Mixers for exhaust aftertreatment systems

A technology of exhaust post-treatment and mixer, which is applied in exhaust treatment, exhaust device, machine/engine, etc., can solve the problem of excessive exhaust back pressure in the mixer structure, uneven mixing of ammonia gas, and excessive mixer size. Large and other problems, to achieve the effect of good mixing effect, efficient mixing effect and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with specific drawings and embodiments.

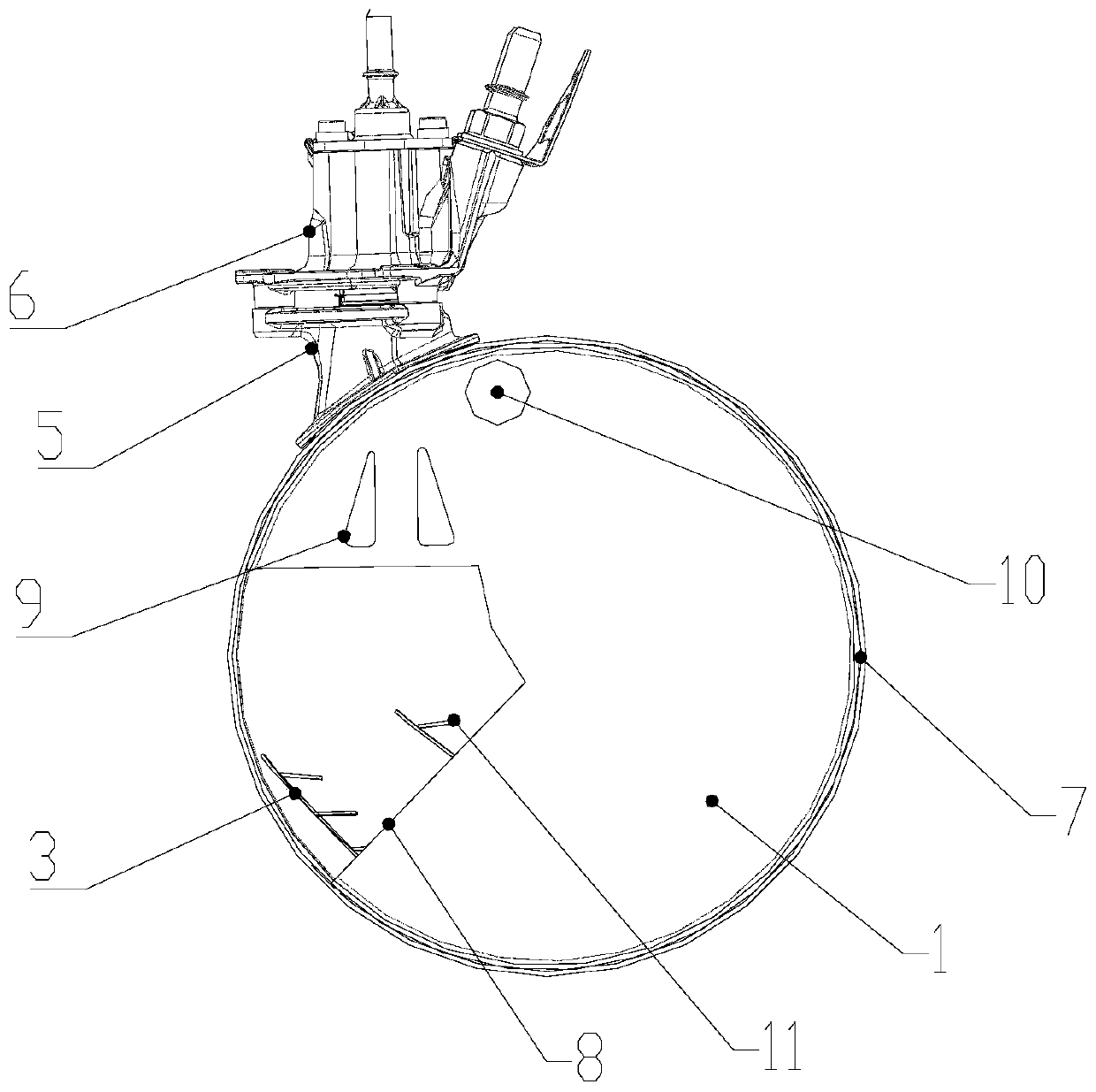

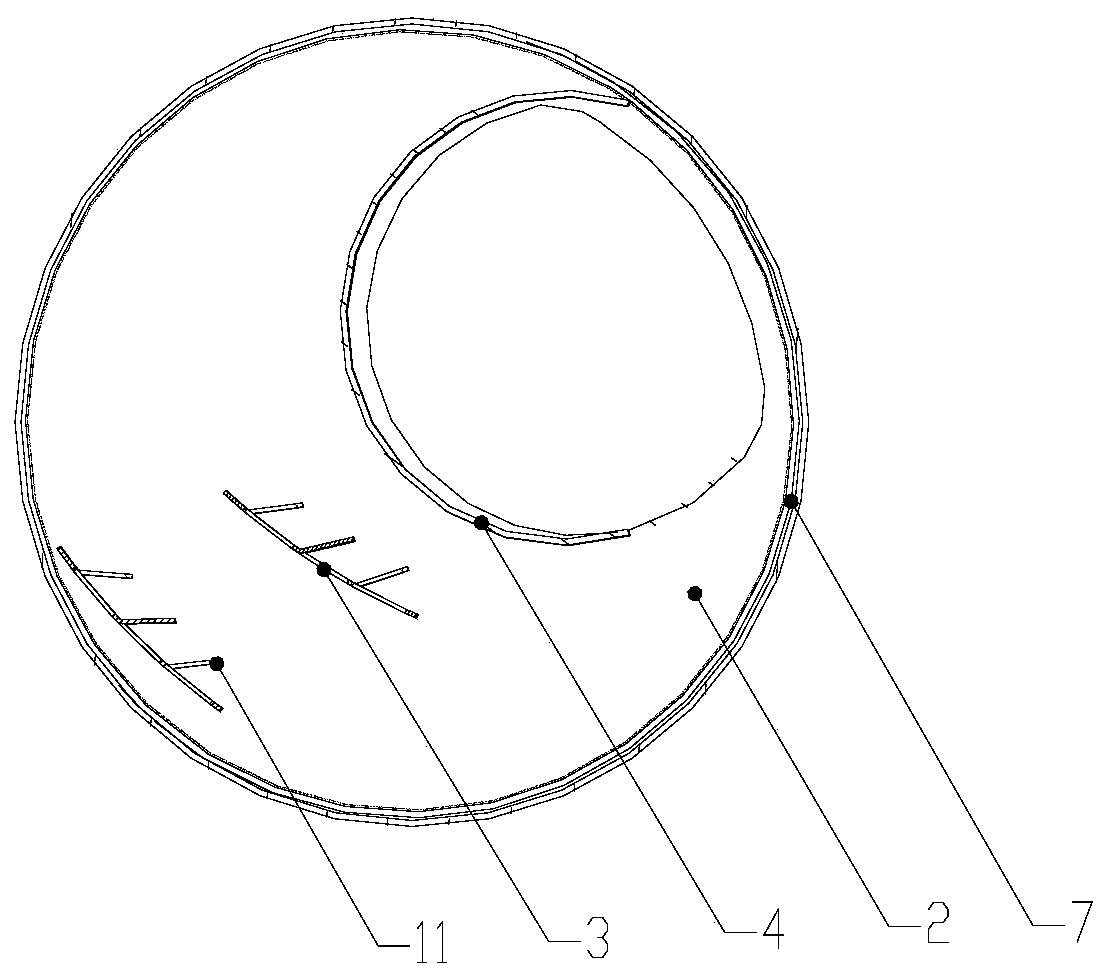

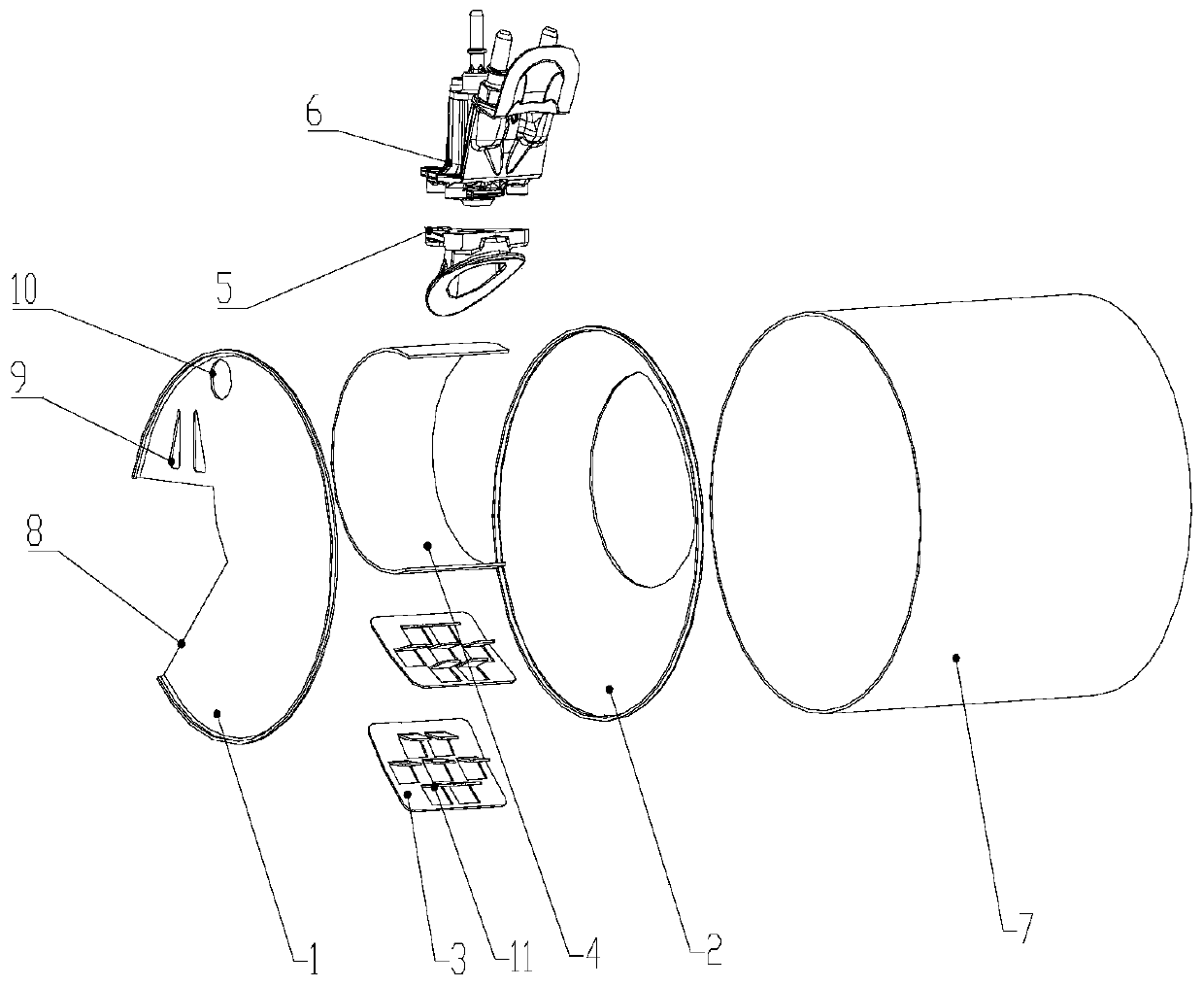

[0029] Such as Figure 1~Figure 3 As shown, the present invention provides a mixer for exhaust aftertreatment system, including a front baffle 1, a rear baffle 2, an arc plate 3, a cylindrical plate 4, a base 5, a nozzle 6 and a barrel 7 , where the front partition 1 and the rear partition 2 are installed inside the cylinder 7, the two ends of the arc plate 3 and the cylindrical plate 4 are connected to the front partition 1 and the rear partition 2, and the base 5 is installed on the cylinder 7 On, the nozzle 6 is installed on the base 5.

[0030] After the exhaust gas enters the exhaust system, it goes from DOC to DPF and then reaches the front end of the mixer. At this time, the gas is evenly distributed in the cross-sectional direction of the cylinder 7. Under the drainage effect of the front bulkhead 1, the exhaust gas passes through the through holes of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com