Ignition driving circuit

A driving circuit and resistor technology, applied in logic circuit interface devices, logic circuit connection/interface layout, electrical components, etc., can solve the problem that the gate source cannot maintain the conduction state at the moment of conduction, the ignition system malfunctions, and the saturation conduction state To avoid problems such as large pressure drop in the tube, to increase the anti-interference ability and solve the matching problem

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

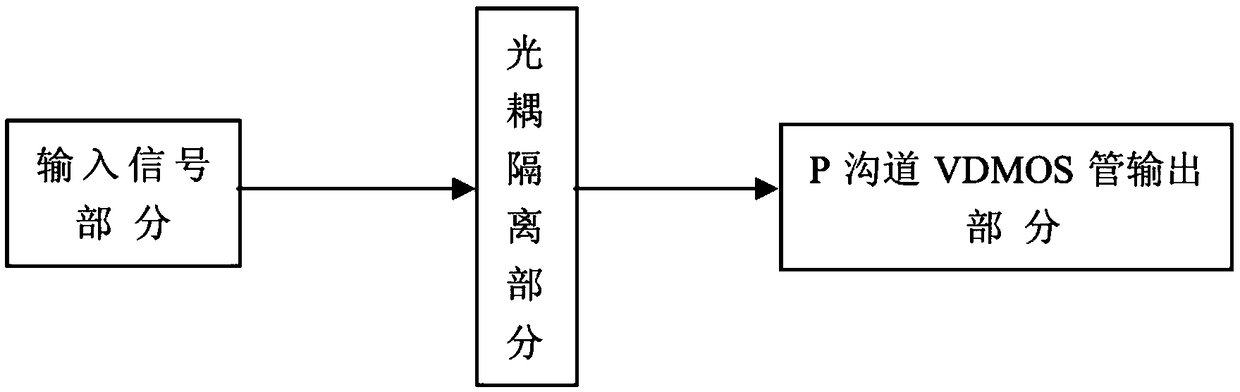

[0025] The principle block diagram of the ignition drive circuit of the present invention is as figure 1 shown. The input signal of the circuit passes through the resistor R1 to control the current flowing into the optocoupler. When the current is large enough, the light-emitting tube inside the optocoupler emits light, and the photosensitive tube of the optocoupler is controlled to conduct. The signal ground of the input terminal is separated from the ground wire of the isolated output to prevent interference signals from being transmitted to the rear stage through the ground wire.

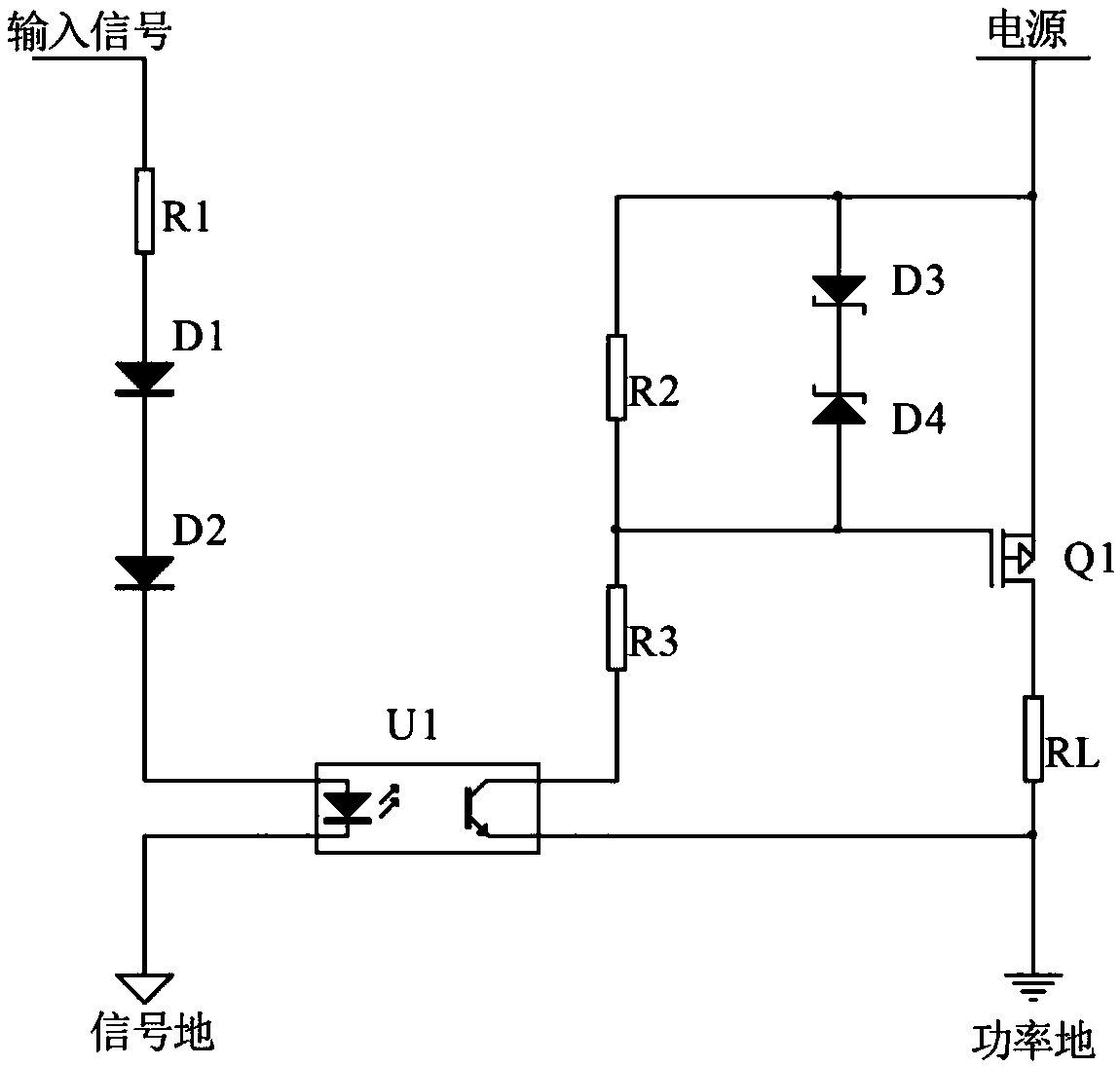

[0026] figure 2 It is the schematic diagram of the ignition drive circuit. The circuit is mainly composed of an input drive part, an optocoupler isolation part, and a P-channel VDMOS tube output part. The OLI series optocoupler is used for electrical isolation between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com