Sheets for mist dissipation of cooling tower and mist dissipation module

A cooling tower and defogging technology, applied in water shower coolers, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as loss, visual impact, icing, etc., and achieve the effect of reasonable structural design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The implementation of the present invention will be illustrated by specific specific examples below, and those skilled in the art can easily understand other advantages and effects of the present invention from the contents disclosed in this specification.

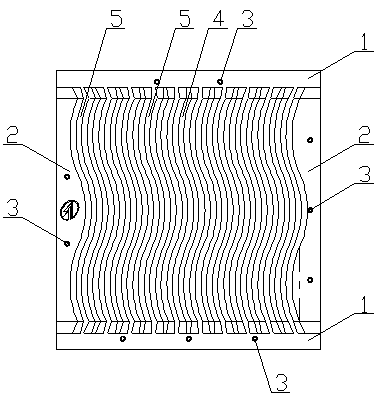

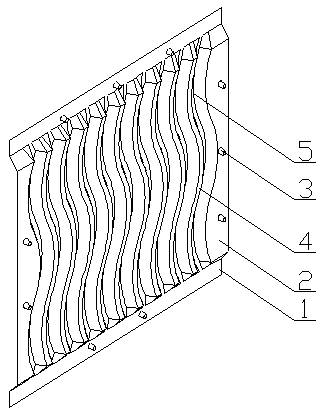

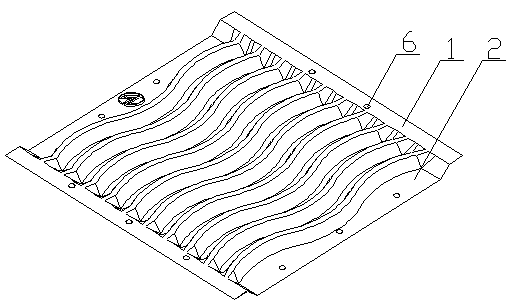

[0029] Such as figure 1 , 2 , Shown in 3: this embodiment provides a cooling tower defogging sheet, including:

[0030] Square structure sheet base, the shape of the sheet base is used to keep the length of its four sides the same, so that the cooling tower defogging sheets can be assembled into a defogging module of a specified structure;

[0031] The first assembly surface 1 located on the opposite upper side and the lower side of the sheet substrate, the first assembly surface 1 is the entire side edge part where it is located, and the first assembly surface 1 and the sheet substrate are located in the same plane ;

[0032] The second assembly surface 2 located on the opposite left and right sides of the sheet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com