Straight jaw bone plate and manufacturing method thereof

A manufacturing method and technology of bone plate, applied in the field of medical devices, can solve the problems of manual processing of orthognathic plate, difficult to operate, lack of individualization, etc., to reduce operation time and operation difficulty, save waste, and avoid trauma and pain. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

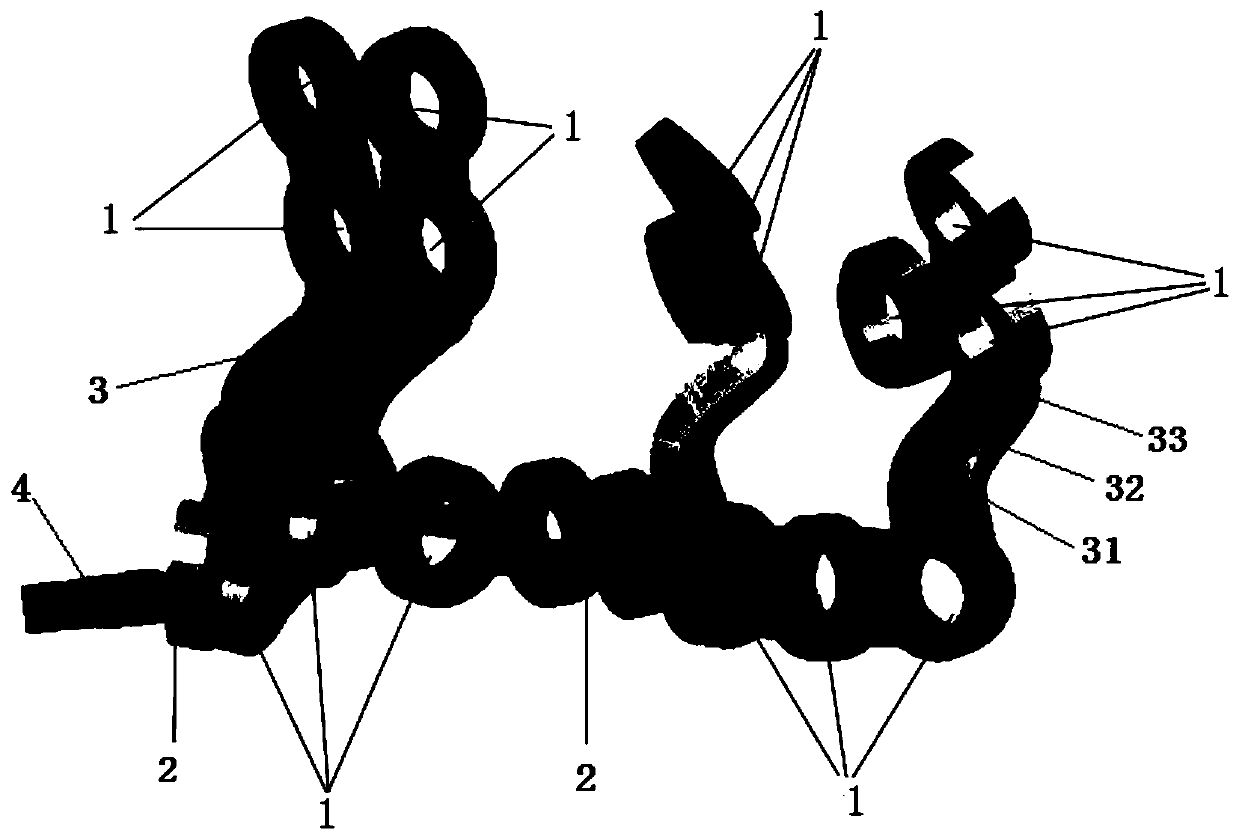

[0049] Taking the front of the jaw as a frame of reference, the side of the orthognathic plate close to the jaw is the medial side, and the side away from the jaw is the outer side. Such as Figure 1a-2 As shown, the connecting strut of the orthognathic bone plate includes a first round hole extension, a second round hole extension and a bending plate 3, the first round hole extension is located below the second round hole extension and is located in the second circle On the front side of the hole extension part, the bending plate 3 is connected between the upper and lower round hole extension parts, and the round hole extension part is composed of a plurality of round hole parts 1 connected by connecting pieces. The middle connecting plate 4 is V-shaped, and the curved surface of the inner surface of the middle connecting plate is adapted to the shape of the curved surface of the jawbone, so that the inner surface of the middle connecting plate can fit the surface of the jawb...

Embodiment 2

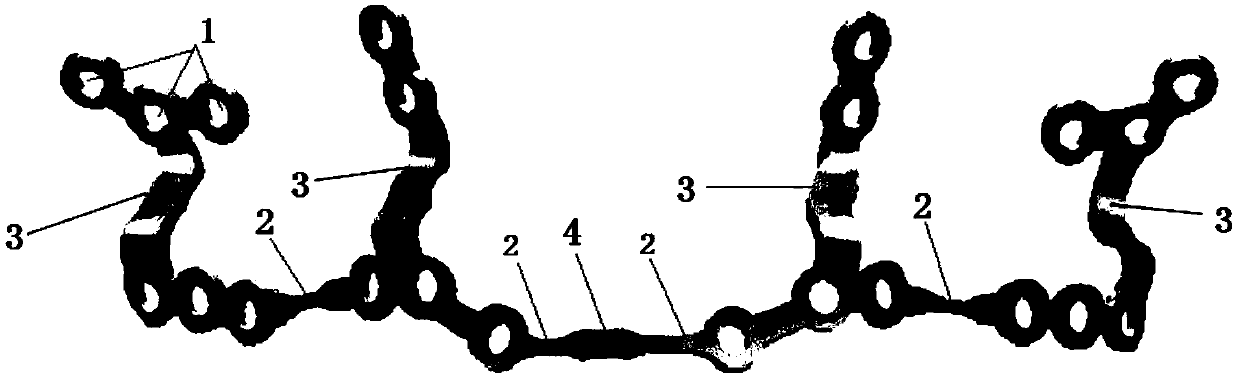

[0057] Such as Figure 3a-4 As shown, the structure of the orthognathic osteosynthesis plate described in this embodiment is substantially the same as that of the orthognathic osteosynthesis plate in Embodiment 1. The difference from Embodiment 1 is that the bending plate 3 of each connecting strut plate in this embodiment The first bending portion 31 has a large degree of bending, and the connecting portion 32 of the bending plate 3 is relatively long. For the two connecting support plates close to the middle connecting plate 4, the length of the connecting piece between the round hole 1 closest to the middle connecting part 4 and its adjacent round hole 1 in the first round hole extension part is longer than the other The length of the connecting piece between adjacent round hole parts 1.

Embodiment 3

[0059] Such as Figure 5a-6 As shown, the structure of the orthognathic bone plate described in this example is substantially the same as that in Example 2, and the difference between Example 3 and Example 2 is that in this example, the bends of the connecting struts The first bending portion 31 of the folding plate 3 is bent outwards with a small degree of curvature. In each connecting support plate, in the first round hole extension portion, the length of the connecting piece between each round hole portion 1 is the same.

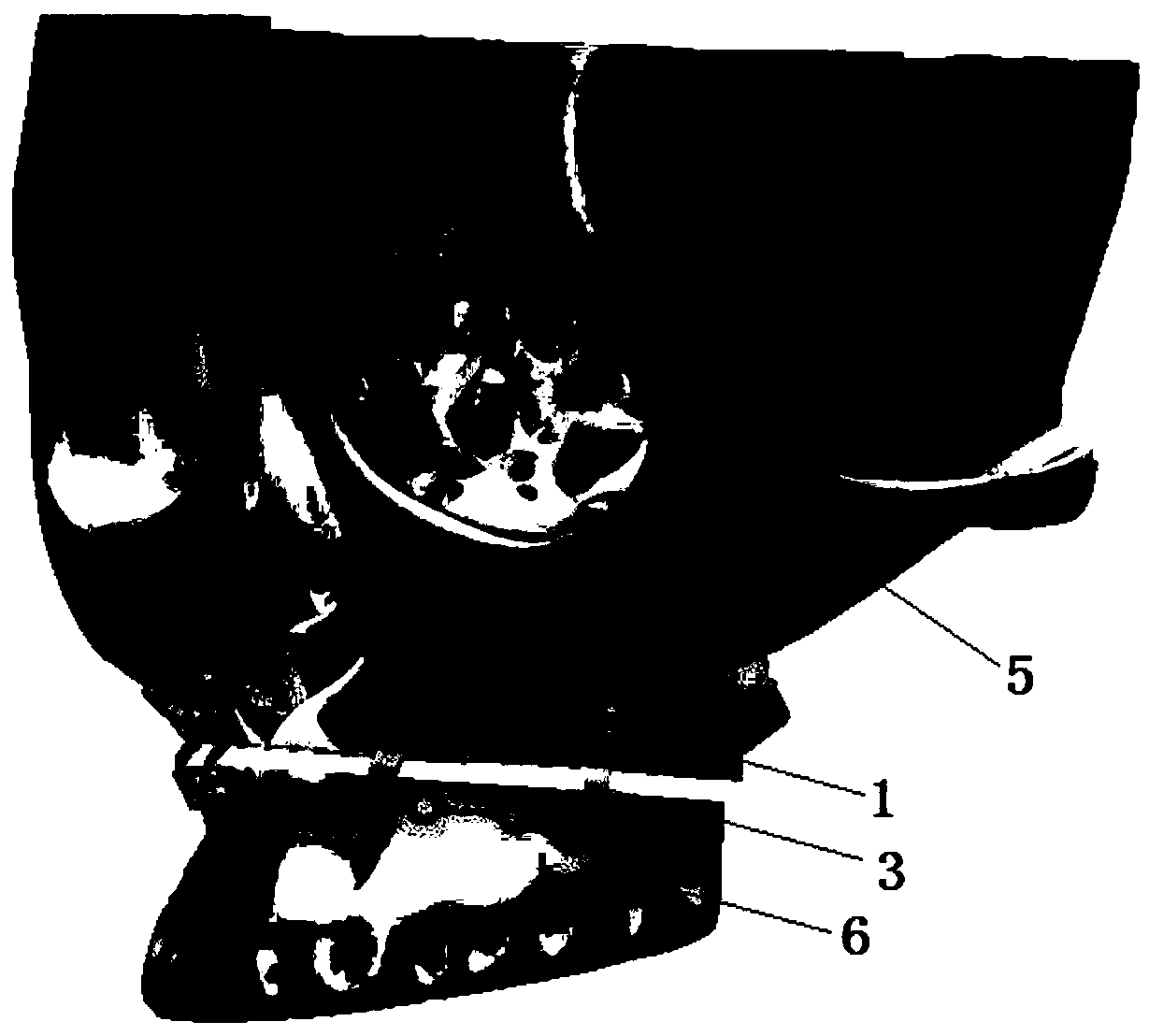

[0060] Such as figure 2 , Figure 4 with Image 6 As shown, before using the orthognathic bone plate of the present invention, the skull needs to be divided, that is, divided into the main body part 5 of the jaw and the divided part 6 of the jaw, which needs to be divided using a surgical guide plate. The structure of the specific surgical guide plate is as follows: Figure 7 As shown, the surgical guide plate includes a bone tissue fitting part 7 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com