A signal segmentation method for real-time monitoring of drilling processing status

A processing status and real-time monitoring technology, applied in metal processing equipment, metal processing machinery parts, manufacturing tools, etc., can solve problems such as real-time impact and detection failure, so as to improve reliability, improve real-time performance, and shorten analysis and processing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

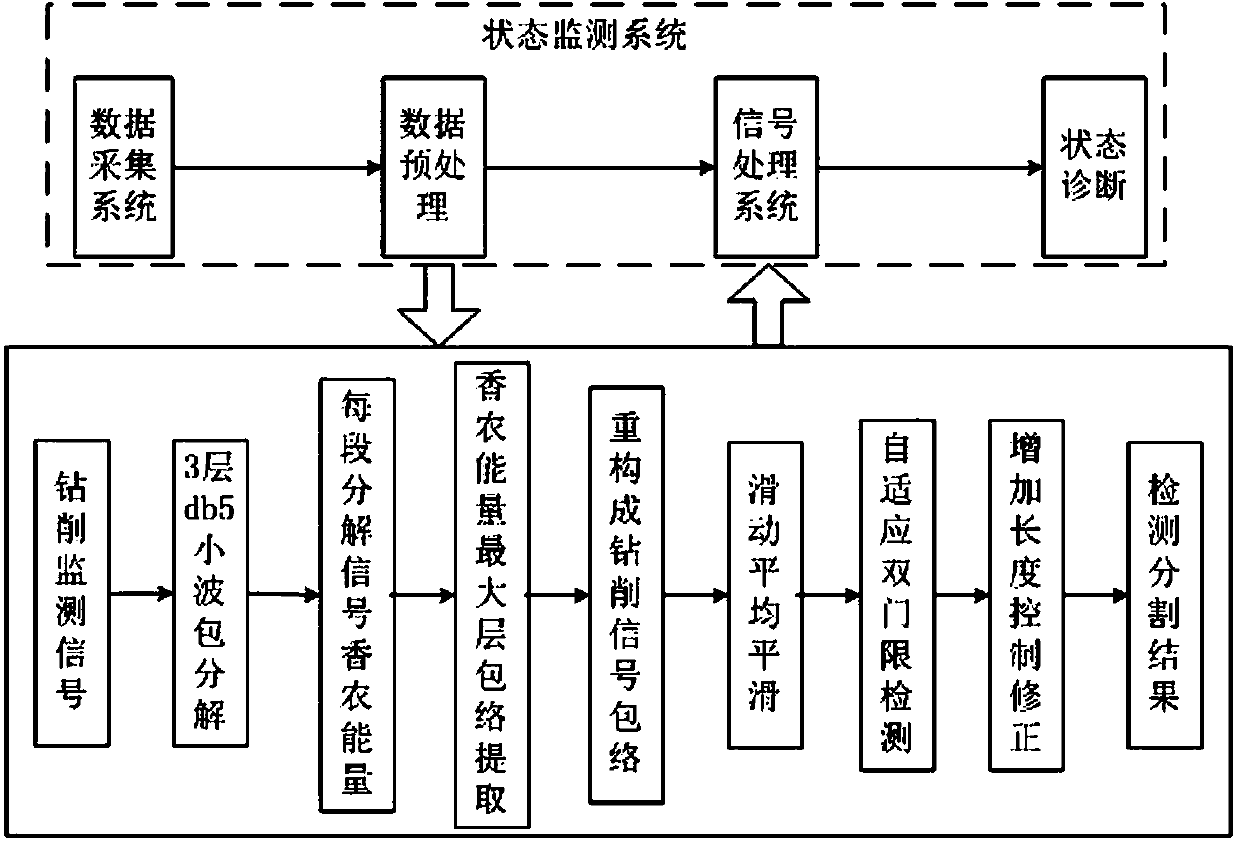

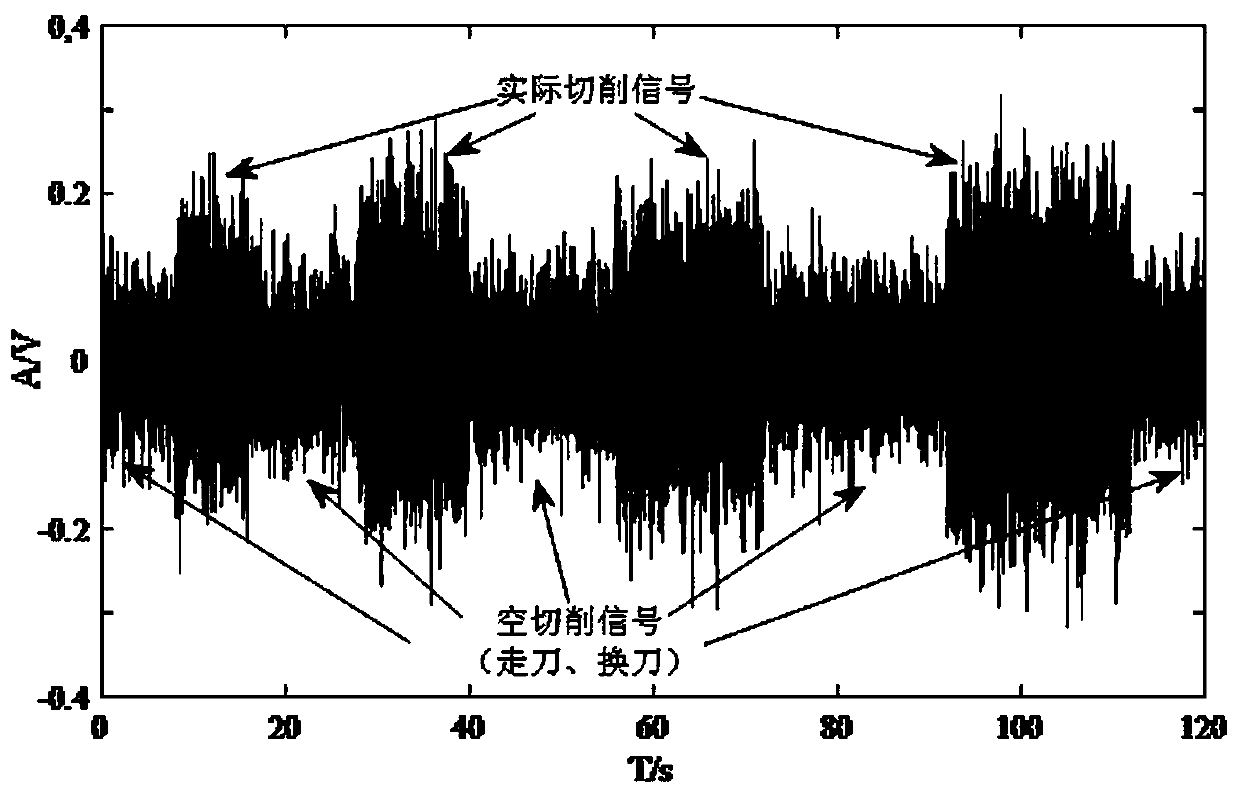

[0024] Embodiment 1, it mainly realizes the automatic detection of actual cutting (elimination of empty cutting) to select a stable signal segment representing the processing state and solve the problem of too much data in the signal processing process. The key points of the technical solution are: firstly, the wavelet packet decomposition is used for the drilling monitoring signal, and the normalized Shannon energy of each layer signal is calculated respectively; then, the Shannon envelope of the layer signal with the largest Shannon energy is reconstructed as the drilling monitoring signal Envelope; then, use the moving average algorithm to smooth the signal envelope, and realize the dual-threshold adaptive signal detection and segmentation by continuously updating the noise signal estimation in real time; finally, calculate the theoretical length of the cutting signal segment according to the drilling processing parameters, and introduce the theoretical length into the detect...

Embodiment 2

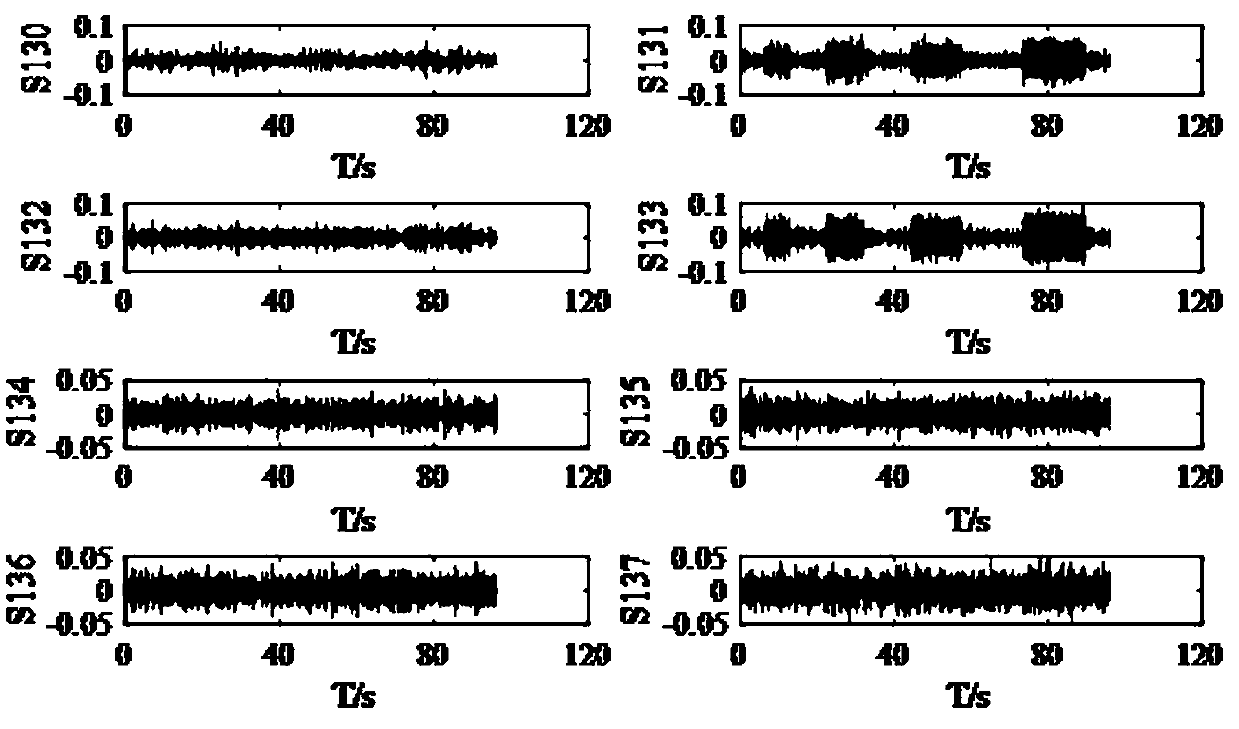

[0025] Embodiment 2, the wavelet packet decomposition is to decompose the drilling monitoring signal X(t) using db5 wavelet 3 layers, and decompose the signal into 8 different frequency bands: s130, s131,..., s137, wavelet basis function and decomposition layer The number is determined by comparing the signal segmentation effect through experiments. refer to Figure 1 to Figure 8 , all the other are with embodiment 1.

Embodiment 3

[0026] Embodiment 3, the normalized Shannon energy of each layer signal after the calculation is decomposed, and the Shannon envelope of the layer signal with the largest Shannon energy is reconstructed as the drilling monitoring signal envelope. The calculation process is: first, for s130, s131 ,...,s137 for normalization x(i)=s13i norm =s13i / max(|s13i|); Then, calculate its Shannon energy E(i)=-x for the normalized signal 2 (i)log[x 2 (i)]; finally, obtain the Shannon envelope p(i)=[E(i)-M(E(i))] / S(E(i)) of the signal, M(E(i)) is Shannon energy mean, S(E(i)) Shannon energy variance. refer to Figure 1 to Figure 8 , and the rest are the same as the above-mentioned embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com