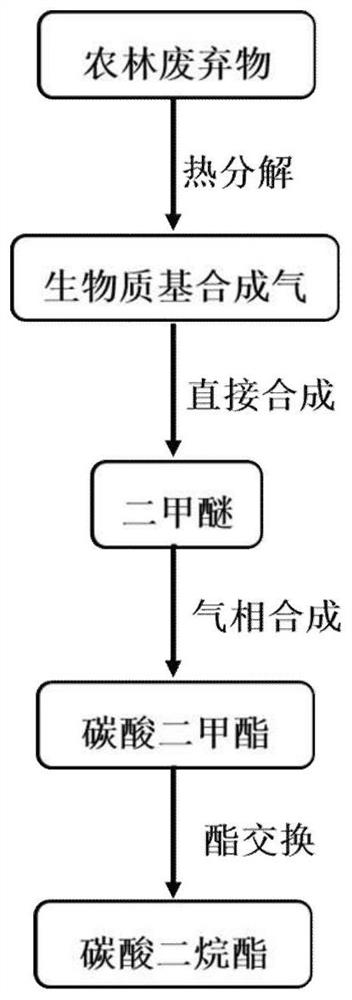

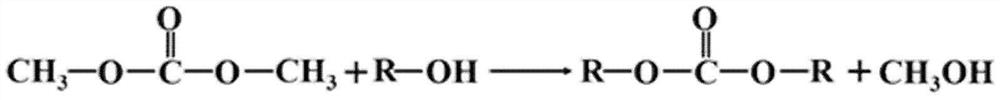

A method for synthesizing dialkyl carbonate from biomass-based synthesis gas

A technology for dialkyl carbonate and dimethyl carbonate is applied in the field of biomass-based synthesis gas to synthesize dialkyl carbonate, and can solve the problems of high corrosiveness of catalyst equipment, highly toxic dimethyl sulfate, and high operational safety requirements, Achieve the effect of scientific and environmentally friendly synthesis method, low production cost, and reduction of environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) Preparation of biomass-based syngas

[0028] Put 100g of wood chips made into pellets into the gasifier, first control the temperature of the drying layer of the gasifier to 200°C, and dry the wood chips for 2.5 hours; then adjust the temperature for pyrolysis layer temperature to 500°C, and then pyrolyze the wood chips 1.5h; finally, the sawdust enters the combustion layer at a temperature of 900°C, and the steam of the gasification agent is introduced into the combustion layer of the gasifier at a rate of 1g / min. The main components of syngas are: 35% H 2 , 38% CO, 11% CO 2 , 15%H 2 O.

[0029] The crude synthesis gas is reformed to H through a steam shift reaction unit 2 The molar ratio to CO is 1.4, iron is used as the catalyst, the pressure is 0.8MPa, and the reaction temperature is 250°C; then the gas is purified into a methanol solution at -53°C to absorb CO 2 , to collect syngas.

[0030] 2) Synthesis of dimethyl ether

[0031] The first is the prepara...

Embodiment 2

[0042] 1) Preparation of biomass-based syngas

[0043] Put 150g of wood chips made into pellets into the gasifier, first control the temperature of the drying layer of the gasifier to 180°C, and dry the wood chips for 2.5 hours; then adjust the temperature for pyrolysis layer temperature to 400°C, and then pyrolyze the wood chips 1.5h; finally, the sawdust enters the combustion layer at a temperature of 800°C, and the steam of the gasification agent is introduced into the combustion layer of the gasifier at a rate of 1.5g / min, and the gas from the gasification furnace is recovered to make biomass crude syngas The main components of crude synthesis gas are: 35% H 2 , 30% CO, 20% CO 2 , 15%H 2 O.

[0044] The crude synthesis gas is adjusted by the steam shift reactor to adjust the H 2 The ratio to CO is 1.3, iron is used as the catalyst, the pressure is 0.8MPa, and the reaction temperature is 250°C; then the gas is passed into the methanol solution at -53°C to absorb CO 2 ,...

Embodiment 3

[0057] 1) Preparation of biomass-based syngas

[0058] Put 120g of wood chips made into pellets into the gasifier, first control the temperature of the drying layer of the gasifier to 230°C, and dry the wood chips for 2.5 hours; then adjust the temperature for pyrolysis. The temperature of the layer is 550°C, and then pyrolyze the wood chips 1.5h; finally, the wood chips enter the combustion layer at a temperature of 850°C, and the steam of the gasification agent is introduced into the combustion layer of the gasifier at a rate of 1.2g / min, and the gas from the gasification furnace is recycled to make biomass crude syngas. The main components of crude synthesis gas are: 36%H 2 , 33% CO, 19% CO 2 , 12%H 2 O.

[0059] The crude synthesis gas is adjusted by the steam shift reactor to adjust the H 2 The ratio to CO is 1.5, iron is used as the catalyst, the pressure is 0.8MP a, and the reaction temperature is 250°C; then the gas is passed into the methanol solution at -53°C to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com