Hydraulic winch driving mechanism

A driving mechanism, hydraulic technology, applied in hoisting device, clockwork mechanism, etc., can solve the problems of large safety accidents of reducers, low efficiency of judging fault points, and only shutdown for replacement, so as to reduce procurement costs and benefit Effect of individual control and redundant design, shortening procurement cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

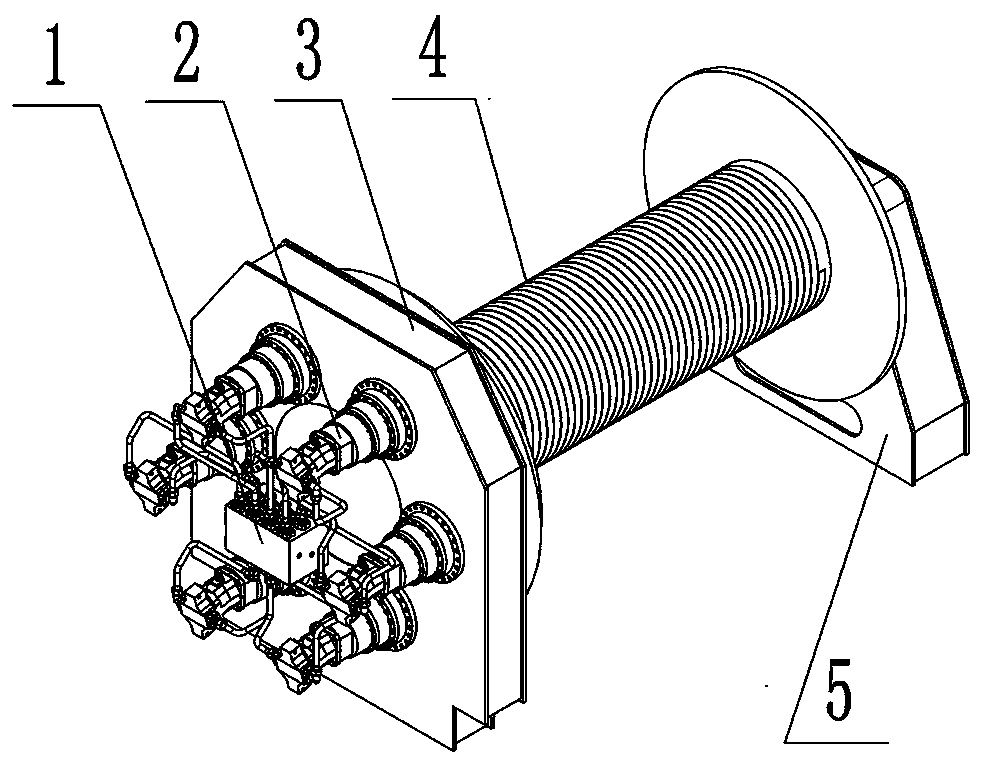

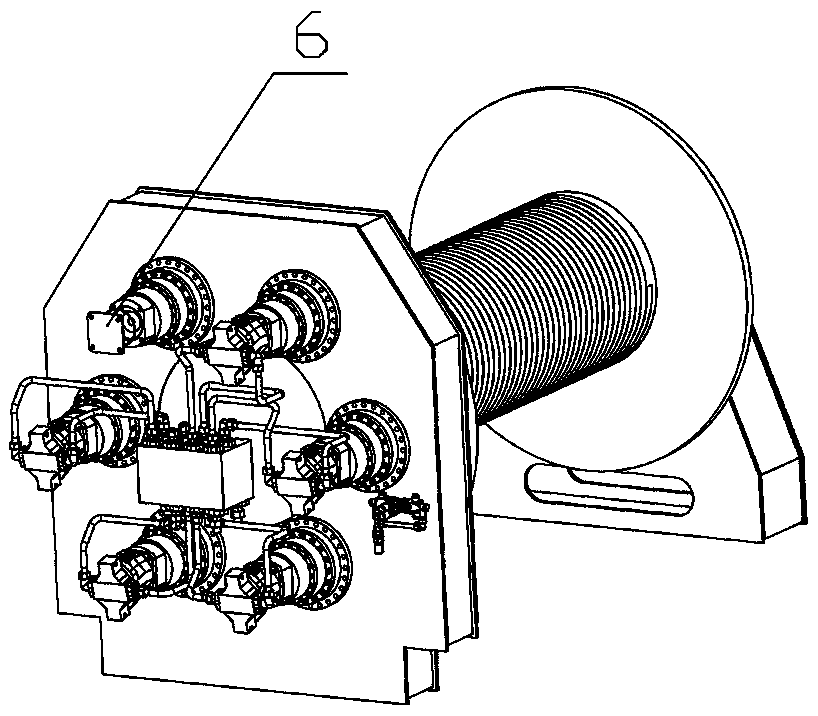

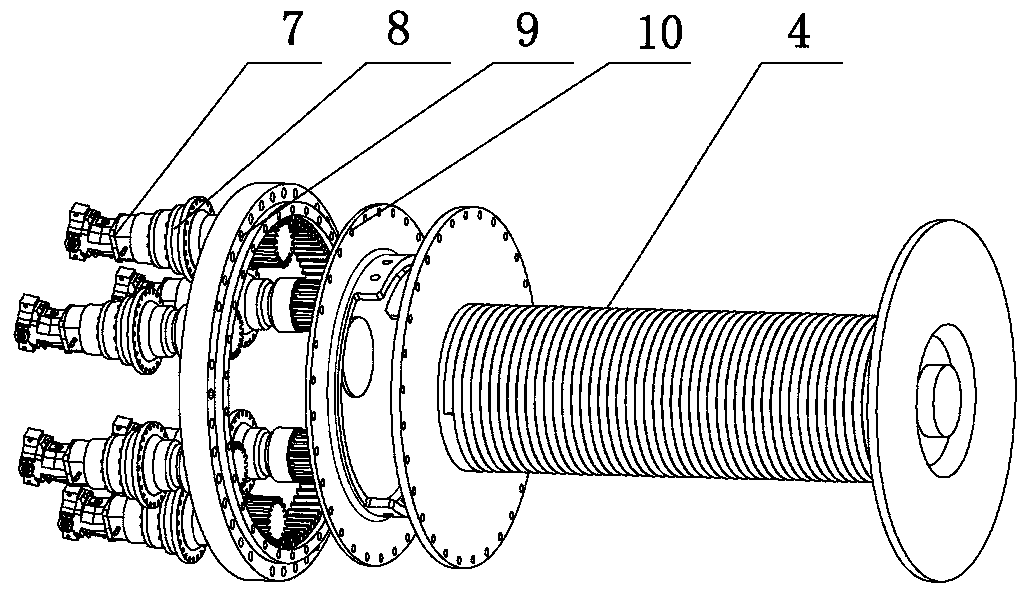

[0015] Before the implementation of the present invention, it is necessary to calculate the overall torque, select models according to parameters, and match the number of local drives (including actual drives and backup drives). The hydraulic winch driving mechanism is composed of a hydraulic control valve 1 , a driving unit 2 , a structural frame 3 , a reel 4 , a bearing bracket 5 , and a blocking element 6 . The hydraulic motor 7 and the reducer 8 are installed together to form an independent drive unit 2, and the reducer 8 is inserted into the structural frame 3 on the driving side of the reel 4; there is a rotary roller 9 inside the structural frame 3, and each drive unit decelerates The shaft head gear of machine 8 meshes with the internal teeth of the large ring gear of the rotary roller 9, and the large ring gear of the rotary roller 9 drives the adapter plate 10 fixedly connected with the reel 4 driving side plates to rotate.

[0016] The drive units fixed on the struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com