Pipe bulging method and die based on volume expansion force

A volume expansion, pipe technology, applied in forming tools, manufacturing tools, metal processing equipment, etc., can solve the problems of unsuitability for new products, long development cycle, complex control system, etc., to shorten the trial production cycle and reduce development costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

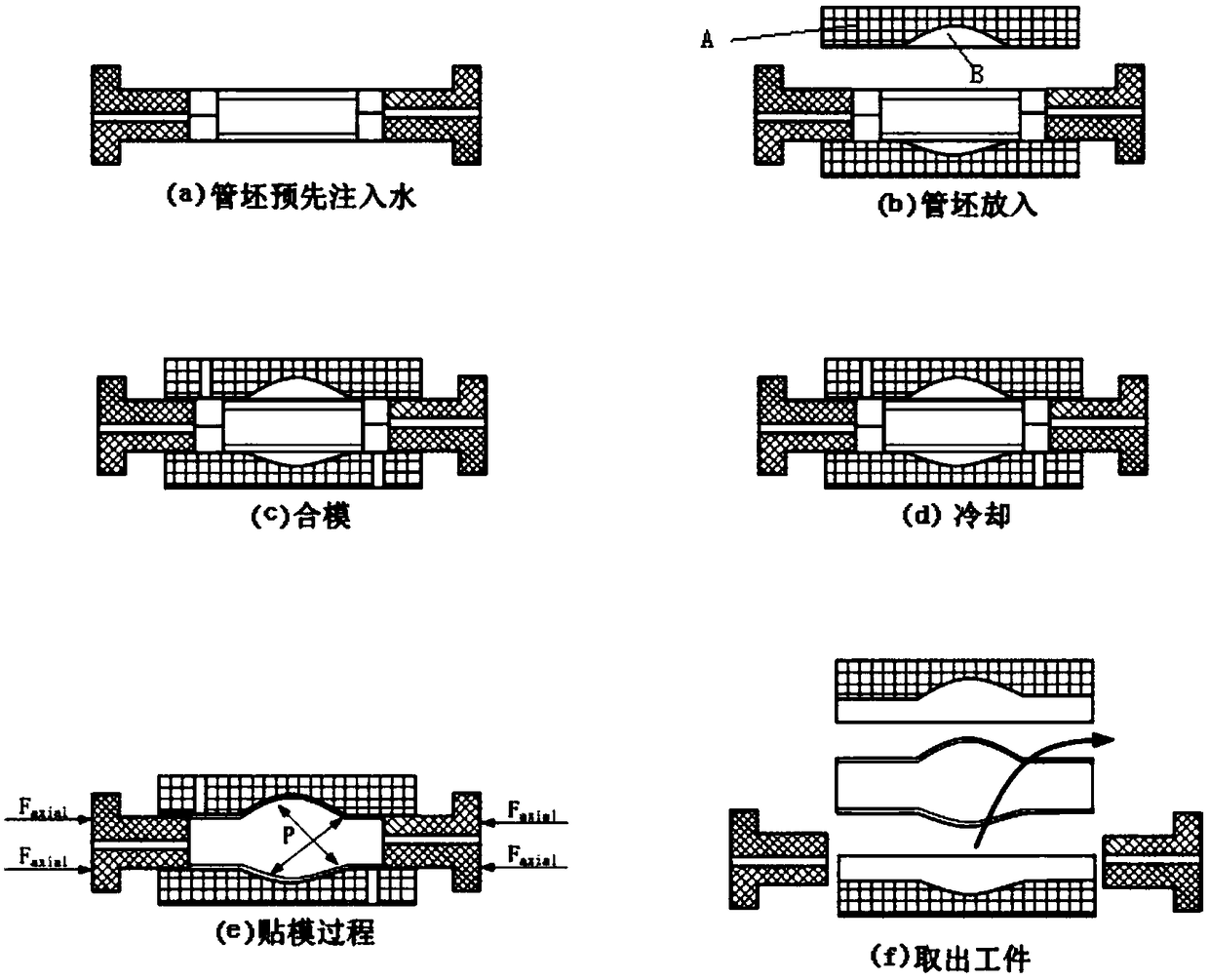

[0028] Such as figure 1 As shown, the present invention is a pipe bulging method based on volume expansion force, including: filling the sealed pipe with water, cooling the water to freeze, and expanding the pipe into the required shape under the guidance of the cavity of the mold.

[0029] The specific steps are:

[0030] (1) Fill the pipe with room temperature water in advance, and seal both ends, see figure 1 In step a;

[0031] (2) Put the pipe pre-filled with normal temperature water into the mold with a cavity, the mold is closed, and cooled. During the cooling process, the water slowly freezes, and the resulting volume bulging force bulges the pipe , see figure 1 In steps b, c, d, e;

[0032] (3) After the pipe expands...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com