Small-size oat forage grass filament rubbing machine

A kind of oatmeal, small-scale technology, applied in agricultural machinery and tools, cutting equipment, applications, etc., can solve the problems of poor silk kneading effect of forage kneading machine, large model, expensive price, etc., to achieve good kneading effect, machine The effect of small size and cheap price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] Provide specific embodiments below in conjunction with accompanying drawings.

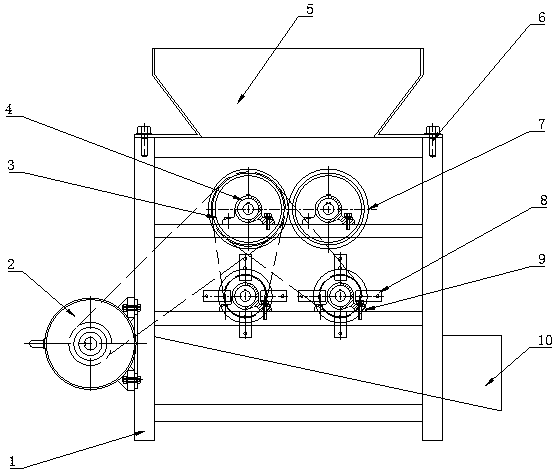

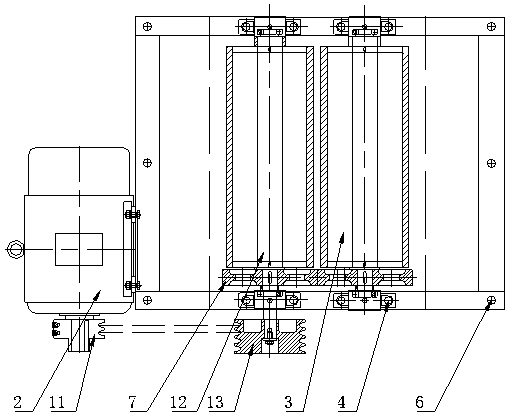

[0012] A small-sized oat forage kneading machine disclosed by the present invention mainly consists of a frame 1, a motor 2, a squeeze roller 3, a feeding port 5, a transmission gear 7, a crushing knife 8, a discharge port 10, and a center of the squeeze roller. Shaft 12 is composed. Specific as figure 1 and figure 2 shown. In the working process, the oat forage plants harvested from the field are fed into the kneading machine from the feeding port 5. After the motor 2 is connected, the power is transmitted from the motor pulley 11 to the extrusion roller drive pulley 13 through the belt drive, driving The transmission gear 7 on the central shaft 12 of the extrusion roller is driven, and the opposite rotation of the two groups of extrusion rollers 3 is realized through a set of meshed transmission gears, wherein the left side rotates clockwise and the right side rotates counterclockwise,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com