Mobile marine micro-plastic recovery vessel and marine micro-plastic recovery method thereof

A microplastic and mobile technology, applied in the field of ships, can solve the problems of not being able to collect microplastics quickly and effectively, reducing the effective water area, and prolonging the collection time, so as to increase the effective water area, enhance the endurance, and reduce the collection time. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to better explain the present invention and facilitate understanding, the present invention will be described in detail below through specific embodiments in conjunction with the accompanying drawings.

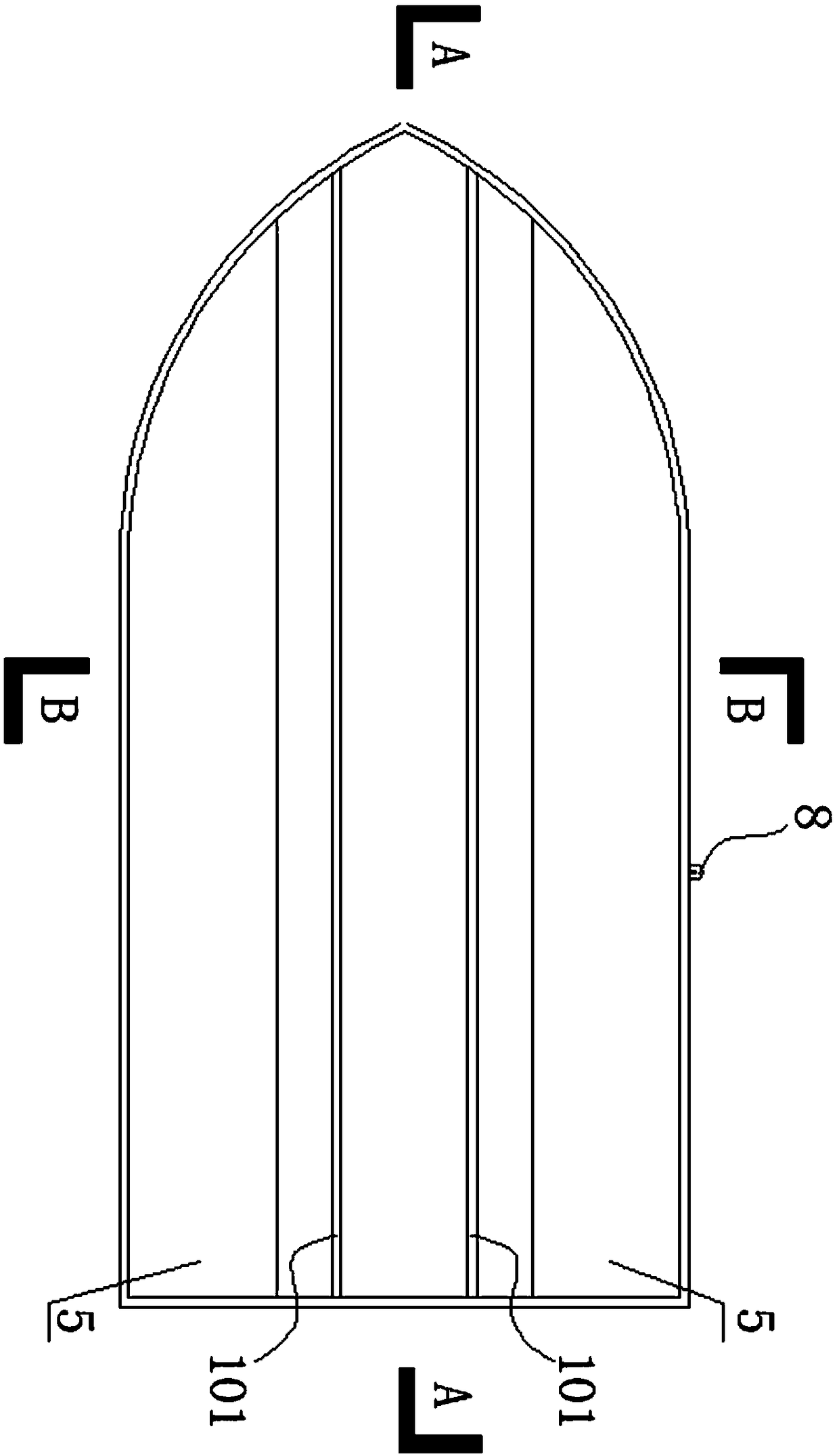

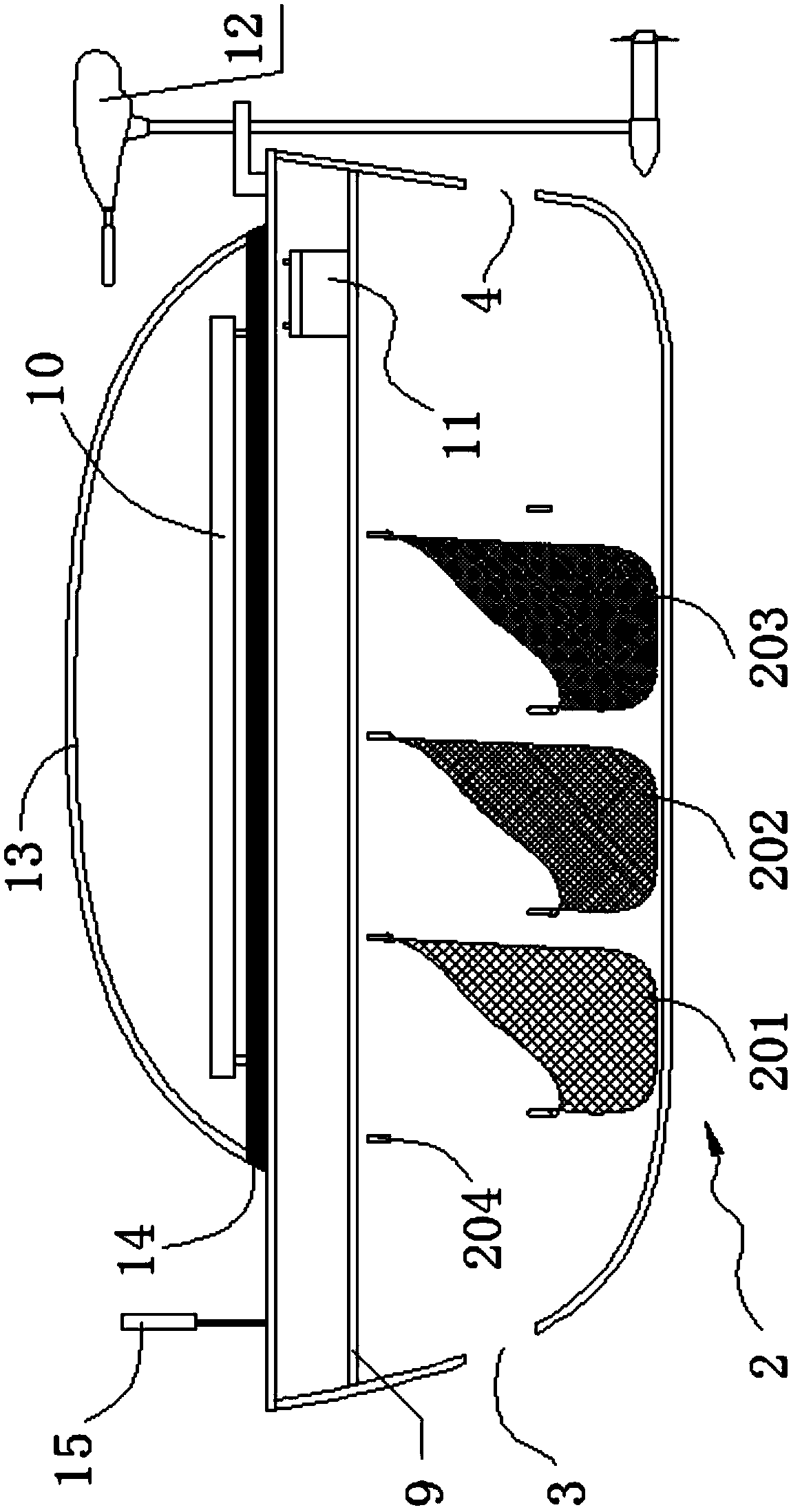

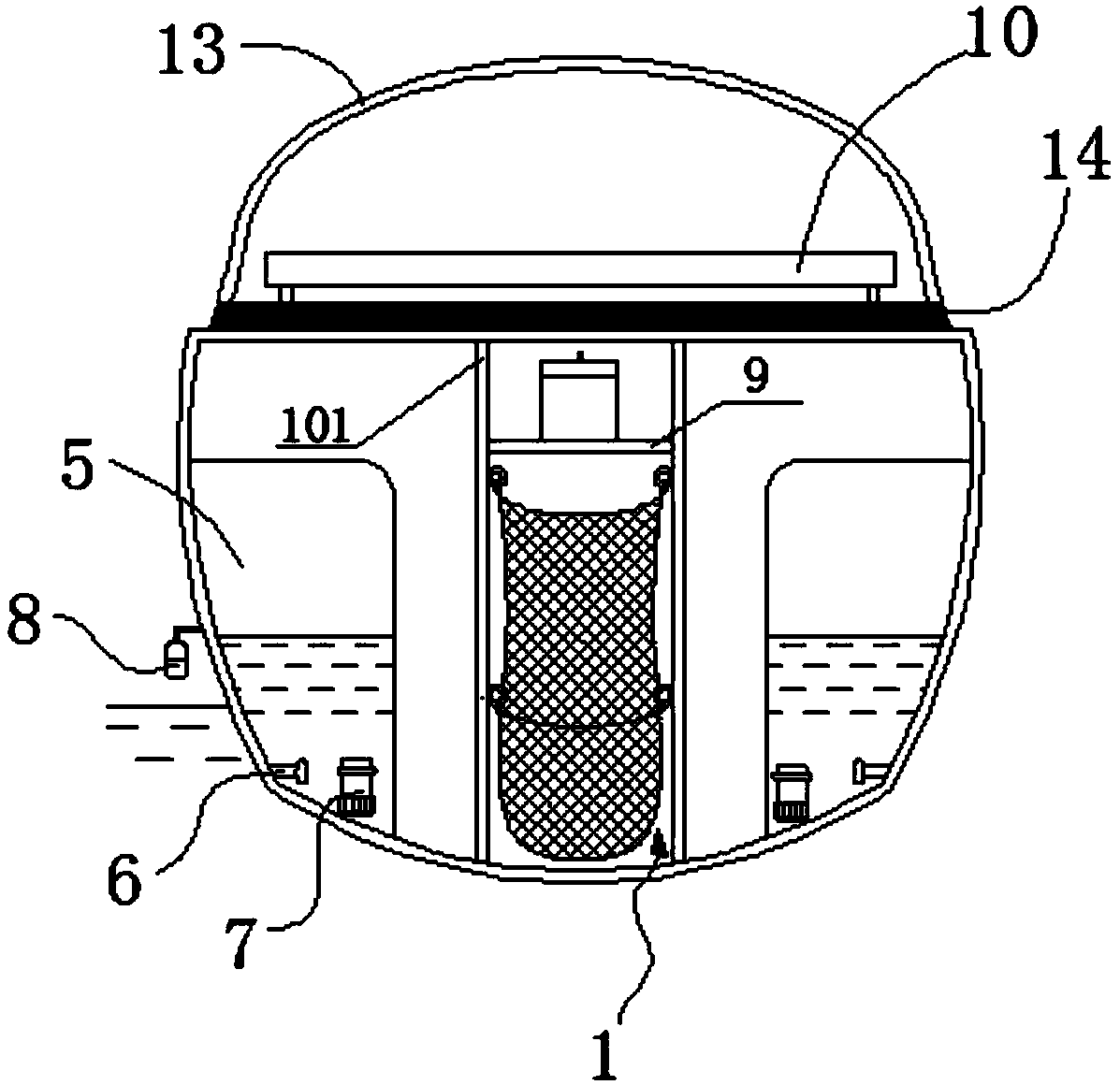

[0051] Such as Figure 1-4 Shown: two partitions 101 are vertically arranged in the cabin, and a water passage 1 for running water to enter and exit is formed between the partitions 101, and the water passage 1 is an airtight structure to prevent water leakage. The bow and the stern are respectively provided with a water inlet 3 and a water outlet 4, which communicate with the two ends of the water passage 1 respectively. The microplastic recycling assembly 2 is a multi-stage filter mesh bag, and its number is preferably set to 3, which are respectively the first mesh bag 201, the second mesh bag 202 and the third mesh bag 203, and the average pore size decreases successively. The average aperture of the first filter bag 201 is 10-20mm, the average aperture of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com