Adjustable pitch propeller hub with rear-mounted oil cylinder

A rear-mounted oil cylinder technology, which is applied in the direction of ship propulsion, ship parts, ships, etc., can solve the problems of inconvenient replacement of oil cylinder seals, high working oil pressure, small area of oil cylinder piston, etc., and achieve reasonable structure, low working oil pressure, The effect of increasing the piston area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

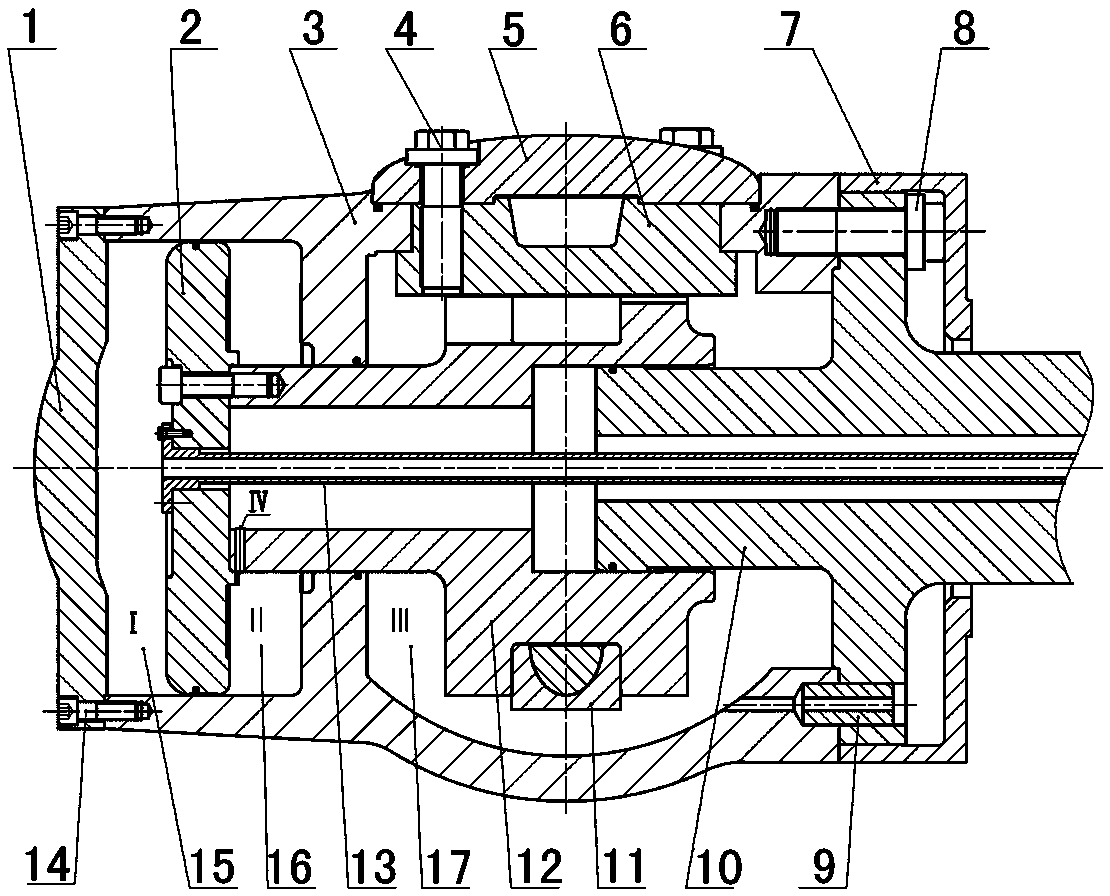

[0013] Embodiment: The present invention mainly includes rear cover plate 1, piston 2, propeller hub body 3, propeller seat 6, flange cover 7, flange bolt 8, flange pin 9, propeller shaft 10 with single oil pipe, slide Block 11, guide frame 12, inner oil pipe 13, bolt 14. The oil cylinder is located at the rear end of the propeller hub and is integrated with the propeller hub body 1, which saves the flange of the oil cylinder body, expands the area of the piston, and greatly reduces the working oil pressure. The inner oil pipe 13 is provided in the middle hole of the paddle shaft 10, the inner oil pipe 13 is connected with the piston 2 and the oil distributor, and the working oil in the oil distributor enters the rear oil chamber I through the inner oil pipe 13 to push the piston 2 and the guide frame 12 move forward together, the guide frame moves forward to drive the slider 11 to move, and the slider 11 drives the blade holder 6 to rotate through the crank pin at the botto...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com