bearing structure of a pipeline suspension transportation tool, such as figure 1 As shown, it includes a pipeline system 1 , a track system 2 , a pipeline support 3 , a platform 4 and a main bearing structure 5 .

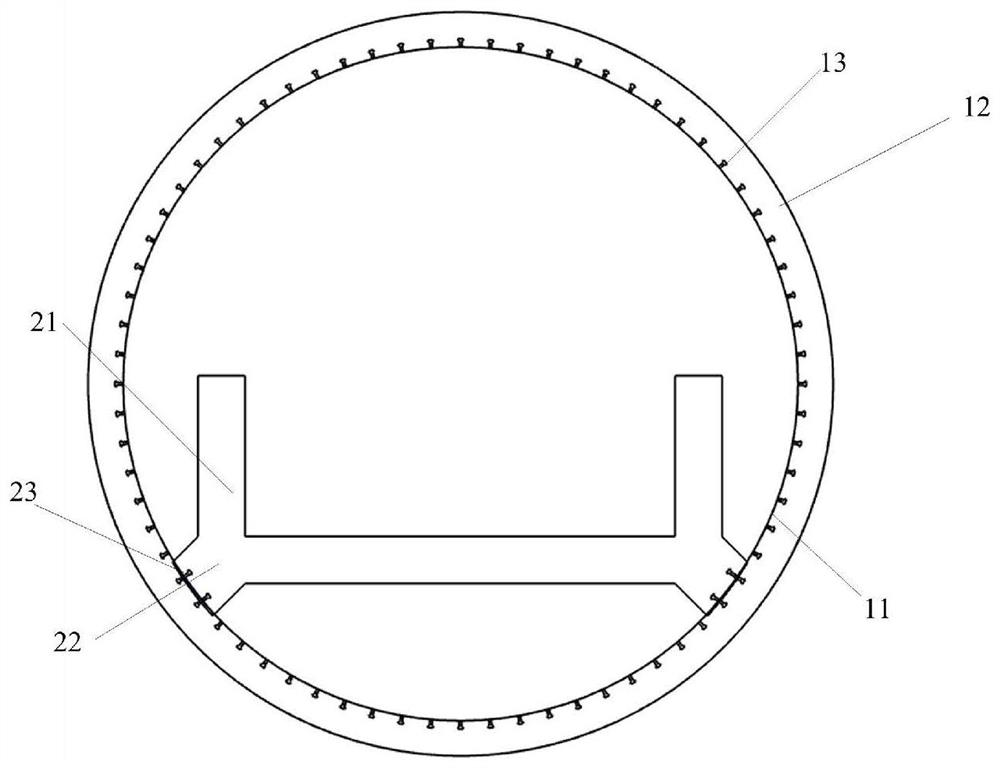

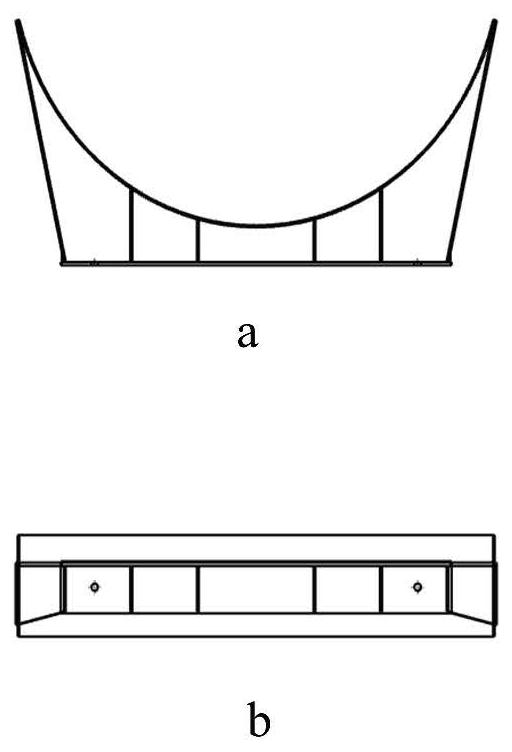

[0027] The pipeline system 1 is composed of an inner pipe 11 and an outer pipe 12. The cross section of the inner and outer pipes is circular. The inner pipe 11 is made of metal material, the outer pipe 12 is made of concrete material, and the inner pipe 11 is uniformly distributed in the circumferential direction and radi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com