A kind of control method of food processor

A technology of a food processing machine and a control method, which is applied in the direction of kitchen utensils, household utensils, applications, etc., can solve problems such as the distance deviation between the magnet and the sensor, sensor failure, and the machine cannot control the opening and closing of the cup lid, so as to avoid conversion errors, The effect of ensuring reliability and preventing hand pinch phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

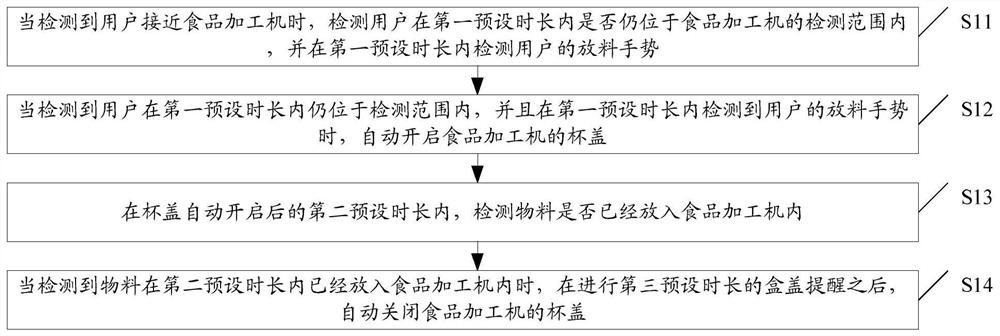

[0048] A control method for a food processing machine, such as figure 1 As shown, the method may include S11-S14:

[0049] S11. When it is detected that the user is approaching the food processor, detect whether the user is still within the detection range of the food processor within the first preset time period, and detect the user's discharging gesture within the first preset time period.

[0050] Optionally, in an initial state, the lid of the food processor is closed and can be opened manually.

[0051] In the embodiment of the present invention, the initial position of the food processing machine is set to the closed position, that is, it is in the closed state, and the user can manually open the cover, which ensures that even if the automatic opening of the machine cannot work due to sensor failure and other reasons, the user can also manually open the cover. cover to ensure reliable operation of the machine.

[0052] In the embodiment of the present invention, after ...

Embodiment 2

[0067] In this embodiment, on the basis of the first embodiment, a power storage circuit is set in the food processor.

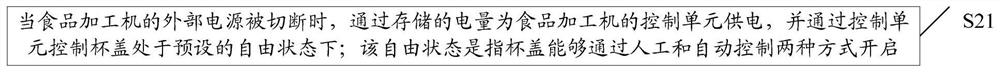

[0068] Optionally, the food processor has a power storage function; as figure 2 As shown, the method may also include S21:

[0069] S21. When the external power supply of the food processor is cut off, the stored electricity is used to supply power to the control unit of the food processor, and the control unit controls the cup cover to be in a preset free state; the free state means that the cup cover can pass through the There are two ways of manual and automatic control.

[0070] In the embodiment of the present invention, when the power is suddenly cut off during the working process of the machine, because the cup lid is in a locked state in order to prevent the user from opening the lid by mistake during work, at this time the power is suddenly cut off, and the user cannot timely remove the residual materials in the machine. Cleaning, if left for a l...

Embodiment 3

[0074] On the basis of the second embodiment, this embodiment provides a solution to the circuit of the food processor when the food processor is suddenly powered off.

[0075] Optionally, the method may also include:

[0076] When it is detected that the external power supply of the food processor is cut off, the control unit controls circuits other than the circuit for opening and closing the cup lid to be in a preset low power consumption state.

[0077] In the embodiment of the present invention, the entire circuit system of the unmanned food processing machine is controlled by the control unit. When a power failure is detected during machine operation, all peripheral devices of the control unit except the cup lid control system can be set to low Power consumption state, for example, turning off other circuits except the lid switching system (the circuit for opening and closing the lid) to save power. At the same time, the power supply circuit can be isolated by diodes to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com