Solar cell panel

A technology of solar panels and solar cells, applied in circuits, electrical components, photovoltaic power generation, etc., can solve the problems of high cost of conductive adhesive films, complicated processing, increased processing costs and time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

experiment example 1

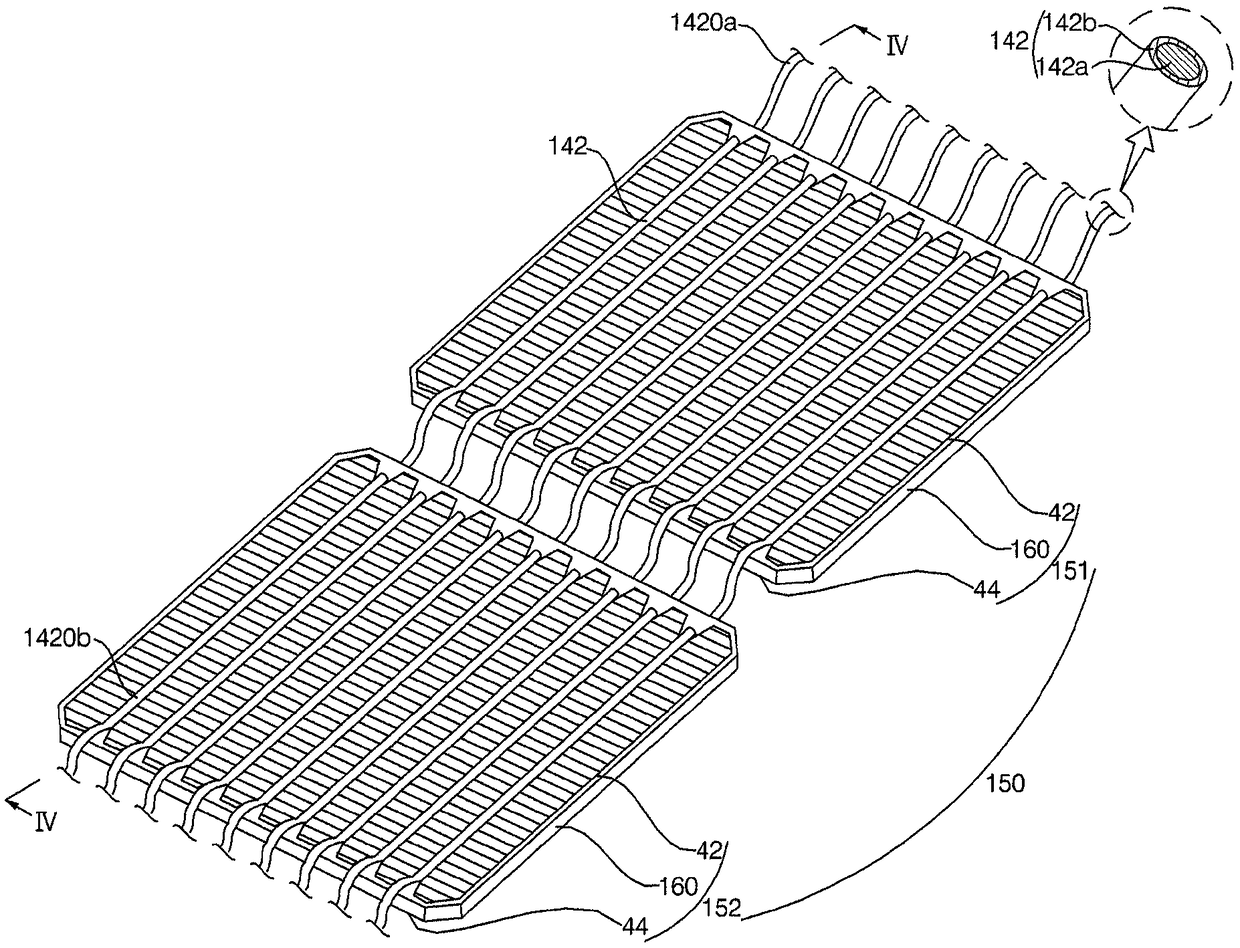

[0151] The metal electrode layer is formed by applying a low-temperature paste and heat-treating it. Low-temperature pastes include metal particles, cross-linked resins, hardeners, and solvents. The metal particles include spherical particles having a size of 0.1 to 5 um and flake-shaped particles having a long width of 2 to 10 um and a thickness of 0.2 to 5 um. In this case, relative to 100% by weight of metal particles, 80% by weight of spherical particles is included and 20% by weight of flake-shaped particles is included. The crosslinking resin is an epoxy resin, the hardener is an amine hardener, and the solvent is butyl carbitol acetate. With respect to 100% by weight of the sum of the metal particles and the cross-linked resin, 80% by weight of the metal particles, 20% by weight of the cross-linked resin, 2% by weight of the hardener, and 10% by weight solvent.

[0152] The lead wires are attached on the metal electrode layer by a wiring process that applies heat and...

experiment example 2

[0154] The pull-out strength was measured by the same method as in Experimental Example 1, except that the lead wire including the second solder layer of SnBi instead of the first solder layer was attached by the wiring process.

experiment example 3

[0156] The pull-out strength was measured by the same method as in Experimental Example 1, except that the lead wires of the third solder layer including SnIn instead of the first solder layer were attached by wiring processing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com