Coiling device for textile fabric grey yarns

A textile fabric and winding technology, applied in the field of original yarn winding, can solve the problems of low winding efficiency and unstable winding quality, and achieve the effect of improving production efficiency, improving winding efficiency and ensuring winding.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

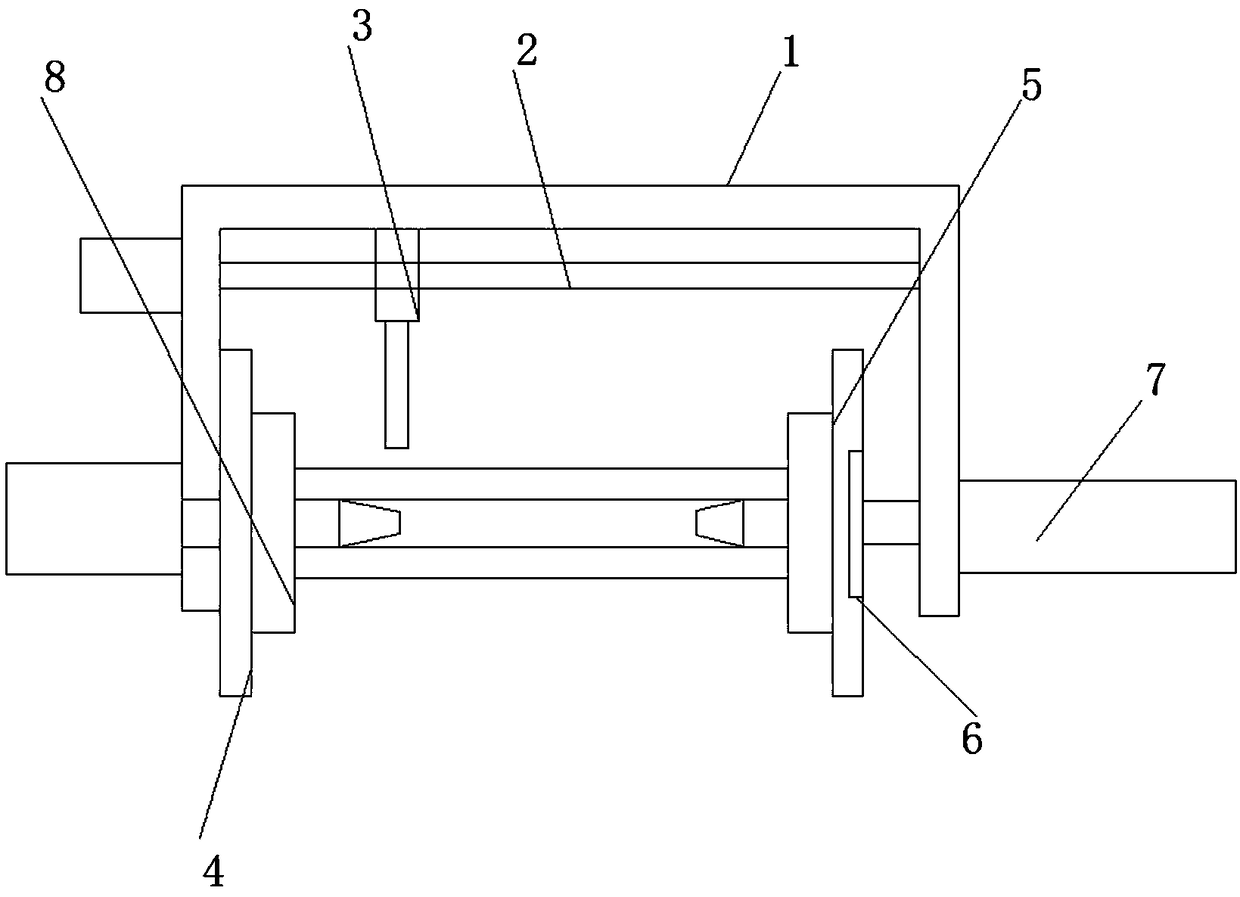

[0019] A control box is installed on the top of the rack 1, and a controller is installed inside the control box. The controller adopts an ARM single-chip microcomputer. The controller is connected to the first mechanical switch, the second mechanical switch, the first push rod motor 7, and the second push rod motor. 11. The first motor and the second motor are electrically connected, and guide posts are welded on the sides of the two groups of contact plates 8 that are close to each other.

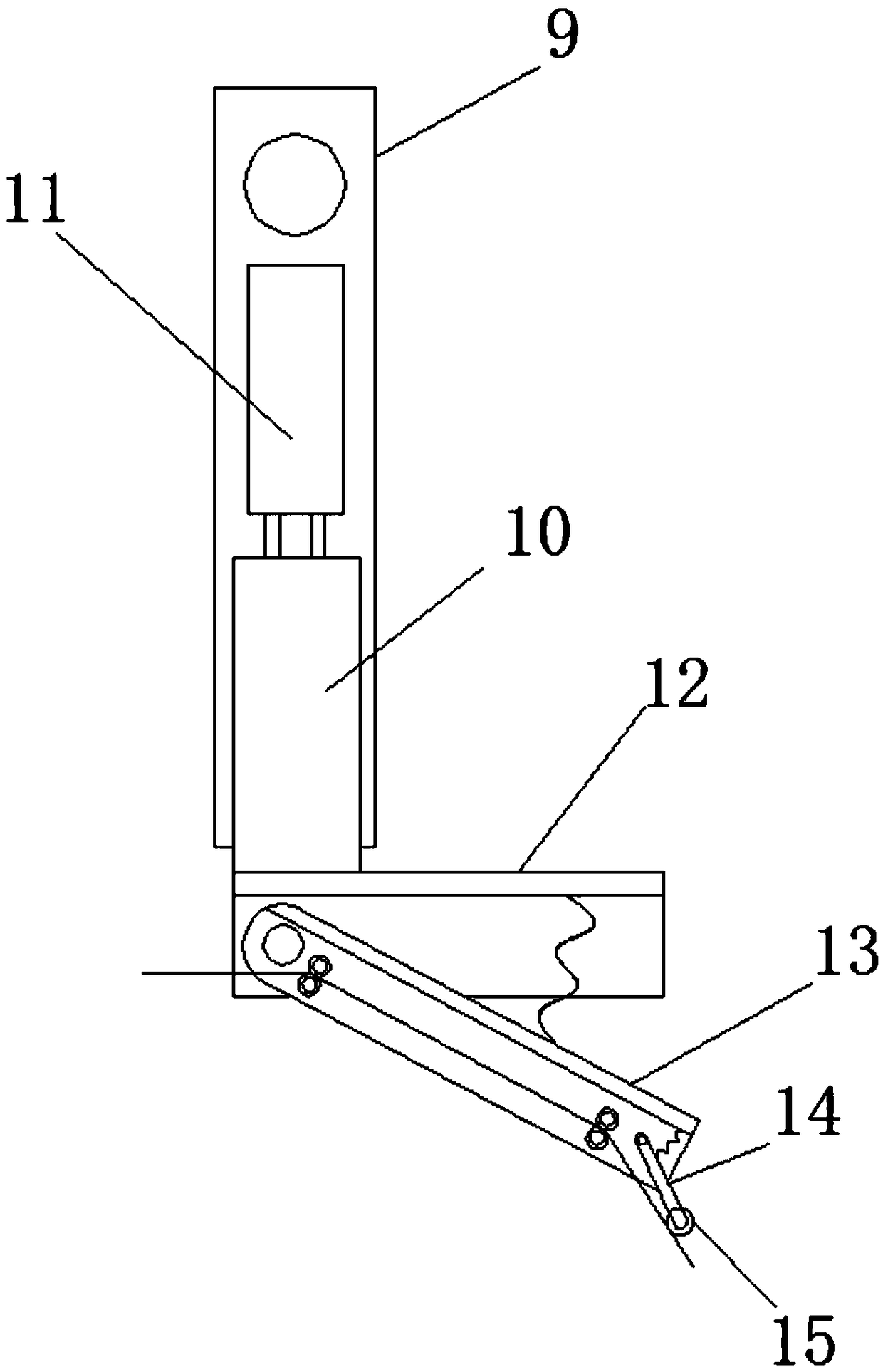

[0020] Working principle: When in use, place the reel used for original yarn winding on the guide column on the contact plate 8 on the drive turntable 4, and then the first push rod motor 7 is activated to lift the clamping turntable 5 toward the drive turntable. 4, so as to clamp the reel, and then the second push rod motor 11 on the push plate 10 is activated to push the push plate 10 to move downward, so that the pressing roller 15 at the bottom of the pressing plate 14 is connected to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com