Machining device of hardware parts

A processing device and hardware parts technology, applied in the field of hardware processing equipment, can solve the problems of air quality reduction, dust pollution in the working space, and the efficiency of hardware processing that affect the health of the operator, so as to improve the service life and avoid unsatisfactory drilling Accurate and avoid the effect of low air quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

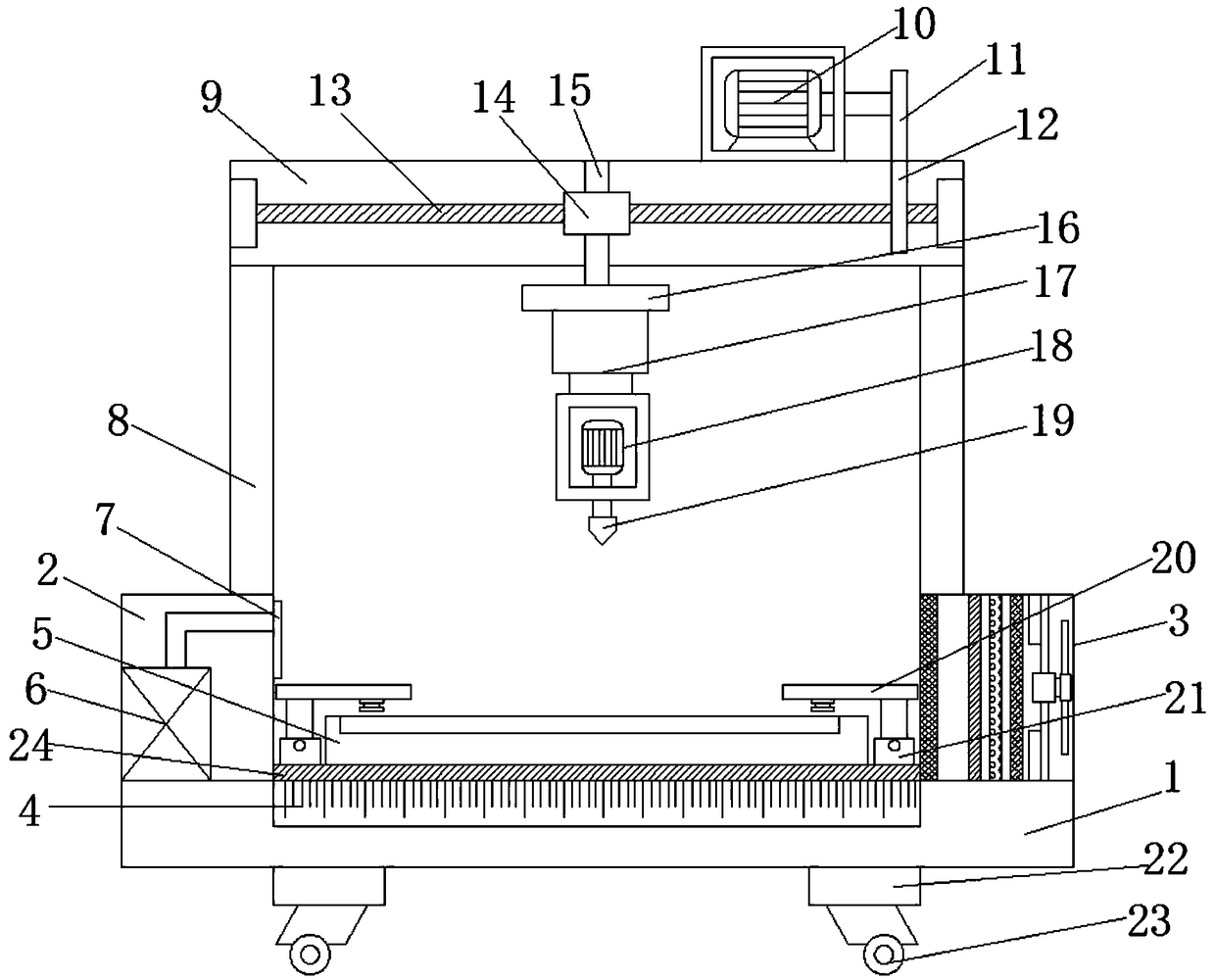

[0022] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

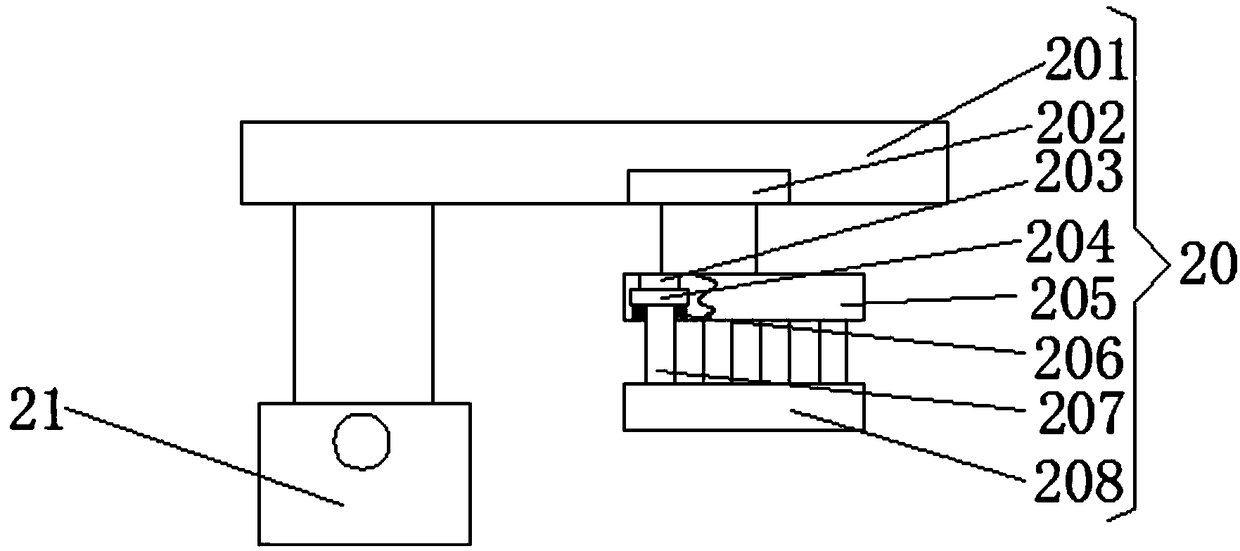

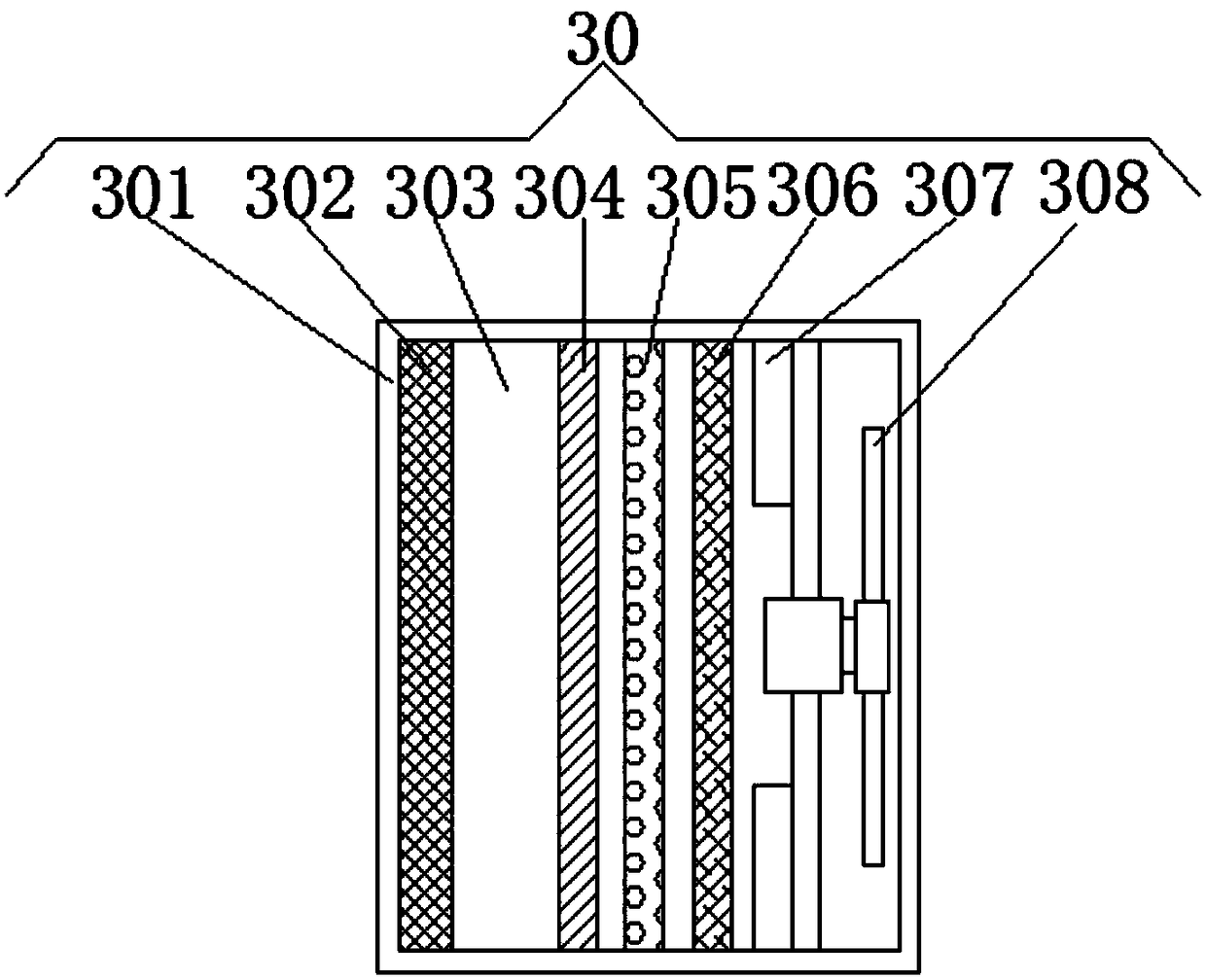

[0023] An embodiment of the present invention provides a processing device for hardware parts, such as Figure 1-3 As shown, including the base 1, the left side of the top of the base 1 is fixedly equipped with an air jet box 2, the bottom of the support column 8 is fixedly installed with the top of the air jet box 2, and the inside of the air jet box 2 is fixedly installed with a fan 6. By setting the fan 6, Driving the fan 6 can blow away the impurities produced by the hardware to a certain position during drilling, so as to avoid affecting the quality of the hardware drilling. The top of the fan 6 is provided with a nozzle 7, and one end of the nozzle 7 extends to the top of the workbench 5 On the other hand, the inside of the base 1 is fixedly equipped with a scale 4. By s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com