Preparation method of click chemical synthesis of graphene oxide grafted fluoropolymer

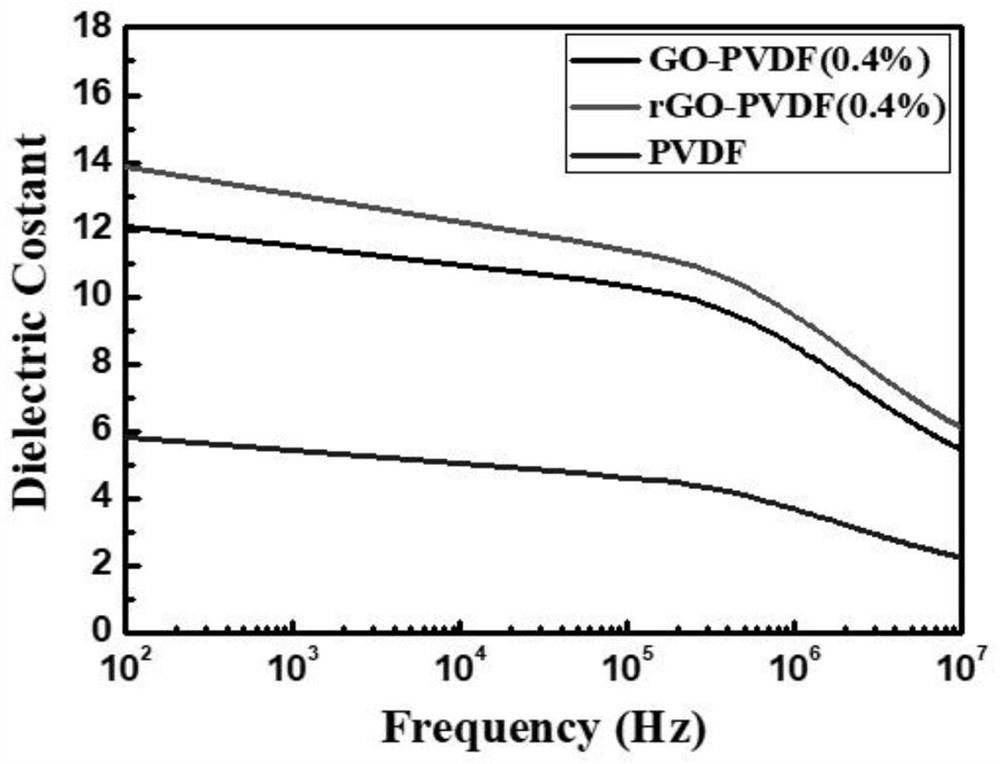

A technology of synthetic oxidation and click chemistry, applied in the field of materials, can solve problems such as unstable modification methods, and achieve the effects of improving compatibility, simple process and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

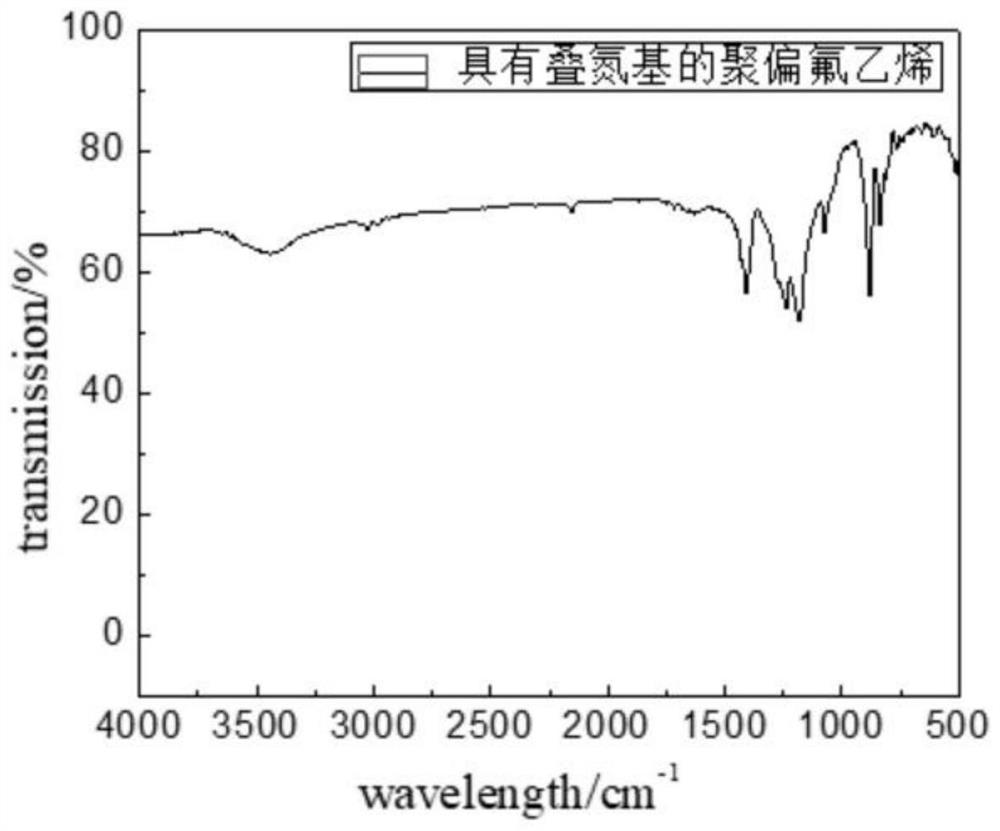

[0043] A preparation method for click chemical synthesis of graphene oxide grafted fluoropolymer, comprising the following steps:

[0044] 1) Prepare graphene oxide by improving Hummer's method

[0045] Under the condition of ice-water bath, 3g graphite powder, 15g KMnO 4 Add 115mL of 98% concentrated H 2 SO 4 Stir in a beaker, heat up to 45°C, and stop after 12 hours of reaction; under ice-water bath conditions, pour the reaction product into a large beaker filled with 200mL distilled water, and add 15mL of 30% volume concentration of H 2 o 2 , the solution color changed from dark brown to golden brown; with 100mL dilute H with a molar concentration of 1mol / L 2 SO 4 and distilled water repeatedly washed until the solution is neutral, vacuum-dried to obtain graphene oxide;

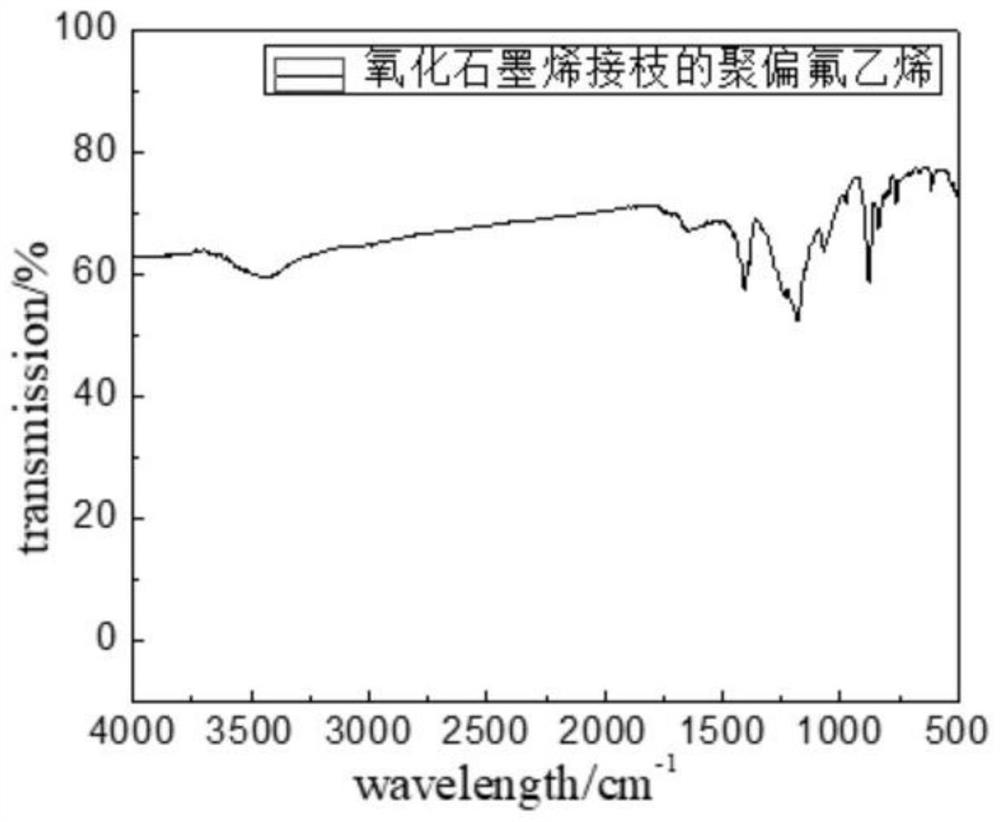

[0046] (2) Alkynylation of graphene oxide

[0047] Weigh 0.1641g of graphene oxide obtained in step (1) and disperse it in 100mL of anhydrous tetrahydrofuran by ultrasonic for 5min, add it into the ...

Embodiment 2

[0056] A preparation method for click chemical synthesis of graphene oxide grafted fluoropolymer, comprising the following steps:

[0057] (1) adopt improved Hummer's method to prepare graphene oxide, and preparation process is with above-mentioned embodiment 1;

[0058] (2) Alkynylation of graphene oxide:

[0059] Weigh 0.1641g of graphene oxide obtained in step (1) and disperse it in 100mL of anhydrous N,N-dimethylformamide by ultrasonic for 10min, add it into the flask and stir, then add 0.1032g of propiolic acid, 0.0018g of 4- Dimethylaminopyridine and 0.0103g dicyclohexylcarbodiimide were subjected to an esterification reaction, reacted at room temperature for 6h, filtered, and dried in vacuum to obtain graphene oxide with alkynyl groups;

[0060] (3) Azidation of fluoropolymers

[0061] Take 200mL of N-methylpyrrolidone, weigh 0.27g of tert-butyl peroxypivalate and 1.0324g of perfluoroiodohexane into the reaction kettle, and then feed 15g of vinylidene fluoride gas mon...

Embodiment 3

[0067] A preparation method for click chemical synthesis of graphene oxide grafted fluoropolymer, comprising the following steps:

[0068] (1) adopt improved Hummer's method to prepare graphene oxide, and preparation process is with above-mentioned embodiment 1;

[0069] (2) Alkynylation of graphene oxide:

[0070] Weigh 0.1641g of graphene oxide obtained in step (1) and disperse it ultrasonically in 40mL of anhydrous tetrahydrofuran for 5min, add to the flask and stir, then add 0.019g of propiolic acid, 0.0018g of 4-dimethylaminopyridine and 0.006g of dimethicone Cyclohexylcarbodiimide is subjected to an esterification reaction, reacted at room temperature for 1h, filtered, and vacuum-dried to obtain graphene oxide with an alkynyl group;

[0071] (3) Azidation of fluoropolymers:

[0072] Take 200mL trifluorotrichloroethane, weigh 0.0718g tert-butyl peroxypivalate and 0.669g perfluoroiodohexane into the reaction kettle, and then feed 14.4g of vinylidene fluoride gas monomer ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap