Loading system and method

A component and transmission mechanism technology, applied in the direction of transportation and packaging, loading/unloading, object stacking, etc., can solve the problems of difficult automatic warehouse docking, low work efficiency, high labor cost, etc., to improve transmission efficiency and stability, The effect of improving loading efficiency and improving quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

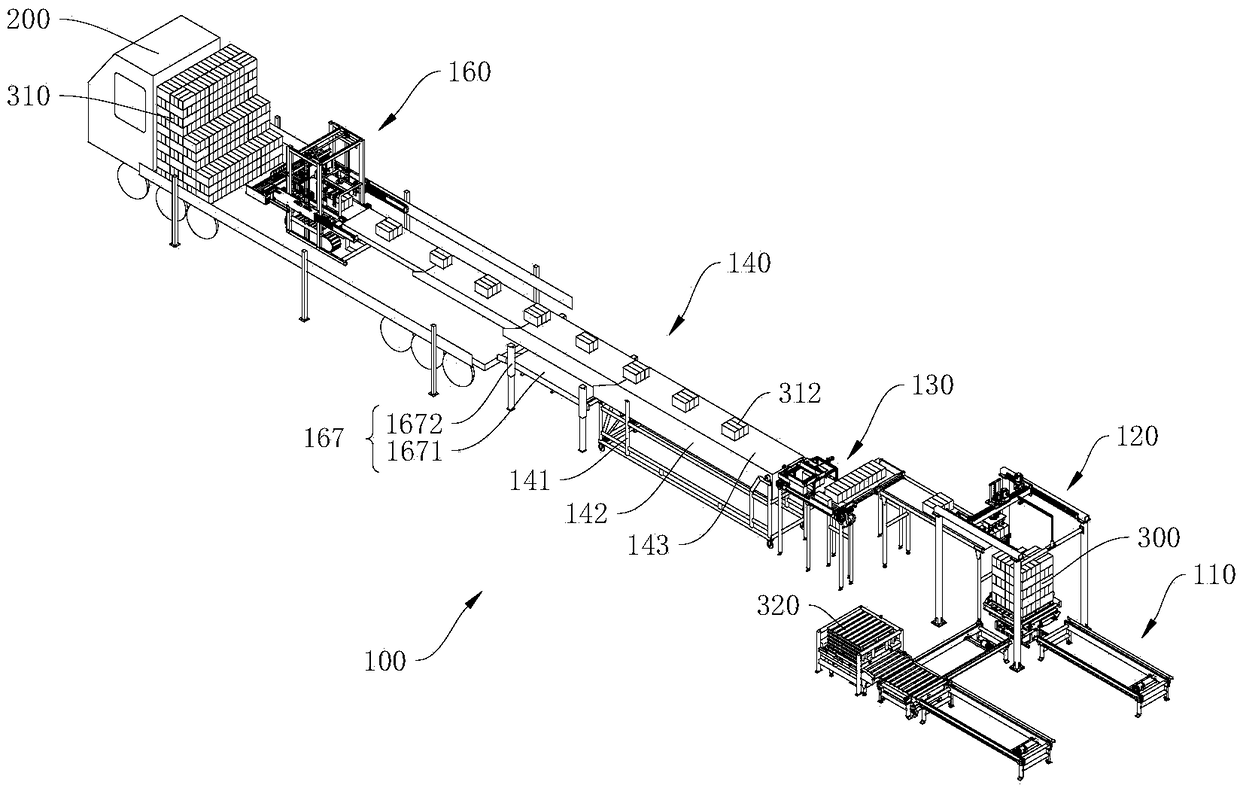

[0039] See figure 1 , figure 1 It is a schematic structural diagram of the loading system 100 provided by the first embodiment of the present invention.

[0040] The loading system 100 is used to transfer the stacks 300 from the warehouse. During the transfer process, the stacks 300 are unstacked and grouped, and the goods 310 are arranged in rows before loading to facilitate the stacking in rows. For goods 310, the loading system 100 has a high degree of automation, and has high loading quality and loading efficiency.

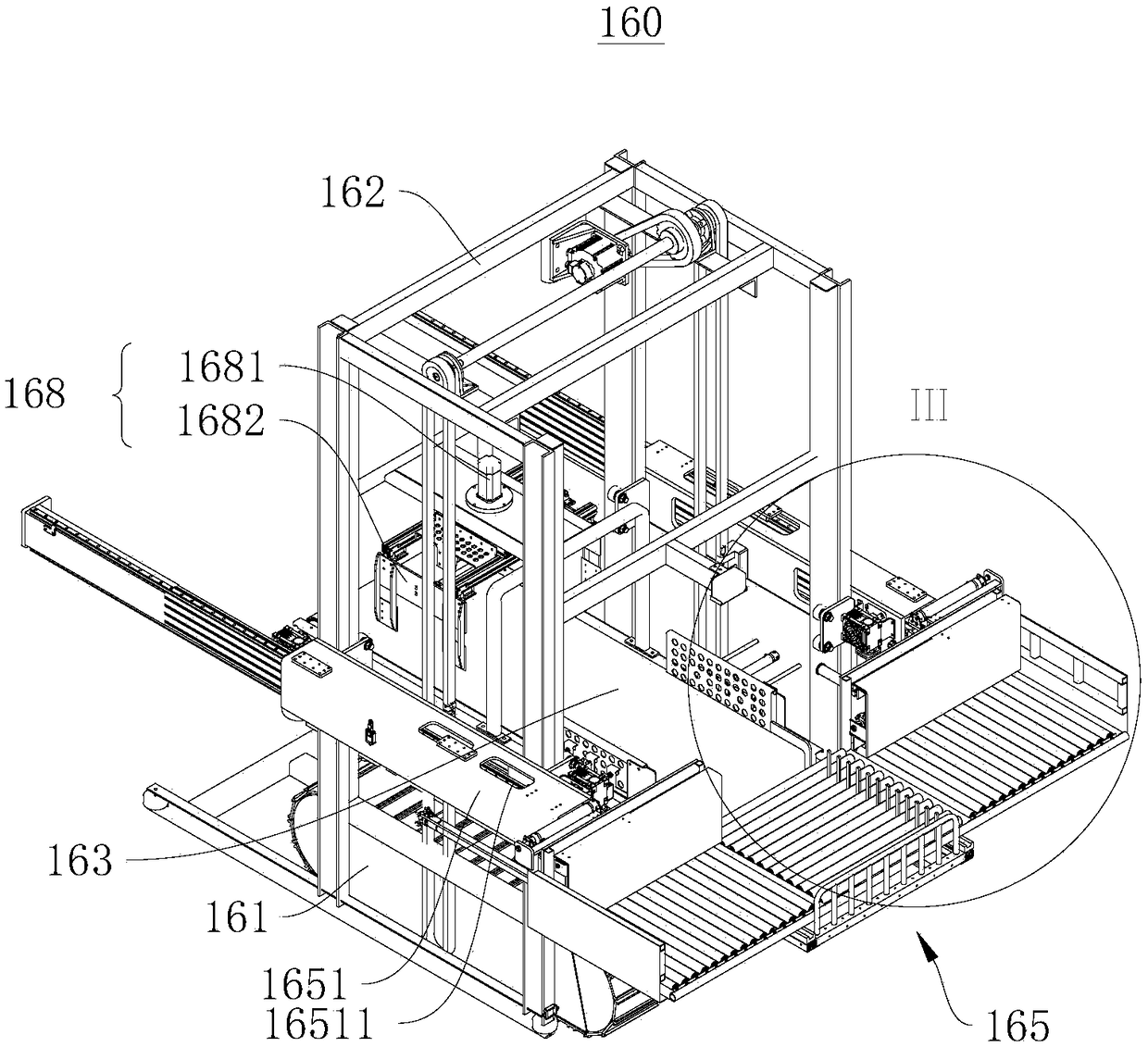

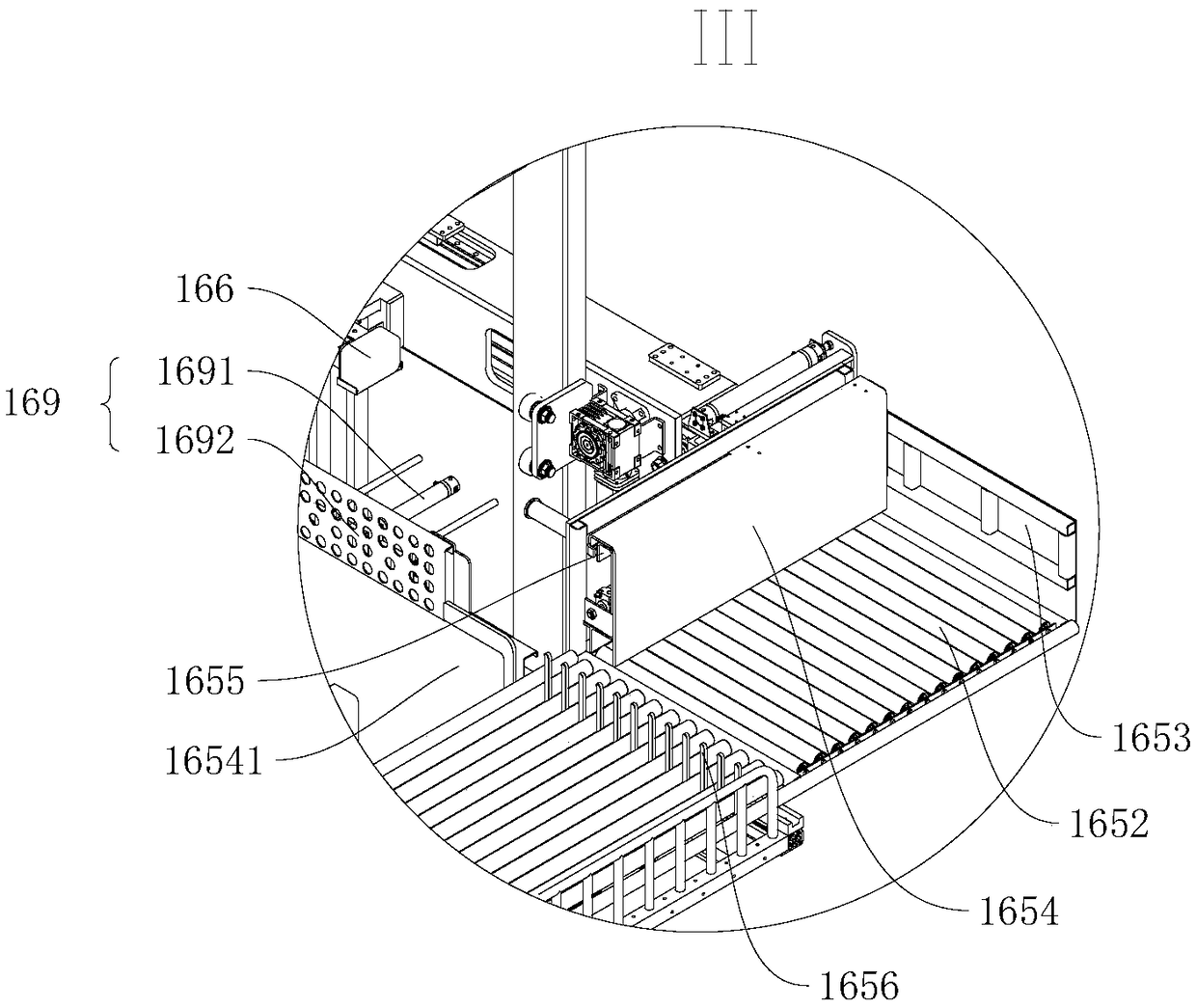

[0041] The loading system 100 includes the unloading and unstacking transfer assembly 110, the unstacking assembly 120, the box assembly component 130, the telescopic transfer mechanism 140, and the loading assembly 160 that are connected in sequence, and the unloading and unstacking transfer assembly 110 and the unstacking assembly respectively. 120. A loading control system (not shown) electrically connected to the box assembly component 130, the telescopic trans...

no. 2 example

[0097] Please refer to Figure 7 , Figure 7 It is a schematic flow chart of the loading method provided by the second embodiment of the present invention.

[0098] The loading method includes:

[0099] Step S101: Transfer the box assembly 312 or the goods 310 to the loading assembly 160 through the telescopic transfer mechanism 140;

[0100] Step S102: Receive the box assembly 312 or the goods 310 through the loading component 160, and place the box assembly 312 or the goods 310 in a row in the carriage 200.

[0101] Please refer to Figure 8 , Figure 8 It is a schematic diagram of another flow of the loading method provided by the second embodiment of the present invention.

[0102] Before step S101, the loading method further includes:

[0103] Step S103: Transfer the stack 300 from the warehouse to the unstacking component 120 through the outbound and return transfer component 110;

[0104] Step S104: receiving the stack 300 through the unstacking component 120, picking up the good...

no. 3 example

[0111] In this embodiment, a logistics management system (not shown) is provided. The logistics management system adopts the loading system 100 provided in the first embodiment, and the central server (not shown) is electrically connected to the loading control system. The logistics management system can realize continuous delivery of goods 310 and automatic loading, with a high degree of automation, stable loading quality and high efficiency.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com