A method for installing steel columns for factory building expansion located at existing pipelines

An installation method and technology for steel columns, which are applied in construction, building maintenance, building construction, etc., can solve problems such as affecting the owner's production task indicators, restricting the construction progress of the project, and obstructing energy medium pipelines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

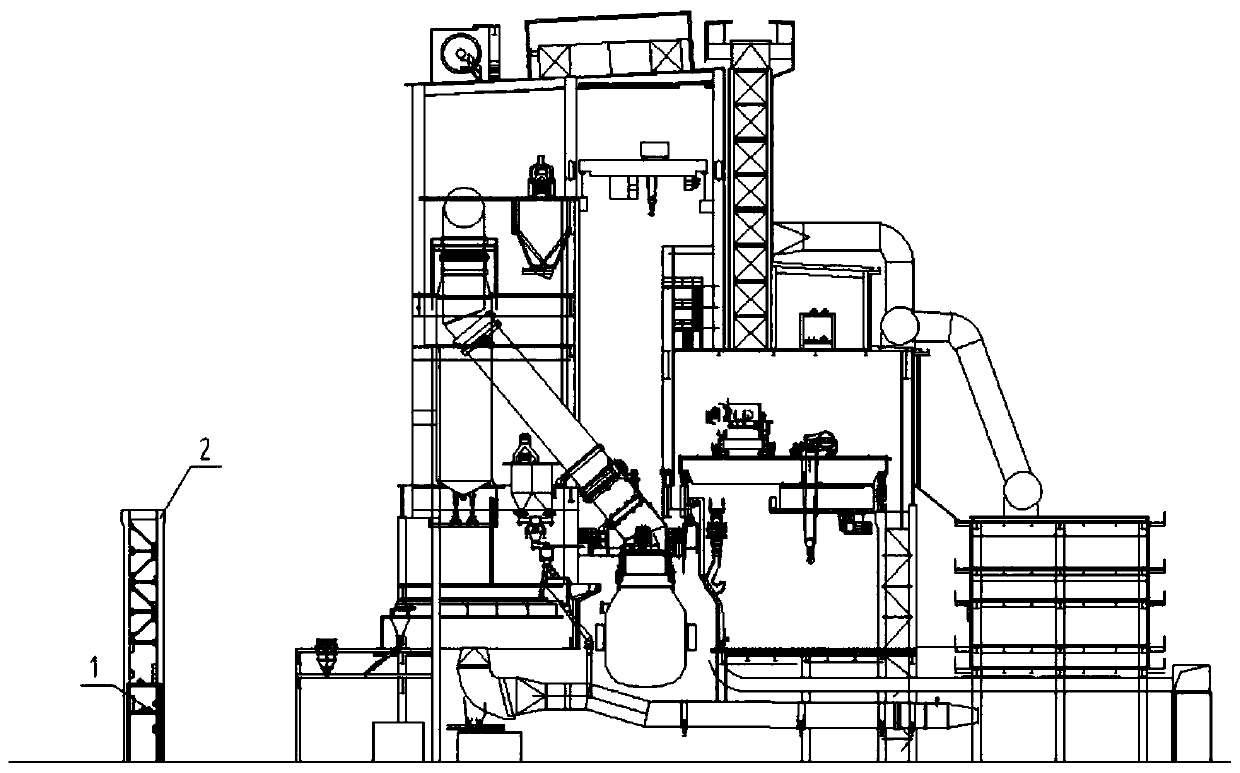

[0028] In the expansion project of a 120t steelmaking converter plant in Shandong, the installation method of the plant expansion steel column at the existing pipeline was adopted to complete the installation of the plant expansion steel column.

[0029] (1): Project overview:

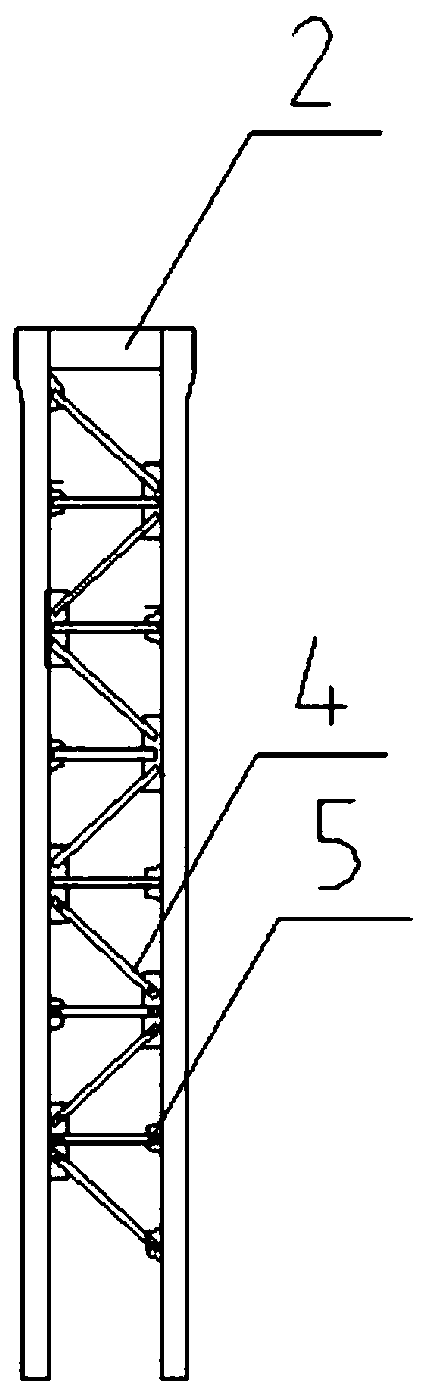

[0030] The relevant parameters of the expanded plant structure are: the maximum elevation of the latticed steel column of the expanded plant is 38.900m, the weight of the lower steel column 2 of the steel column is 44t, and the length is 27.400m; the weight of the upper steel column 3 is 14t, and the length is 12.500m m; Elevation dimension of the upper surface of the energy medium pipeline: the highest elevation is 10.000m, and the outer diameter of the energy medium pipeline is 273mm.

[0031] (2) The construction steps are:

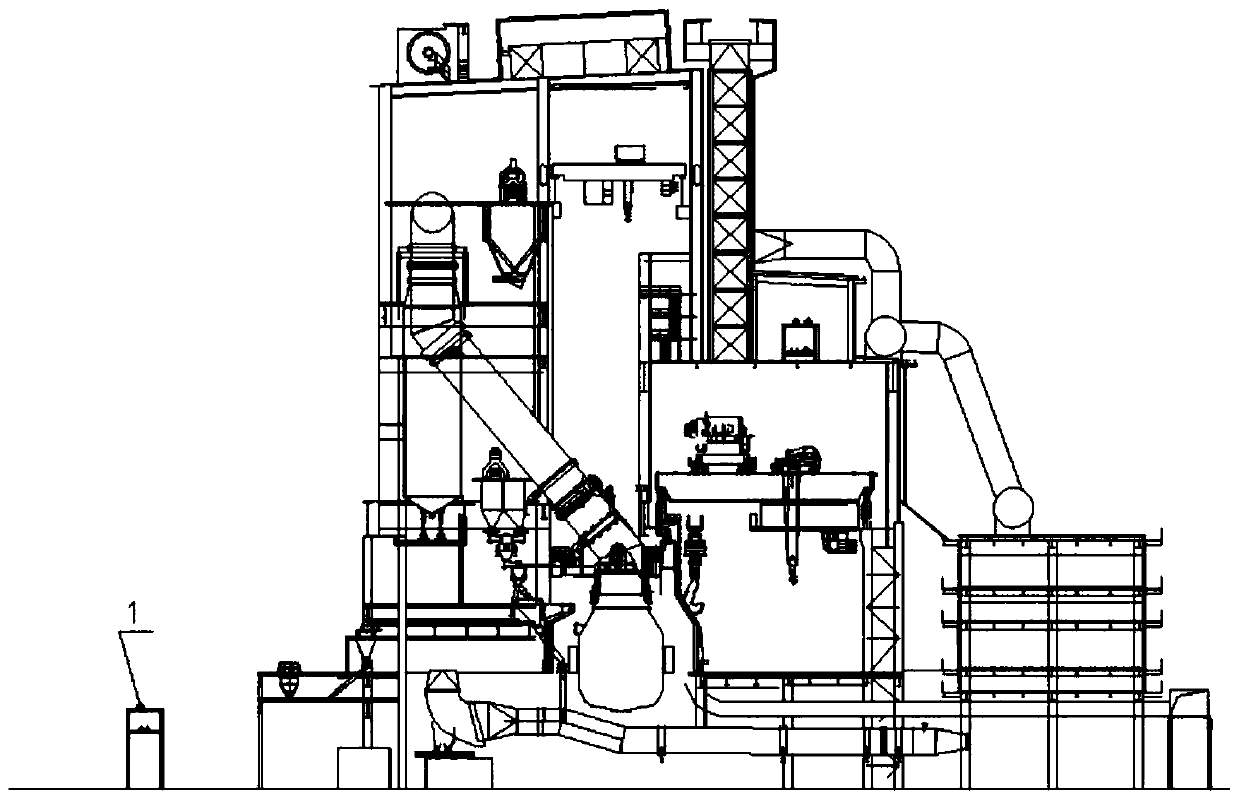

[0032] Step 1, Screening of collision points for installation of steel columns for plant expansion: (such as figure 1 shown):

[0033] 1) According to the longitudinal and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com