Six-knife cable stripper

A stripper and cable technology, which is applied in the direction of cable installation, cable installation device, dismantling/armouring cable equipment, etc. It can solve the problem that the emergency repair work cannot be implemented by the user's live connection construction, the stripping accuracy is difficult to control, and the physical exertion of personnel is large. and other problems to achieve the effects of stable peeling quality, time-saving and labor-saving efficiency, and reduced operating intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific technical solutions of the present invention are further described below, so that those skilled in the art can further understand the present invention, without limiting their rights.

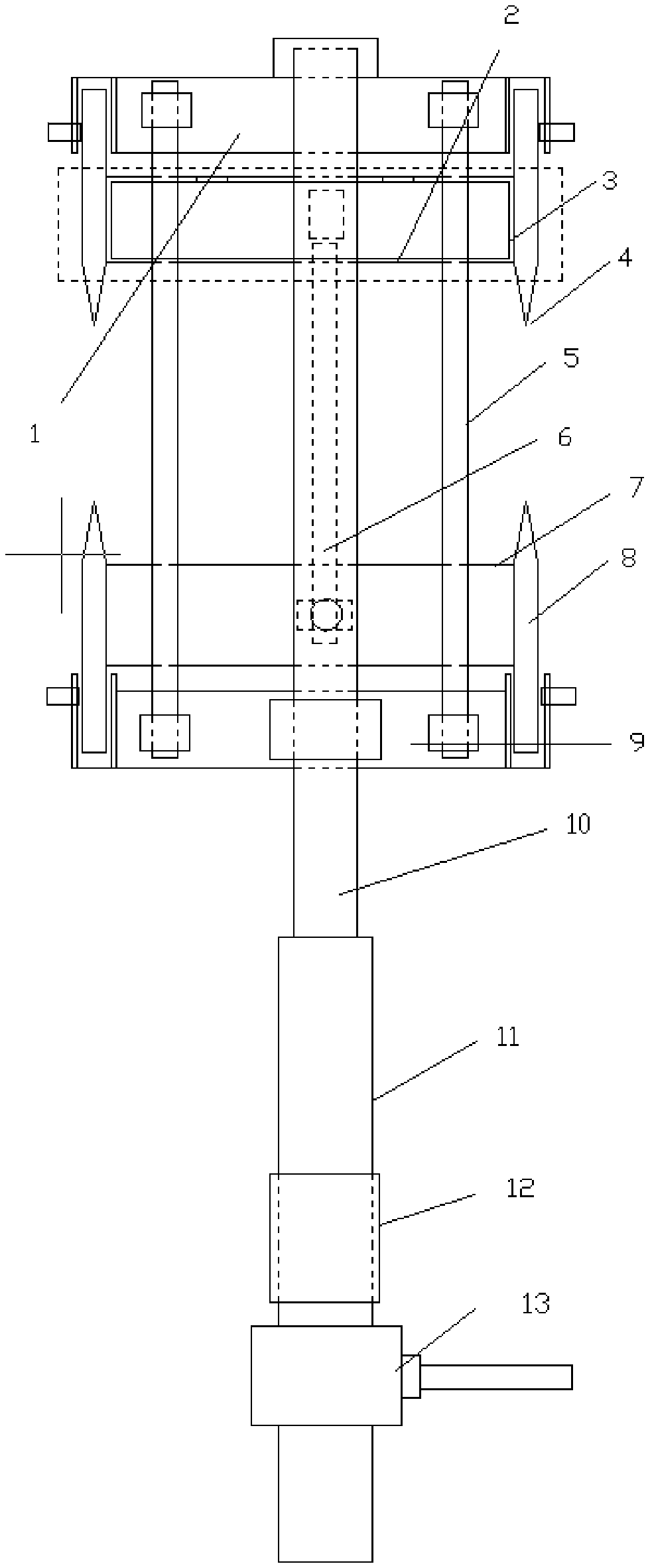

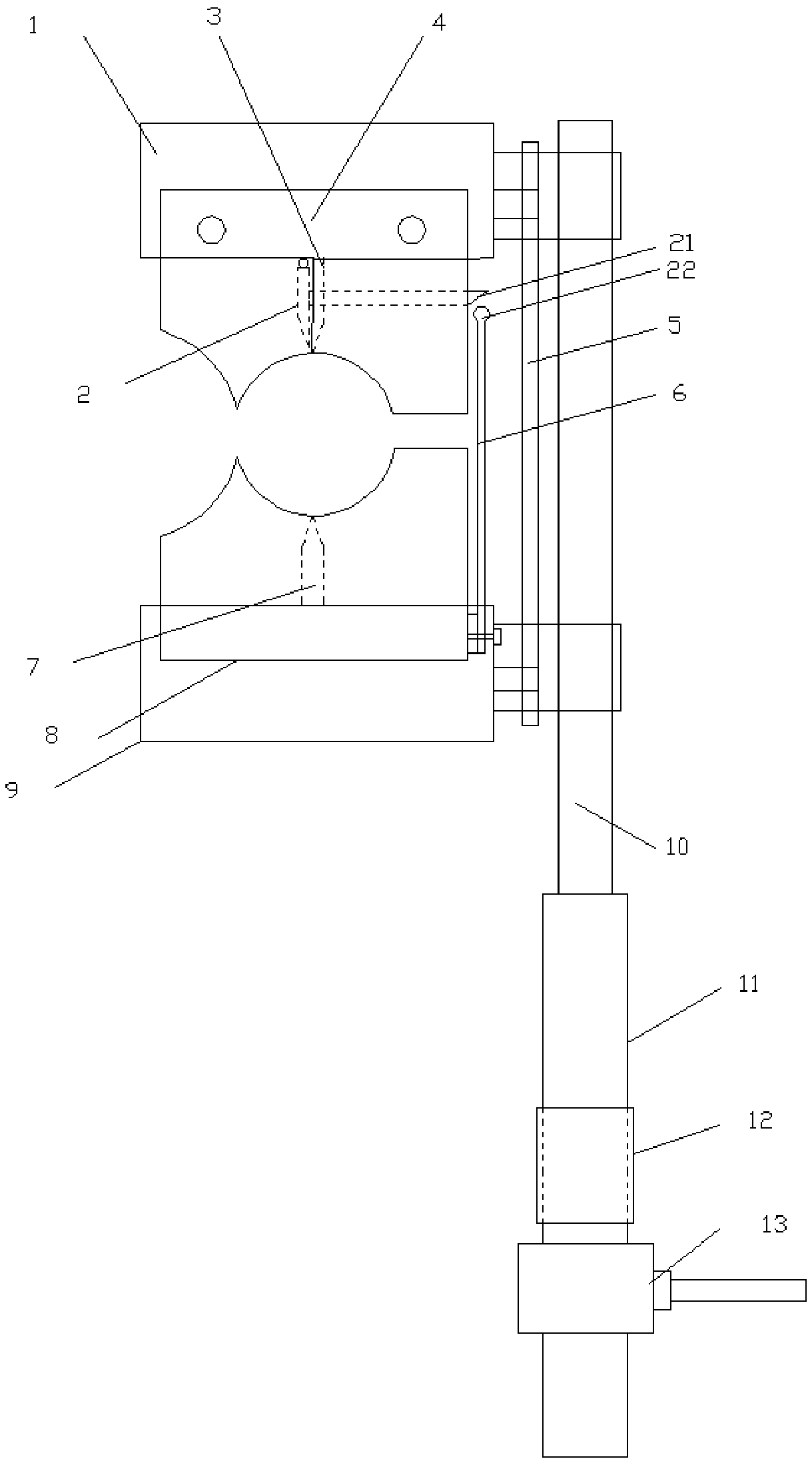

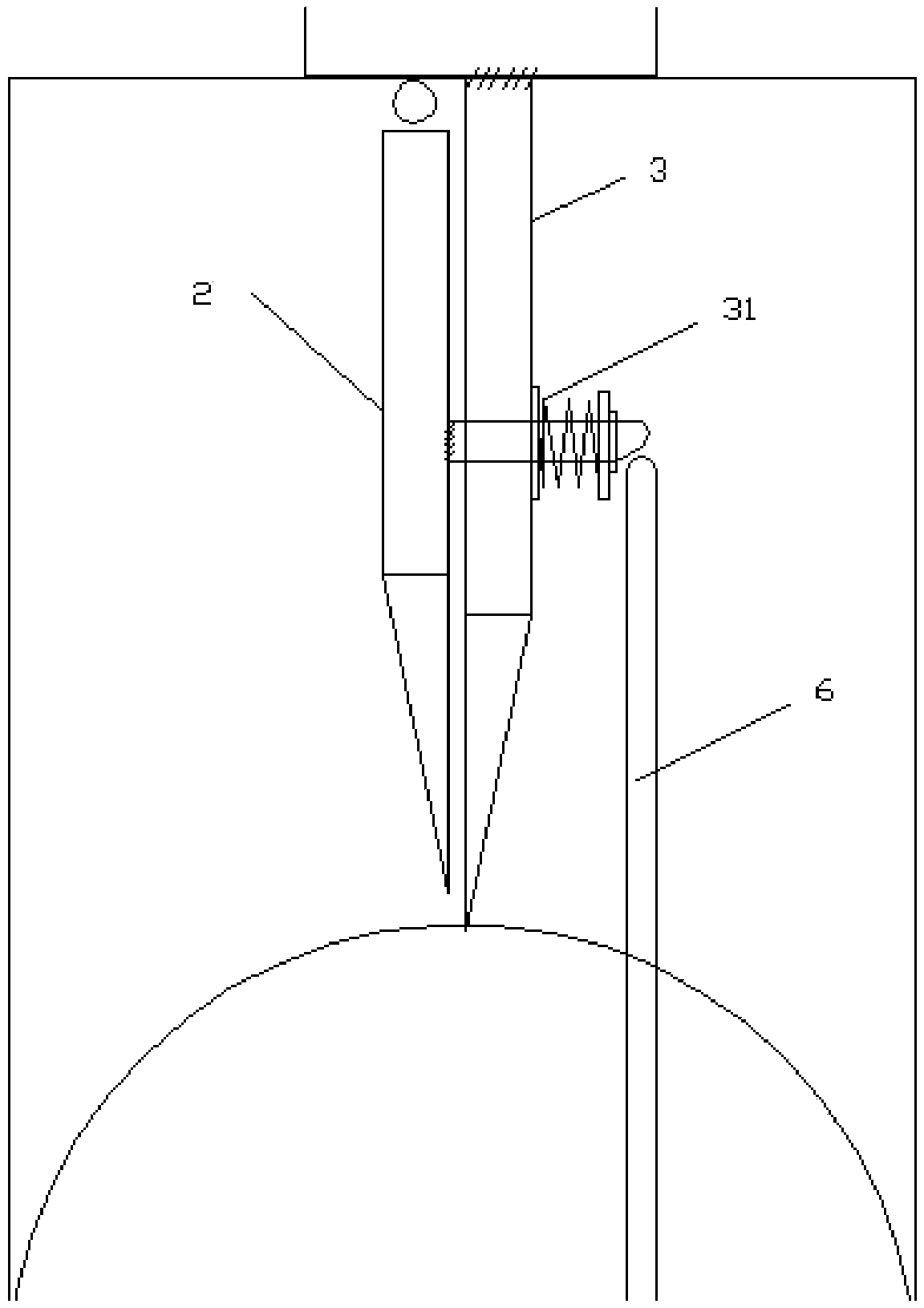

[0024] In the figure 1. Upper knife rest, 2. Push knife, 3. Upper vertical knife, 4. Upper horizontal knife, 5. Guide rod, 6. Ejector rod, 7. Lower vertical knife, 8. Lower horizontal knife, 9. Lower Knife holder, 10. fastening screw, 11. insulating rod, 12. hand-held slide tube, 13. adjustable ratchet wrench, 21. push rod, 22. glue head, 31. elastic mechanism.

[0025] A six-knife cable stripper, including a stripping device, the stripping device includes two upper and lower blade assemblies oppositely arranged, the blade assembly includes two horizontal knives for circumferential cutting and one vertical knife for linear cutting , two upper horizontal knives 4 and upper vertical knives 3 jointly constitute an upper blade assembly, and two lower horizontal knives 8 and lowe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com