Crane flipping process

A process and crane technology, applied in cranes, load hanging components, portable lifting devices, etc., can solve the problems of high cost, large labor input, complex construction procedures, etc., achieve less machinery, optimize construction procedures, reduce costs and human effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings, and this embodiment does not constitute a limitation to the present invention.

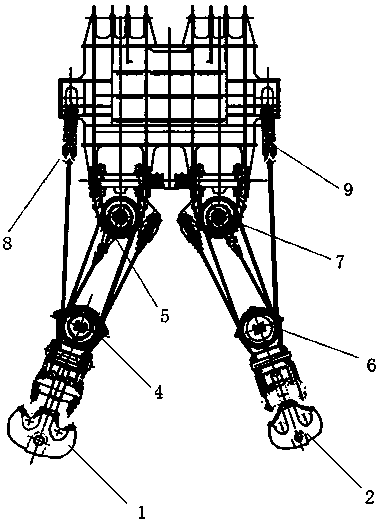

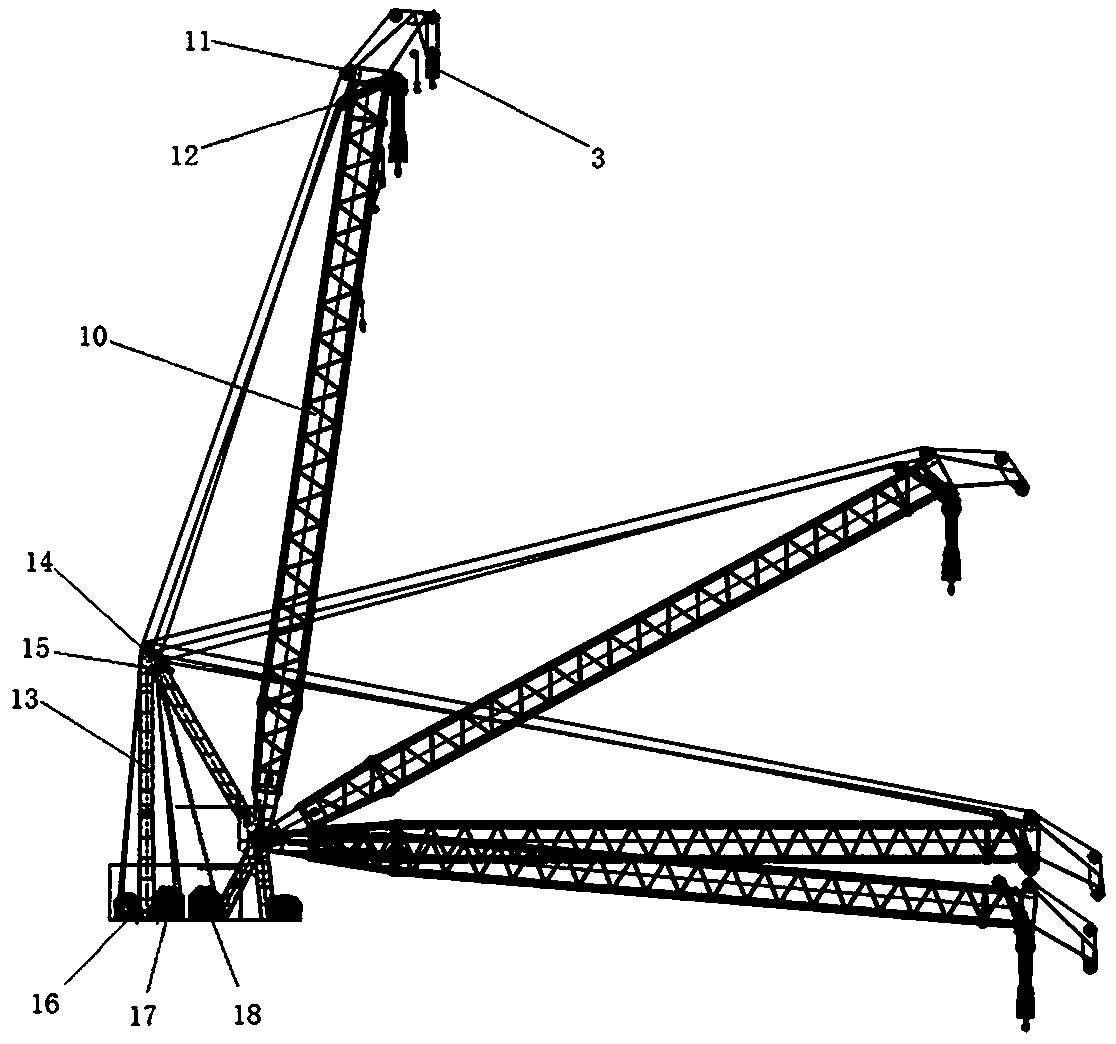

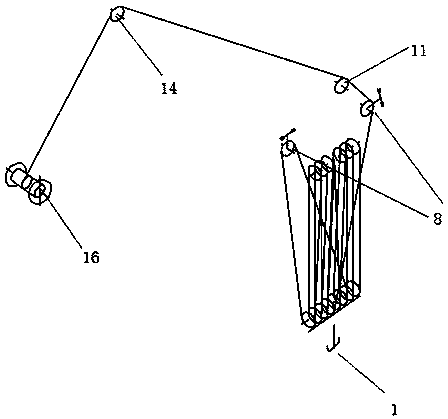

[0033] A crane turnover process, including a vertical turnover process and a horizontal turnover process, including a first main hook 1, a second main hook 2, an auxiliary hook 3, a first movable pulley 4, a first fixed pulley 5, a second movable pulley 6, a first Two fixed pulleys 7, the first swing pulley block 8, the second swing pulley block 9, the jib frame 10, the first jib frame redirection pulley 11, the second boom frame redirection pulley 12, the herringbone frame 13, the first herringbone frame modification Redirecting pulley 14, second reversing pulley 15 of herringbone frame, first winch 16, second winch 17, third winch 18, single pile 19, lifting lug 20, turning lug 21, first wire rope 22, lifting beam 23 , the second steel wire rope 24, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com