A method for testing the performance of a rotary evaporator

A rotary evaporator and instrument technology, which is applied in the general physical or chemical field, can solve problems such as strict control and detection, influence on test results, uneven use accuracy, etc., achieve good versatility, suitable for popularization and application, and improve The effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific embodiments of the present invention will be described in further detail below.

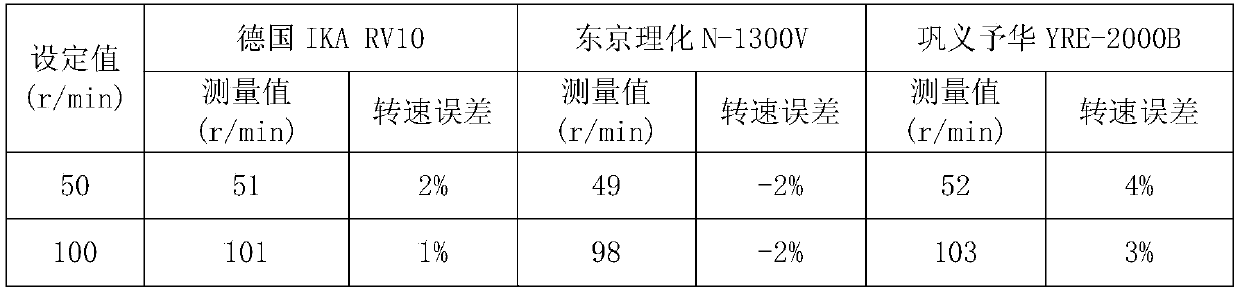

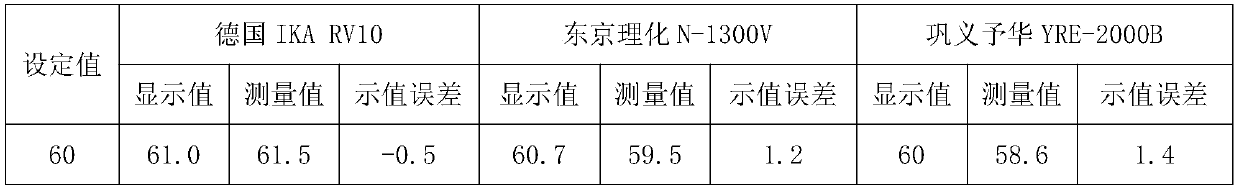

[0025] The method for testing the instrument performance of a rotary evaporator in a specific embodiment includes: preparing three rotary evaporators to be tested, namely IKA RV10 rotary evaporator (IKA company in Germany), equipped with IKA KV600 circulating condenser; N-1300V rotary Evaporator (Tokyo Rika), equipped with Minichiller 900w Circulating condenser (German huber company); YRE-2000B rotary evaporator (Gongyi Yuhua Instrument Co., Ltd.), equipped with DLSB-30 / 30 circulating condenser (Zhengzhou Great Wall Science, Industry and Trade Co., Ltd.).

[0026] Prepare testing equipment (all certified equipment that meets measurement requirements), including: HT-5500 digital tachometer (Ono Sokki, Japan); MarCator 1086R 25mm digital dial indicator (Mahr, Germany); K-type cheap metal Thermocouple (FLUKE, USA); HX 601B intelligent pressure calibrator (Hua Xin Instrument (Beijing)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com