Controllable and constant-temperature tea leaf fermentation machine

A technology of tea fermentation machine and constant temperature, which is applied in the direction of tea treatment before extraction, can solve problems such as difficulty and difficulty in controlling the uniformity of temperature and humidity, and achieve the effects of uniform humidity, prevention of dry burning, and uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in combination with specific embodiments. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

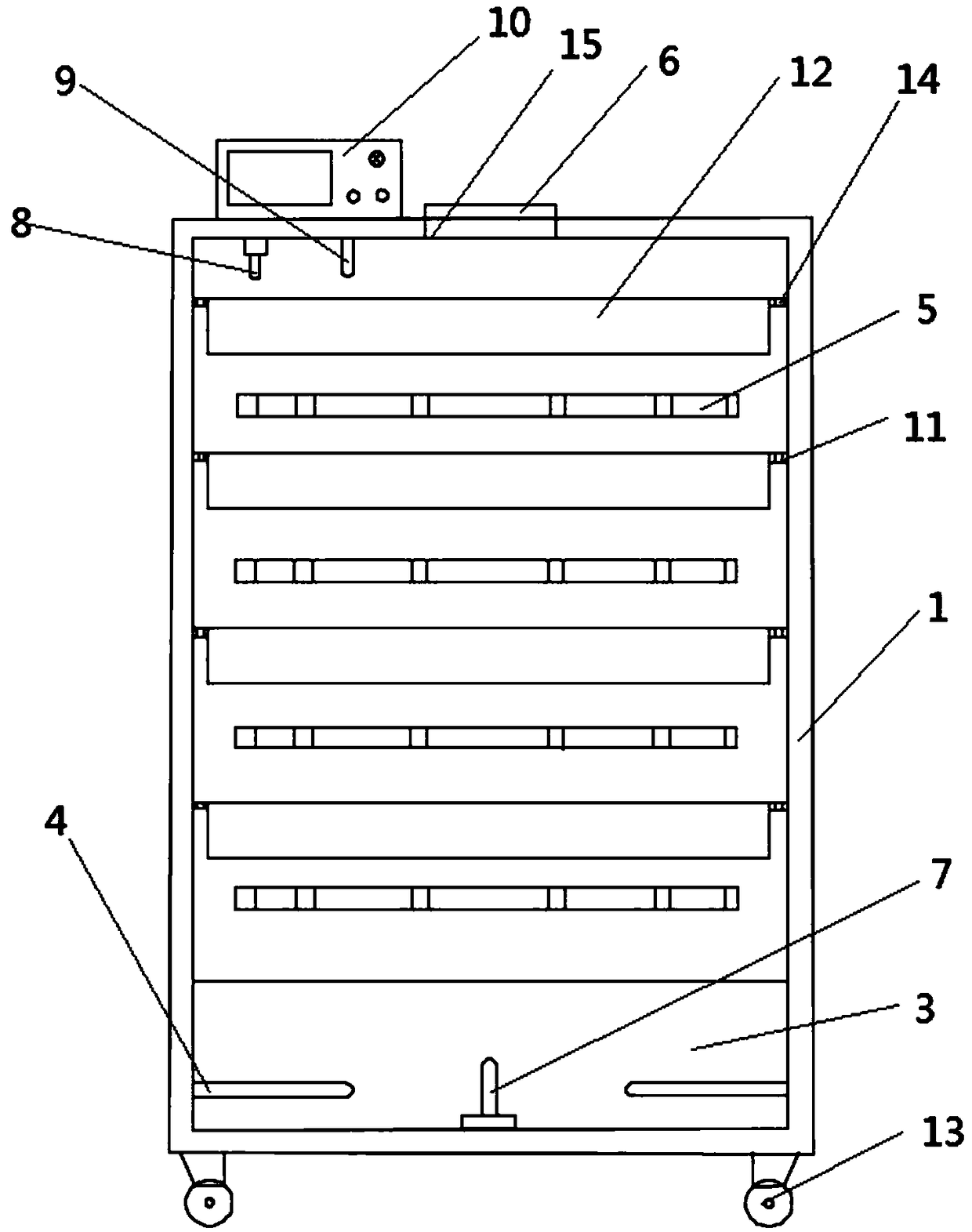

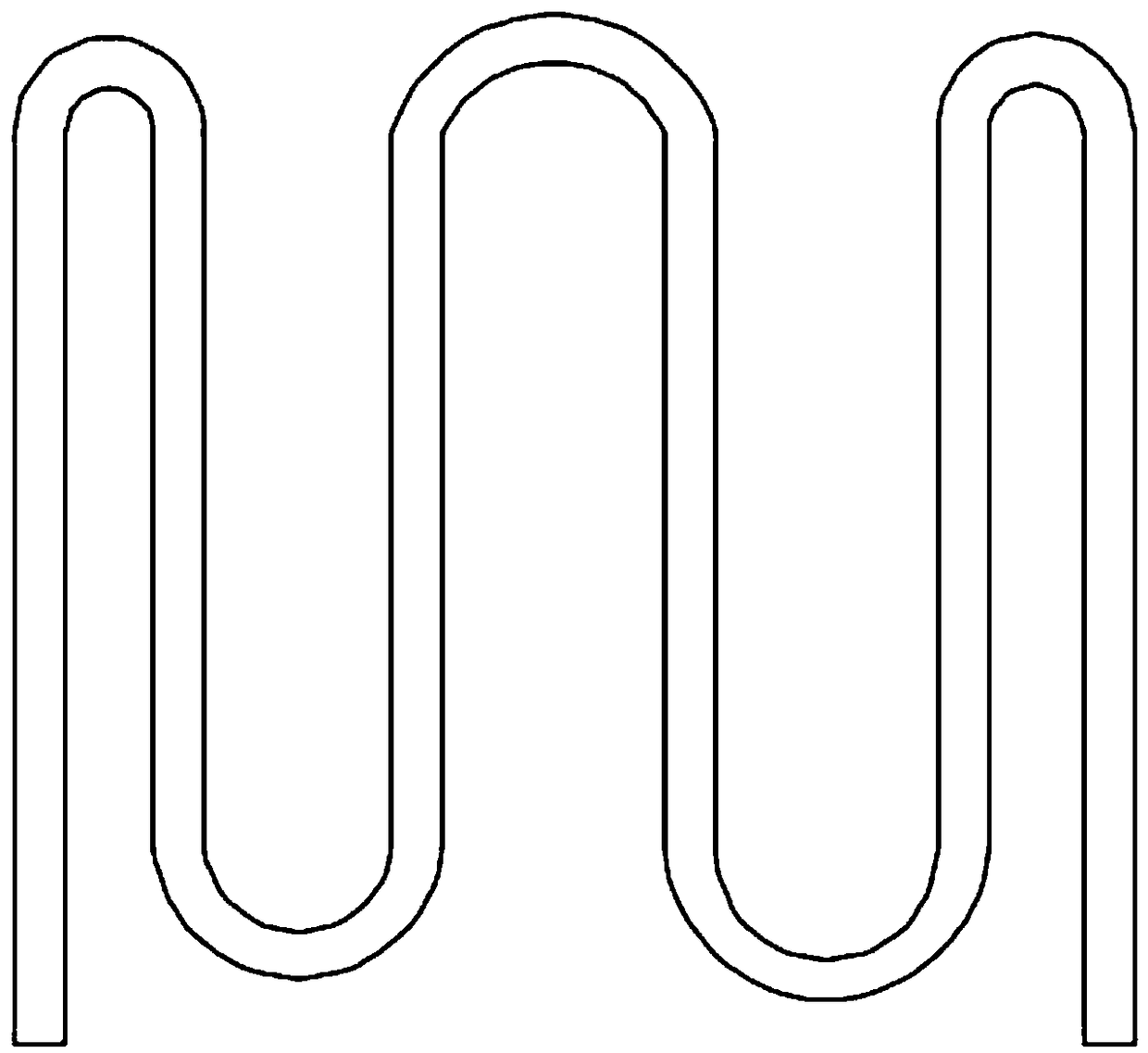

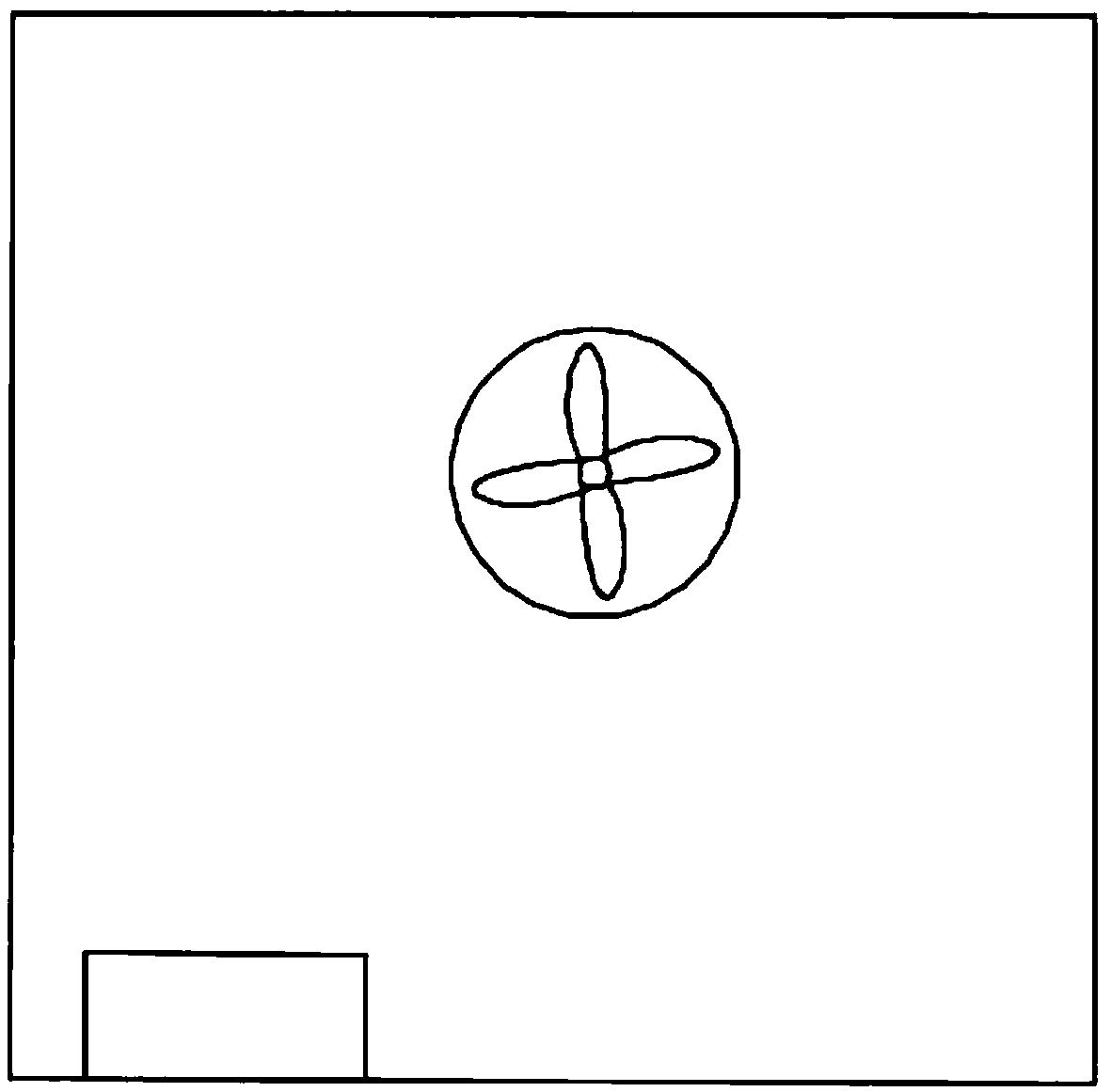

[0026] Such as Figure 1~4 As shown, the controllable constant temperature tea fermentation machine is characterized in that it includes a chassis 1, a chassis door 2, a water tank 3, a steam heating pipe 4, a greenhouse heating pipe 5, a diversion fan 6, a water level sensor 7, and a temperature sensor 8. Humidity sensor 9, controller 10; the left and right ends of the cabinet are provided with sieve plate installation positions 11 for placing the sieve plate 12, and each of the four corners of the bottom of the cabinet is provided with a pulley 13, which can facilitate fermentation The machine moves, and the box is in a square shape; the sieve plate installation position 11 is provided with a long through hole 14 for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com